What is Benzoxazine Thermosetting Resin - Global Market?

Benzoxazine thermosetting resin is a unique type of polymer that has gained significant attention in the global market due to its exceptional properties. These resins are known for their high thermal stability, low water absorption, and excellent mechanical properties, making them ideal for various industrial applications. Unlike traditional thermosetting resins, benzoxazine resins do not release volatile by-products during curing, which makes them environmentally friendly and safer to use. The global market for benzoxazine thermosetting resin is driven by the increasing demand in industries such as aerospace, electronics, automotive, and medical sectors. These resins offer superior performance compared to conventional materials, which is why they are increasingly being adopted in high-performance applications. The market is characterized by continuous research and development efforts to enhance the properties of benzoxazine resins and expand their application scope. As industries seek materials that offer better performance and sustainability, benzoxazine thermosetting resins are poised to play a crucial role in meeting these demands. The market's growth is also supported by advancements in manufacturing technologies that enable the production of high-quality benzoxazine resins at competitive costs.

Bisphenol-A Based Benzoxazine, Bisphenol-F Based Benzoxazine, Thiodiphenol Based Benzoxazine, Dicyclopentadiene Based Benzoxazine in the Benzoxazine Thermosetting Resin - Global Market:

Bisphenol-A based benzoxazine is one of the most widely used types of benzoxazine thermosetting resins. It is known for its excellent thermal and mechanical properties, making it suitable for high-performance applications. This type of benzoxazine resin is often used in the aerospace and electronics industries due to its ability to withstand extreme temperatures and harsh environments. Bisphenol-F based benzoxazine, on the other hand, offers improved chemical resistance and lower viscosity compared to its Bisphenol-A counterpart. This makes it ideal for applications where chemical exposure is a concern, such as in the automotive and industrial sectors. Thiodiphenol based benzoxazine is another variant that is gaining popularity due to its unique properties. It offers enhanced flame retardancy and lower smoke emission, which are critical factors in applications like construction and transportation. Dicyclopentadiene based benzoxazine is known for its excellent toughness and impact resistance. This makes it suitable for applications that require materials to withstand mechanical stress and impact, such as in the manufacturing of sports equipment and protective gear. Each of these benzoxazine variants has its own set of advantages and is chosen based on the specific requirements of the application. The global market for benzoxazine thermosetting resins is witnessing a growing demand for these specialized variants as industries seek materials that offer a combination of performance, safety, and sustainability. Manufacturers are investing in research and development to further enhance the properties of these resins and expand their application scope. The versatility of benzoxazine resins, combined with their superior performance characteristics, makes them an attractive choice for a wide range of industries. As the demand for high-performance materials continues to rise, the market for benzoxazine thermosetting resins is expected to grow, driven by the increasing adoption of these advanced materials in various applications.

Aerospace, Electronics & Semiconductors, Automotive, Medical, Others in the Benzoxazine Thermosetting Resin - Global Market:

Benzoxazine thermosetting resins are increasingly being used in a variety of industries due to their exceptional properties. In the aerospace sector, these resins are valued for their high thermal stability and mechanical strength, which are essential for components that must withstand extreme conditions. They are used in the manufacturing of aircraft parts, where weight reduction and durability are critical. In the electronics and semiconductors industry, benzoxazine resins are used for their excellent dielectric properties and low moisture absorption. These characteristics make them ideal for use in printed circuit boards and other electronic components that require reliable performance in demanding environments. The automotive industry also benefits from the use of benzoxazine resins, particularly in the production of lightweight and durable components. These resins help improve fuel efficiency and reduce emissions by enabling the production of lighter vehicles without compromising on strength and safety. In the medical field, benzoxazine resins are used in the manufacturing of medical devices and equipment due to their biocompatibility and resistance to sterilization processes. This ensures that medical products are safe for use and can withstand the rigorous cleaning and sterilization procedures required in healthcare settings. Beyond these industries, benzoxazine resins are also used in various other applications, such as in the construction and marine sectors, where their flame retardancy and resistance to harsh environmental conditions are highly valued. The versatility and superior performance of benzoxazine thermosetting resins make them an attractive choice for a wide range of applications, driving their demand in the global market. As industries continue to seek materials that offer a balance of performance, safety, and sustainability, benzoxazine resins are well-positioned to meet these needs and contribute to the advancement of various sectors.

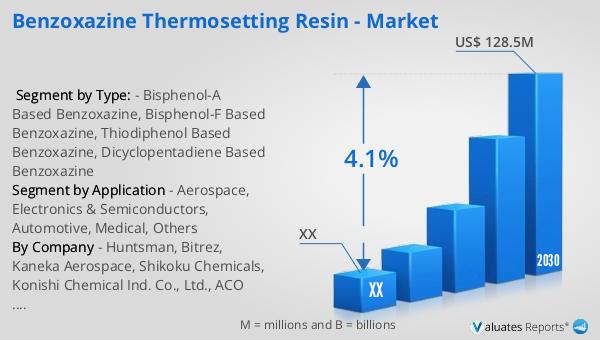

Benzoxazine Thermosetting Resin - Global Market Outlook:

The global market for benzoxazine thermosetting resin was valued at approximately $83 million in 2023. It is projected to grow to a revised size of $128.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.1% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-performance materials across various industries, including aerospace, electronics, automotive, and medical sectors. The unique properties of benzoxazine resins, such as high thermal stability, low water absorption, and excellent mechanical strength, make them an attractive choice for applications that require reliable and durable materials. As industries continue to prioritize sustainability and performance, the demand for benzoxazine resins is expected to rise. The market's growth is also supported by advancements in manufacturing technologies that enable the production of high-quality benzoxazine resins at competitive costs. This allows manufacturers to meet the growing demand for these advanced materials while maintaining cost-effectiveness. As a result, the benzoxazine thermosetting resin market is poised for significant growth in the coming years, driven by the increasing adoption of these materials in various high-performance applications.

| Report Metric | Details |

| Report Name | Benzoxazine Thermosetting Resin - Market |

| Forecasted market size in 2030 | US$ 128.5 million |

| CAGR | 4.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Huntsman, Bitrez, Kaneka Aerospace, Shikoku Chemicals, Konishi Chemical Ind. Co., Ltd., ACO Pharm Co., LTD, Gurit Holding AG, Japan Material Technologies Corporation, ABR Organics Limited. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |