What is Hard Coatings for Lenses - Global Market?

Hard coatings for lenses are specialized protective layers applied to optical lenses to enhance their durability and performance. These coatings are designed to resist scratches, abrasions, and other forms of wear and tear that lenses might encounter during everyday use. The global market for hard coatings for lenses is driven by the increasing demand for high-quality eyewear and optical devices. As consumers become more aware of the benefits of durable lenses, manufacturers are investing in advanced coating technologies to meet these expectations. Hard coatings not only extend the lifespan of lenses but also improve their optical clarity, making them essential for both prescription glasses and camera lenses. The market is characterized by continuous innovation, with companies striving to develop coatings that offer superior protection without compromising on lens transparency. As a result, the global market for hard coatings for lenses is poised for significant growth, driven by technological advancements and the rising demand for premium optical products.

Heat Cured Hard Coat, UV Hard Coating in the Hard Coatings for Lenses - Global Market:

Heat-cured hard coats and UV hard coatings are two prominent types of protective layers used in the global market for hard coatings for lenses. Heat-cured hard coats are applied to lenses through a process that involves heating the coating material to a specific temperature, allowing it to form a robust and durable layer. This method is known for producing coatings with excellent adhesion and scratch resistance, making it a popular choice for high-performance lenses. The heat-curing process ensures that the coating bonds effectively with the lens material, providing long-lasting protection against physical damage. On the other hand, UV hard coatings are applied using ultraviolet light to cure the coating material. This method is faster and more energy-efficient compared to heat curing, as it does not require high temperatures. UV hard coatings are particularly advantageous for lenses that need to maintain their optical clarity while being protected from scratches and abrasions. The UV curing process allows for precise control over the coating thickness, ensuring uniform coverage and optimal performance. Both heat-cured and UV hard coatings are essential in the production of lenses that require enhanced durability and optical performance. They are widely used in various applications, including eyewear, camera lenses, and optical instruments, where lens protection is crucial. The choice between heat-cured and UV hard coatings depends on factors such as the desired level of protection, production efficiency, and cost considerations. Manufacturers often select the coating method that best aligns with their specific requirements and production capabilities. As the demand for high-quality lenses continues to grow, the global market for hard coatings is expected to expand, driven by advancements in coating technologies and the increasing need for durable optical products.

Spherical Lens, Aspherical Lens in the Hard Coatings for Lenses - Global Market:

Hard coatings for lenses play a crucial role in enhancing the performance and durability of both spherical and aspherical lenses. Spherical lenses, which have a consistent curvature across their surface, are commonly used in a variety of optical applications, including eyeglasses, cameras, and telescopes. The application of hard coatings on spherical lenses helps protect them from scratches, abrasions, and other forms of physical damage, ensuring that they maintain their optical clarity over time. These coatings also enhance the lenses' resistance to environmental factors such as dust and moisture, making them suitable for use in challenging conditions. Aspherical lenses, on the other hand, have a more complex surface curvature designed to reduce optical aberrations and improve image quality. Hard coatings are equally important for aspherical lenses, as they provide the necessary protection to maintain the lenses' precision and performance. The application of hard coatings on aspherical lenses ensures that they remain free from scratches and other imperfections that could compromise their optical properties. This is particularly important in applications where high image quality is essential, such as in professional photography and advanced optical instruments. The global market for hard coatings for lenses is driven by the increasing demand for high-performance optical products, with both spherical and aspherical lenses benefiting from the enhanced durability and protection offered by these coatings. As technology continues to advance, the development of new and improved hard coatings is expected to further enhance the performance of both spherical and aspherical lenses, meeting the growing needs of consumers and industries worldwide.

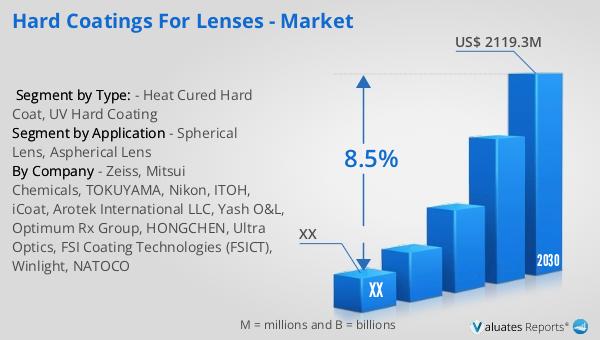

Hard Coatings for Lenses - Global Market Outlook:

In 2023, the global market for hard coatings for lenses was valued at approximately $1,120 million. This market is projected to grow significantly, reaching an estimated size of $2,119.3 million by 2030. This growth represents a compound annual growth rate (CAGR) of 8.5% during the forecast period from 2024 to 2030. The increasing demand for durable and high-quality optical lenses is a key factor driving this market expansion. As consumers become more aware of the benefits of hard coatings, such as enhanced scratch resistance and improved lens longevity, the demand for these coatings is expected to rise. Additionally, advancements in coating technologies are enabling manufacturers to develop more effective and efficient hard coatings, further fueling market growth. The growing popularity of premium eyewear and optical devices is also contributing to the increased demand for hard coatings, as consumers seek products that offer superior performance and durability. As a result, the global market for hard coatings for lenses is poised for substantial growth in the coming years, driven by technological innovations and the rising demand for high-quality optical products.

| Report Metric | Details |

| Report Name | Hard Coatings for Lenses - Market |

| Forecasted market size in 2030 | US$ 2119.3 million |

| CAGR | 8.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Zeiss, Mitsui Chemicals, TOKUYAMA, Nikon, ITOH, iCoat, Arotek International LLC, Yash O&L, Optimum Rx Group, HONGCHEN, Ultra Optics, FSI Coating Technologies (FSICT), Winlight, NATOCO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |