What is Glass Quality Testing - Global Market?

Glass quality testing is a crucial aspect of ensuring the safety, durability, and performance of glass products across various industries. This global market involves a range of testing methods and technologies designed to assess the quality of glass materials used in construction, automotive, electronics, and other sectors. The primary goal of glass quality testing is to identify any defects or weaknesses in the glass that could compromise its structural integrity or functionality. This includes evaluating factors such as transparency, strength, thickness, and resistance to thermal and mechanical stress. By conducting thorough quality assessments, manufacturers can ensure that their glass products meet industry standards and regulatory requirements, thereby minimizing the risk of product failures and enhancing customer satisfaction. The global market for glass quality testing is driven by the increasing demand for high-quality glass products, advancements in testing technologies, and the growing emphasis on safety and sustainability in various industries. As a result, this market is expected to continue expanding, offering numerous opportunities for companies involved in the development and implementation of glass testing solutions.

Design and Visual Examinations, Annealing Assessments (Residual Stress), Glass Thickness and Weight Measurements, Thermal Shock or Impact Testing in the Glass Quality Testing - Global Market:

Design and visual examinations are fundamental components of glass quality testing, focusing on the aesthetic and structural aspects of glass products. These examinations involve inspecting the glass for any visible defects, such as scratches, bubbles, or inclusions, that could affect its appearance or performance. By using advanced imaging technologies and trained inspectors, manufacturers can identify and address these issues early in the production process, ensuring that the final product meets the desired quality standards. Annealing assessments, on the other hand, are crucial for evaluating the residual stress within the glass. This process involves heating the glass to a specific temperature and then gradually cooling it to relieve internal stresses that could lead to cracking or breaking. By conducting annealing assessments, manufacturers can ensure that their glass products have the necessary strength and durability to withstand various environmental conditions. Glass thickness and weight measurements are also essential aspects of quality testing, as they directly impact the glass's performance and safety. Accurate measurements are crucial for ensuring that the glass meets the required specifications and can support the intended load without compromising its structural integrity. Thermal shock or impact testing is another critical component of glass quality testing, designed to evaluate the glass's ability to withstand sudden temperature changes or mechanical impacts. This testing involves subjecting the glass to extreme conditions and assessing its response to determine its resilience and reliability. By conducting these tests, manufacturers can ensure that their glass products are capable of withstanding the rigors of real-world applications, thereby enhancing their safety and performance. Overall, these testing methods play a vital role in the global market for glass quality testing, helping manufacturers produce high-quality glass products that meet industry standards and customer expectations.

Construction Glass, Industrial Glass, Specialty Glass, Quartz Glass in the Glass Quality Testing - Global Market:

Glass quality testing plays a significant role in various sectors, including construction, industrial, specialty, and quartz glass applications. In the construction industry, glass quality testing is essential for ensuring the safety and durability of glass used in buildings and infrastructure projects. This includes testing for factors such as strength, transparency, and resistance to environmental conditions, which are crucial for maintaining the structural integrity and aesthetic appeal of buildings. In the industrial sector, glass quality testing is vital for ensuring the performance and reliability of glass components used in machinery, equipment, and other industrial applications. This involves evaluating the glass's ability to withstand mechanical stress, thermal fluctuations, and chemical exposure, which are common in industrial environments. Specialty glass, which includes products such as tempered, laminated, and coated glass, also relies heavily on quality testing to ensure its unique properties and performance characteristics. This involves assessing factors such as impact resistance, thermal insulation, and UV protection, which are critical for meeting the specific requirements of various applications. Quartz glass, known for its exceptional thermal and optical properties, is used in high-tech industries such as electronics, telecommunications, and scientific research. Quality testing for quartz glass involves evaluating its purity, transparency, and resistance to thermal and chemical stress, which are essential for ensuring its performance in demanding applications. Overall, glass quality testing is a critical component of the global market, ensuring that glass products meet the necessary standards and requirements for their intended use across various industries.

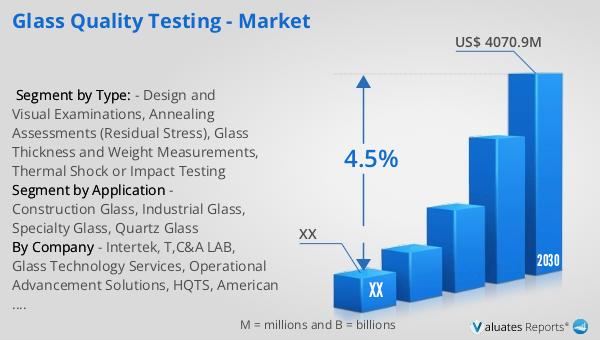

Glass Quality Testing - Global Market Outlook:

The global market for glass quality testing was valued at approximately $3,001 million in 2023. It is projected to grow to a revised size of around $4,070.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality glass products across various industries, advancements in testing technologies, and the growing emphasis on safety and sustainability. As industries continue to prioritize quality and performance, the demand for comprehensive glass testing solutions is expected to rise, offering significant opportunities for companies involved in this market. The expansion of the glass quality testing market is also supported by the increasing adoption of advanced testing methods and technologies, which enable manufacturers to conduct more accurate and efficient assessments of their glass products. This, in turn, helps them meet industry standards and regulatory requirements, thereby enhancing their competitiveness in the global market. Overall, the glass quality testing market is poised for steady growth, driven by the ongoing demand for high-quality glass products and the continuous development of innovative testing solutions.

| Report Metric | Details |

| Report Name | Glass Quality Testing - Market |

| Forecasted market size in 2030 | US$ 4070.9 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Intertek, T,C&A LAB, Glass Technology Services, Operational Advancement Solutions, HQTS, American Glass Research, SYNERGX, Eurofins Expert Services, CAS TESTING, Infinita Lab, ZVT, NCTL, TÜV Rheinland, Thomas Bell-Wright International Consultants, ERC Testing Ltd, WINDOW ENGINEERING CONSULTANTS, Dr. Schenk, ZHENGXIN JIANCE, FAIR TEST, Ceshigo, CHANGCHUNZY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |