What is Perfluoropolyether Heat transfer Fluid - Global Market?

Perfluoropolyether (PFPE) heat transfer fluid is a specialized chemical compound used in various industries for its exceptional thermal stability and non-reactive properties. These fluids are part of a broader category of synthetic oils that are designed to operate under extreme conditions, such as high temperatures and pressures, without breaking down or losing their effectiveness. PFPE heat transfer fluids are particularly valued for their ability to maintain performance in corrosive environments, making them ideal for applications where other fluids might fail. The global market for these fluids is expanding as industries increasingly demand reliable and efficient heat transfer solutions. PFPE fluids are used in a variety of sectors, including electronics, aerospace, and manufacturing, where precise temperature control is crucial. Their unique chemical structure allows them to function effectively over a wide temperature range, providing consistent thermal management. As industries continue to innovate and require more advanced materials, the demand for PFPE heat transfer fluids is expected to grow, driven by their ability to enhance operational efficiency and safety. This growth is reflected in the market's projected expansion, highlighting the importance of PFPE fluids in modern industrial applications.

Vapor Phase Fluids, Liquid Phase Fluids in the Perfluoropolyether Heat transfer Fluid - Global Market:

Vapor phase and liquid phase fluids based on Perfluoropolyether (PFPE) heat transfer fluids are integral to various industrial processes, each serving distinct roles depending on the application requirements. Vapor phase fluids are typically used in applications where rapid heat transfer is necessary. These fluids operate by changing phase from liquid to vapor, absorbing heat in the process, and then releasing it upon condensation. This phase change allows for efficient heat transfer, making vapor phase fluids ideal for applications such as semiconductor manufacturing and electronic cooling systems. In semiconductor wafer manufacturing, for instance, the precise control of temperature is crucial to ensure the quality and performance of the wafers. Vapor phase PFPE fluids provide the necessary thermal management by efficiently transferring heat away from sensitive components, thus preventing overheating and ensuring consistent production quality. On the other hand, liquid phase PFPE fluids are used in applications where a stable and continuous heat transfer medium is required. These fluids remain in the liquid state throughout the process, providing a consistent thermal management solution. Liquid phase PFPE fluids are often used in systems where maintaining a specific temperature is critical, such as in data centers and electronic reliability testing. In data centers, for example, the continuous operation of servers generates significant heat, which needs to be effectively managed to prevent system failures. Liquid phase PFPE fluids circulate through the cooling systems, absorbing and dissipating heat to maintain optimal operating temperatures. Similarly, in electronic reliability testing, maintaining a stable temperature is essential to ensure accurate test results and the longevity of electronic components. The choice between vapor phase and liquid phase PFPE fluids depends on the specific requirements of the application, including the desired rate of heat transfer, operating temperature range, and system design. Both types of fluids offer unique advantages, with vapor phase fluids providing rapid heat transfer through phase change and liquid phase fluids offering consistent thermal management. As industries continue to evolve and demand more efficient and reliable heat transfer solutions, the use of PFPE-based fluids is expected to increase, driven by their ability to enhance performance and safety in critical applications.

Semiconductor Wafer Manufacturing, Electronic Reliability Test, Data Center, Other in the Perfluoropolyether Heat transfer Fluid - Global Market:

Perfluoropolyether (PFPE) heat transfer fluids are extensively used in various high-tech industries due to their exceptional thermal stability and non-reactive nature. In semiconductor wafer manufacturing, PFPE fluids play a crucial role in maintaining the precise temperature control required during the production process. The manufacturing of semiconductor wafers involves several stages where temperature fluctuations can significantly impact the quality and performance of the final product. PFPE fluids, with their ability to operate under extreme temperatures and pressures, ensure that the heat generated during these processes is efficiently managed, thereby preventing overheating and ensuring consistent wafer quality. In electronic reliability testing, PFPE fluids are used to maintain stable temperatures during the testing of electronic components. These tests are essential to determine the durability and performance of electronic devices under various conditions. PFPE fluids provide the necessary thermal management to ensure that the components are tested accurately, without the risk of temperature-induced failures. In data centers, the continuous operation of servers generates substantial heat, which needs to be effectively managed to prevent system failures and ensure optimal performance. PFPE fluids are used in the cooling systems of data centers to absorb and dissipate heat, maintaining the servers at optimal operating temperatures. This not only enhances the efficiency of the data centers but also extends the lifespan of the servers by preventing overheating. Additionally, PFPE fluids are used in other applications where precise temperature control is essential, such as in aerospace and automotive industries. Their ability to function effectively in corrosive environments and under extreme conditions makes them ideal for use in these demanding applications. As industries continue to innovate and require more advanced materials, the demand for PFPE heat transfer fluids is expected to grow, driven by their ability to enhance operational efficiency and safety in critical applications.

Perfluoropolyether Heat transfer Fluid - Global Market Outlook:

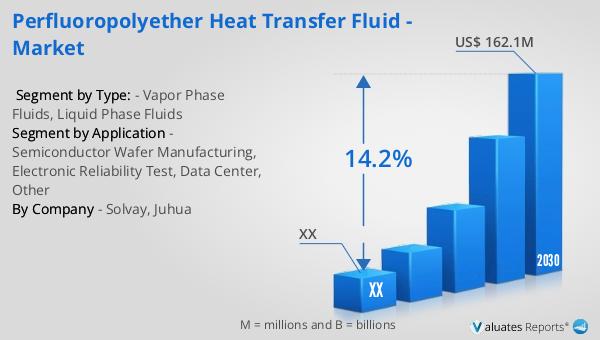

The global market for Perfluoropolyether (PFPE) heat transfer fluid was valued at approximately $55 million in 2023. It is anticipated to grow significantly, reaching an estimated size of $162.1 million by 2030, with a compound annual growth rate (CAGR) of 14.2% during the forecast period from 2024 to 2030. This growth is largely attributed to the unique properties of PFPE heat transfer fluids, which include high thermal stability and resistance to decomposition under extreme temperatures, pressures, and corrosive environments. These characteristics make PFPE fluids highly desirable in industries that require reliable and efficient heat transfer solutions. The increasing demand for advanced thermal management systems in sectors such as electronics, aerospace, and manufacturing is driving the market expansion. PFPE fluids are particularly valued for their ability to maintain performance in challenging conditions, ensuring the safety and efficiency of industrial processes. As industries continue to evolve and require more sophisticated materials, the market for PFPE heat transfer fluids is expected to grow, reflecting their importance in modern industrial applications. This projected growth underscores the critical role that PFPE fluids play in enhancing operational efficiency and safety across various sectors.

| Report Metric | Details |

| Report Name | Perfluoropolyether Heat transfer Fluid - Market |

| Forecasted market size in 2030 | US$ 162.1 million |

| CAGR | 14.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Solvay, Juhua |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |