What is Water in Oil Sensor - Global Market?

Water in oil sensors are crucial devices used in various industries to detect the presence of water in oil, which can be detrimental to machinery and systems. These sensors are designed to provide real-time monitoring and alerts, ensuring that any water contamination is promptly addressed to prevent damage and maintain efficiency. The global market for water in oil sensors is driven by the increasing demand for efficient monitoring systems in industries such as automotive, marine, and industrial machinery. These sensors help in maintaining the quality and performance of oil by detecting water content, which can lead to corrosion, reduced lubrication, and system failures. The market is characterized by technological advancements, with manufacturers focusing on developing more accurate and reliable sensors. The adoption of these sensors is also fueled by stringent regulations and standards aimed at ensuring the safety and efficiency of machinery and equipment. As industries continue to prioritize maintenance and operational efficiency, the demand for water in oil sensors is expected to grow, making them an essential component in various applications.

Contact Sensor, Contactless Sensor in the Water in Oil Sensor - Global Market:

Contact sensors and contactless sensors are two primary types of water in oil sensors used in the global market, each with distinct features and applications. Contact sensors, as the name suggests, require direct contact with the oil to measure the water content. These sensors are typically installed in-line with the oil flow, allowing them to continuously monitor the oil's condition. They are known for their accuracy and reliability, making them suitable for applications where precise measurements are critical. Contact sensors often use capacitive or resistive measurement techniques to detect changes in the oil's dielectric properties, which indicate the presence of water. On the other hand, contactless sensors operate without direct contact with the oil. They use advanced technologies such as infrared spectroscopy or microwave resonance to detect water content. These sensors are advantageous in situations where contamination or wear and tear of the sensor is a concern, as they do not come into direct contact with the oil. Contactless sensors are often used in applications where maintenance and sensor longevity are priorities. Both types of sensors have their own set of advantages and limitations, and the choice between them depends on the specific requirements of the application. For instance, contact sensors may be preferred in environments where high accuracy is needed, while contactless sensors may be chosen for their durability and low maintenance needs. The global market for water in oil sensors is witnessing a growing trend towards the adoption of contactless sensors, driven by advancements in technology and the increasing demand for maintenance-free solutions. However, contact sensors continue to hold a significant share of the market due to their proven reliability and cost-effectiveness. As industries continue to evolve and prioritize efficiency and reliability, the demand for both contact and contactless water in oil sensors is expected to rise. Manufacturers are focusing on developing innovative solutions that combine the strengths of both sensor types, offering enhanced performance and versatility. The integration of smart technologies and IoT capabilities is also becoming a key trend in the market, enabling real-time monitoring and data analysis for improved decision-making and maintenance planning. Overall, the global market for water in oil sensors is poised for growth, driven by the increasing need for efficient monitoring solutions and the continuous advancements in sensor technology.

Engine or Oil Systems, Gear Boxes, Hydraulic Systems, Transformers, Cooling/Ventilation Systems, Cylinders, Pumps, Compressors in the Water in Oil Sensor - Global Market:

Water in oil sensors play a vital role in various applications, including engine or oil systems, gearboxes, hydraulic systems, transformers, cooling/ventilation systems, cylinders, pumps, and compressors. In engine or oil systems, these sensors are essential for monitoring the oil's condition and ensuring optimal performance. Water contamination in engine oil can lead to reduced lubrication, increased wear and tear, and potential engine failure. By detecting water content early, these sensors help in preventing costly repairs and downtime. In gearboxes, water in oil sensors are used to maintain the quality of the lubricant, which is crucial for the smooth operation of gears and bearings. Water contamination can cause corrosion and pitting, leading to premature failure of gearbox components. Hydraulic systems also benefit from water in oil sensors, as water can cause hydraulic fluid degradation, leading to reduced system efficiency and potential damage to hydraulic components. In transformers, water in oil sensors are used to monitor the insulating oil's condition, which is critical for the transformer's performance and longevity. Water contamination can reduce the oil's dielectric strength, increasing the risk of electrical failures. Cooling and ventilation systems also rely on these sensors to ensure the proper functioning of lubricants and coolants, preventing overheating and system failures. In cylinders, pumps, and compressors, water in oil sensors help in maintaining the quality of lubricants, ensuring efficient operation and reducing the risk of damage due to water contamination. Overall, the use of water in oil sensors in these applications helps in improving system reliability, reducing maintenance costs, and extending the lifespan of equipment. As industries continue to prioritize operational efficiency and reliability, the demand for water in oil sensors in these applications is expected to grow.

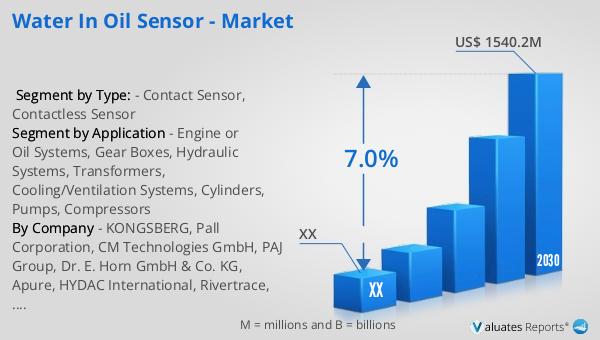

Water in Oil Sensor - Global Market Outlook:

The global market for water in oil sensors was valued at approximately $9,811 million in 2023. This market is projected to undergo significant changes, with an anticipated adjustment leading to a market size of around $1,540.2 million by 2030. This shift represents a compound annual growth rate (CAGR) of 7.0% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient monitoring solutions across various industries. The market's expansion is driven by the need for advanced technologies that can accurately detect water contamination in oil, ensuring the optimal performance and longevity of machinery and equipment. As industries continue to evolve and prioritize maintenance and operational efficiency, the adoption of water in oil sensors is expected to rise. The market's growth is also supported by technological advancements and the integration of smart technologies, enabling real-time monitoring and data analysis for improved decision-making and maintenance planning. Overall, the global market for water in oil sensors is poised for growth, driven by the increasing need for efficient monitoring solutions and the continuous advancements in sensor technology.

| Report Metric | Details |

| Report Name | Water in Oil Sensor - Market |

| Forecasted market size in 2030 | US$ 1540.2 million |

| CAGR | 7.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | KONGSBERG, Pall Corporation, CM Technologies GmbH, PAJ Group, Dr. E. Horn GmbH & Co. KG, Apure, HYDAC International, Rivertrace, Hach, Vaisala, TX Marine Hamburg, Eaton, Yateks, Bühler Technologies GmbH, Des-Case, Eriever, VOLKE, IST AG, Jetec, Inzoc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |