What is Iron Ore Powder - Global Market?

Iron ore powder is a finely ground form of iron ore, which is a crucial raw material in various industries worldwide. This powder is derived from iron ore, a naturally occurring mineral composed primarily of iron oxides. The global market for iron ore powder is vast and dynamic, driven by its essential role in the production of steel, which is a fundamental material for construction, manufacturing, and numerous other sectors. The demand for iron ore powder is closely linked to the global economic landscape, as it is a key component in infrastructure development and industrialization. The market is influenced by factors such as technological advancements in mining and processing, fluctuations in iron ore prices, and the overall demand for steel. Additionally, environmental regulations and sustainability initiatives are shaping the market, as industries seek to reduce their carbon footprint and adopt more eco-friendly practices. The global market for iron ore powder is characterized by a diverse range of players, from large multinational corporations to smaller regional producers, each contributing to the supply chain that meets the ever-growing demand for this vital resource.

Hematite Powder, Magnetite Powder in the Iron Ore Powder - Global Market:

Hematite powder and magnetite powder are two significant forms of iron ore powder, each with distinct characteristics and applications in the global market. Hematite powder is derived from hematite ore, which is one of the most abundant and economically important iron ores. It is known for its high iron content, typically around 70%, making it a preferred choice for steel production. Hematite powder is used extensively in the steel industry due to its efficiency in the blast furnace process, where it is reduced to produce molten iron. This powder is also utilized in various other applications, such as in the production of pigments, heavy media separation, and as a radiation shielding material. The global market for hematite powder is driven by the demand for high-quality steel and the need for efficient and sustainable production processes. On the other hand, magnetite powder is derived from magnetite ore, which is another important source of iron. Magnetite is known for its magnetic properties and lower iron content compared to hematite, typically around 60-70%. Despite its lower iron content, magnetite powder is highly valued for its use in the production of high-density concrete, coal washing, and as a catalyst in chemical reactions. The magnetic properties of magnetite make it an essential component in various industrial applications, including magnetic separation processes and the production of magnetic recording media. The global market for magnetite powder is influenced by its diverse applications and the growing demand for specialized materials in various industries. Both hematite and magnetite powders are integral to the global iron ore powder market, each offering unique benefits and catering to different industrial needs. The market dynamics for these powders are shaped by factors such as technological advancements, environmental regulations, and the overall demand for iron and steel products. As industries continue to evolve and seek more efficient and sustainable production methods, the demand for high-quality iron ore powders like hematite and magnetite is expected to grow, driving innovation and development in the global market.

Steel Industry, Oil Refining Industry, Appliance Industry, Automobile Industry, Others in the Iron Ore Powder - Global Market:

Iron ore powder plays a crucial role in various industries, with its applications spanning the steel industry, oil refining industry, appliance industry, automobile industry, and others. In the steel industry, iron ore powder is a fundamental raw material used in the production of steel, which is essential for construction, infrastructure development, and manufacturing. The powder is used in blast furnaces, where it is reduced to produce molten iron, which is then converted into steel. The quality and efficiency of the steel production process are significantly influenced by the properties of the iron ore powder used, making it a critical component in the industry. In the oil refining industry, iron ore powder is used as a catalyst in various chemical reactions, particularly in the desulfurization process. The powder helps in removing sulfur compounds from crude oil, improving the quality of the refined products and reducing environmental pollution. The appliance industry also benefits from the use of iron ore powder, as it is used in the production of various components and parts for household and industrial appliances. The powder's properties, such as its high density and magnetic characteristics, make it suitable for use in the manufacturing of durable and efficient appliances. In the automobile industry, iron ore powder is used in the production of various automotive components, including engine parts, brake systems, and structural components. The powder's strength and durability make it an ideal material for manufacturing high-performance and long-lasting automotive parts. Additionally, iron ore powder is used in other industries, such as the production of pigments, heavy media separation, and as a radiation shielding material. The versatility and wide range of applications of iron ore powder make it a valuable resource in the global market, driving demand and innovation across various sectors.

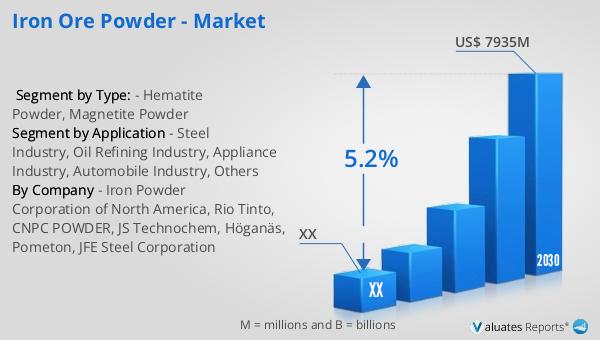

Iron Ore Powder - Global Market Outlook:

The global market for iron ore powder was valued at approximately USD 5,733 million in 2023. Looking ahead, it is anticipated that the market will grow to an adjusted size of around USD 7,935 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.2% over the forecast period from 2024 to 2030. This projected growth is indicative of the increasing demand for iron ore powder across various industries, driven by factors such as urbanization, industrialization, and the ongoing development of infrastructure projects worldwide. The market's expansion is also supported by advancements in mining and processing technologies, which enhance the efficiency and sustainability of iron ore powder production. Additionally, the growing emphasis on reducing carbon emissions and adopting eco-friendly practices in industries is expected to further boost the demand for high-quality iron ore powder. As the global economy continues to evolve, the iron ore powder market is poised to play a vital role in supporting industrial growth and development, making it a key area of focus for stakeholders and investors alike.

| Report Metric | Details |

| Report Name | Iron Ore Powder - Market |

| Forecasted market size in 2030 | US$ 7935 million |

| CAGR | 5.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Iron Powder Corporation of North America, Rio Tinto, CNPC POWDER, JS Technochem, Höganäs, Pometon, JFE Steel Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |