What is Global Oil Mist Extraction System Market?

The Global Oil Mist Extraction System Market refers to the industry focused on the development, production, and distribution of systems designed to remove oil mist from the air in various industrial settings. Oil mist is a byproduct of machining processes, lubrication, and other industrial activities that involve the use of oil. These systems are crucial for maintaining a clean and safe working environment, as oil mist can pose significant health risks to workers and can also damage machinery and equipment. The market encompasses a range of technologies and solutions, including electrostatic precipitation, mechanical filtration, and centrifugal separation, each with its own advantages and applications. The demand for oil mist extraction systems is driven by stringent environmental regulations, the need for improved workplace safety, and the desire to enhance the longevity and efficiency of industrial equipment. As industries continue to grow and evolve, the importance of effective oil mist extraction systems is expected to increase, making this market a vital component of modern industrial operations.

Electrostatic Precipitation (ESP), Mechanical Filtration in the Global Oil Mist Extraction System Market:

Electrostatic Precipitation (ESP) and Mechanical Filtration are two primary technologies used in the Global Oil Mist Extraction System Market. Electrostatic Precipitation (ESP) works by charging the oil mist particles as they pass through an ionization field. These charged particles are then attracted to and collected on oppositely charged plates or surfaces. ESP systems are highly efficient and can capture very fine particles, making them suitable for applications where high levels of filtration are required. They are also relatively low maintenance, as the collected oil can be periodically removed from the collection plates. However, ESP systems can be more expensive to install and operate compared to other methods. On the other hand, Mechanical Filtration involves the use of physical barriers, such as filters made of various materials, to capture oil mist particles. These filters can range from simple mesh screens to more complex multi-layered filters designed to capture particles of different sizes. Mechanical filtration systems are generally more straightforward and less expensive than ESP systems, but they may require more frequent maintenance and filter replacements. They are effective for capturing larger particles and are commonly used in applications where the oil mist is relatively coarse. Both technologies have their own set of advantages and are chosen based on the specific needs and conditions of the industrial environment. The choice between ESP and Mechanical Filtration often depends on factors such as the size and concentration of the oil mist particles, the required level of filtration efficiency, and the budget available for installation and maintenance. In some cases, a combination of both technologies may be used to achieve optimal results. As industries continue to prioritize worker safety and equipment longevity, the demand for advanced oil mist extraction systems incorporating these technologies is expected to grow.

Automotive, Heavy Industry, Machine Manafacturing, Others in the Global Oil Mist Extraction System Market:

The usage of Global Oil Mist Extraction System Market spans across various industries, including Automotive, Heavy Industry, Machine Manufacturing, and others. In the Automotive industry, oil mist extraction systems are essential for maintaining a clean and safe working environment in manufacturing plants and workshops. These systems help to remove oil mist generated during machining, grinding, and other processes, thereby protecting workers from respiratory issues and preventing the accumulation of oil on machinery and surfaces. This not only enhances worker safety but also improves the efficiency and longevity of the equipment. In Heavy Industry, oil mist extraction systems play a crucial role in large-scale operations such as metalworking, mining, and power generation. These industries often involve high levels of oil mist production, and effective extraction systems are necessary to comply with environmental regulations and ensure the safety of workers. The systems help to reduce the risk of fire hazards, improve air quality, and minimize the impact of oil mist on the surrounding environment. In Machine Manufacturing, oil mist extraction systems are used to maintain a clean and controlled environment in production facilities. The systems help to remove oil mist generated during machining, cutting, and other processes, thereby preventing contamination of the products and ensuring high-quality manufacturing standards. This is particularly important in precision manufacturing, where even small amounts of oil mist can affect the quality and performance of the final products. Other industries that benefit from oil mist extraction systems include food processing, pharmaceuticals, and electronics manufacturing. In these industries, maintaining a clean and contaminant-free environment is critical to ensuring product quality and safety. Oil mist extraction systems help to achieve this by effectively removing oil mist and other airborne contaminants from the production environment. Overall, the usage of oil mist extraction systems is essential for maintaining a safe, clean, and efficient working environment across various industries. As the demand for high-quality products and stringent environmental and safety regulations continue to grow, the importance of effective oil mist extraction systems is expected to increase.

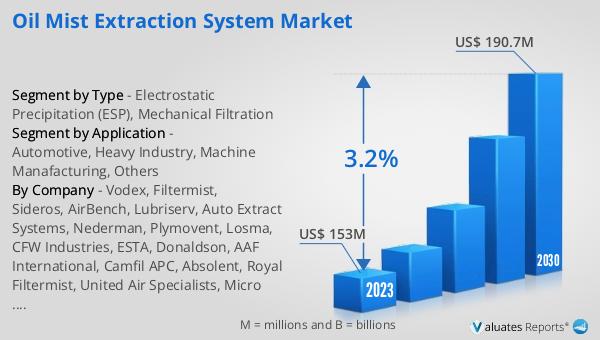

Global Oil Mist Extraction System Market Outlook:

The global Oil Mist Extraction System market was valued at US$ 153 million in 2023 and is anticipated to reach US$ 190.7 million by 2030, witnessing a CAGR of 3.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by increasing awareness of workplace safety and stringent environmental regulations. The rising demand for efficient and reliable oil mist extraction systems across various industries, including automotive, heavy industry, and machine manufacturing, is expected to fuel this growth. Companies are investing in advanced technologies and innovative solutions to meet the evolving needs of their customers and comply with regulatory standards. The market is also witnessing a shift towards more sustainable and energy-efficient systems, as industries seek to reduce their environmental footprint and operational costs. As a result, the global Oil Mist Extraction System market is poised for significant growth in the coming years, driven by technological advancements, regulatory pressures, and the increasing focus on worker safety and environmental sustainability.

| Report Metric | Details |

| Report Name | Oil Mist Extraction System Market |

| Accounted market size in 2023 | US$ 153 million |

| Forecasted market size in 2030 | US$ 190.7 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vodex, Filtermist, Sideros, AirBench, Lubriserv, Auto Extract Systems, Nederman, Plymovent, Losma, CFW Industries, ESTA, Donaldson, AAF International, Camfil APC, Absolent, Royal Filtermist, United Air Specialists, Micro Air, Filter 1, MistBuster, Airflow Systems, Coral, Aeroex Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |