What is OPS Shrink Film - Global Market?

OPS shrink film, or Oriented Polystyrene shrink film, is a type of packaging material that has gained significant traction in the global market due to its versatile applications and cost-effectiveness. This film is primarily used for labeling and packaging purposes, offering a high degree of clarity and gloss, which enhances the visual appeal of packaged products. OPS shrink film is known for its excellent shrinkage properties, which allow it to conform tightly to the contours of various shapes and sizes, making it ideal for packaging irregularly shaped items. Additionally, it provides a protective barrier against moisture and contaminants, ensuring the integrity and freshness of the packaged goods. The global market for OPS shrink film is driven by its widespread use in industries such as food and beverage, pharmaceuticals, and consumer goods, where it is employed to wrap bottles, cans, jars, and trays. Its ability to provide a tamper-evident seal further adds to its appeal, particularly in sectors where product safety and integrity are paramount. As consumer demand for visually appealing and secure packaging continues to rise, the OPS shrink film market is poised for sustained growth.

40μm, 50μm, Other in the OPS Shrink Film - Global Market:

When discussing OPS shrink film in terms of thickness, the market is segmented into categories such as 40μm, 50μm, and other thicknesses. Each thickness offers distinct advantages and is chosen based on specific application requirements. The 40μm OPS shrink film is often favored for its lightweight properties, making it an economical choice for packaging applications where cost efficiency is a priority. This thinner film is particularly suitable for products that do not require heavy-duty protection but still benefit from the aesthetic and protective qualities of shrink film. Its reduced material usage also aligns with sustainability goals, as it minimizes waste and resource consumption. On the other hand, the 50μm OPS shrink film provides a more robust option, offering enhanced durability and strength. This thickness is ideal for packaging heavier or more fragile items that require additional support and protection during transportation and handling. The increased thickness also contributes to a more substantial feel, which can be perceived as a premium packaging solution by consumers. Beyond these standard thicknesses, the market also includes other variations tailored to specific needs, such as ultra-thin films for delicate items or thicker films for industrial applications. These diverse options allow manufacturers to select the most appropriate film thickness based on factors such as product weight, shape, and the level of protection required. The choice of thickness can also influence the shrinkage rate and clarity of the film, impacting the overall presentation and functionality of the packaging. As a result, manufacturers often conduct thorough testing and evaluation to determine the optimal film thickness for their specific products and market demands. The availability of multiple thickness options in the OPS shrink film market underscores its adaptability and versatility, catering to a wide range of packaging needs across various industries. This flexibility is a key driver of the market's growth, as it enables businesses to tailor their packaging solutions to meet evolving consumer preferences and regulatory requirements. Furthermore, advancements in manufacturing technology continue to enhance the performance characteristics of OPS shrink films, expanding their potential applications and reinforcing their position as a preferred packaging material in the global market.

Food, Beverage, Commodity, Other in the OPS Shrink Film - Global Market:

OPS shrink film finds extensive usage across various sectors, including food, beverage, commodity, and other industries, due to its versatile properties and benefits. In the food industry, OPS shrink film is widely used for packaging a variety of products, ranging from fresh produce to processed foods. Its ability to conform tightly to the shape of the product ensures a secure and attractive package, which is crucial for maintaining freshness and extending shelf life. The film's clarity and gloss enhance the visual appeal of food products, making them more enticing to consumers. Additionally, OPS shrink film provides a tamper-evident seal, which is essential for ensuring food safety and consumer trust. In the beverage industry, OPS shrink film is commonly used for labeling and packaging bottles and cans. Its excellent shrinkage properties allow it to fit snugly around containers of various shapes and sizes, providing a seamless and professional appearance. This is particularly important for branding and marketing purposes, as the packaging serves as a key touchpoint for consumer engagement. The film's moisture resistance also protects the integrity of the beverage, preventing contamination and spoilage. In the commodity sector, OPS shrink film is employed for packaging a wide range of consumer goods, from household items to personal care products. Its versatility and adaptability make it suitable for wrapping products of different shapes and sizes, ensuring a secure and protective package. The film's durability and strength provide added protection during transportation and handling, reducing the risk of damage and loss. Beyond these primary sectors, OPS shrink film is also used in other industries, such as pharmaceuticals and electronics, where it serves as a protective barrier against environmental factors and tampering. Its ability to provide a clear and attractive package makes it an ideal choice for showcasing products and enhancing their marketability. As consumer demand for high-quality and visually appealing packaging continues to grow, the usage of OPS shrink film is expected to expand across various sectors, driving further innovation and development in the market.

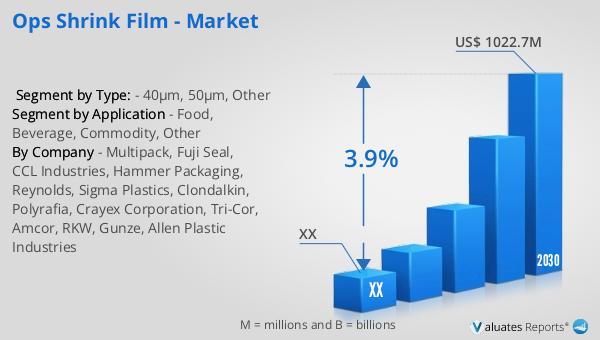

OPS Shrink Film - Global Market Outlook:

In 2023, the global OPS shrink film market was valued at approximately $764.6 million, with projections indicating a growth to around $1,022.7 million by 2030. This anticipated growth reflects a compound annual growth rate (CAGR) of 3.9% from 2024 to 2030. The increasing demand for OPS shrink film is largely attributed to its extensive applications in the food and beverage industry. This versatile packaging material is commonly used for wrapping bottles, cans, jars, and trays of various sizes, providing a secure and visually appealing package. The film's excellent shrinkage properties allow it to conform tightly to the contours of different containers, enhancing the overall presentation and functionality of the packaging. Additionally, OPS shrink film offers a tamper-evident seal, which is crucial for ensuring product safety and consumer confidence. As the food and beverage industry continues to evolve, with a growing emphasis on sustainability and consumer engagement, the demand for OPS shrink film is expected to rise. Its ability to provide a high-quality and cost-effective packaging solution makes it an attractive choice for manufacturers and brands looking to enhance their product offerings and meet changing consumer preferences. The projected growth of the OPS shrink film market underscores its importance as a key component of modern packaging strategies, driving innovation and development in the industry.

| Report Metric | Details |

| Report Name | OPS Shrink Film - Market |

| Forecasted market size in 2030 | US$ 1022.7 million |

| CAGR | 3.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Multipack, Fuji Seal, CCL Industries, Hammer Packaging, Reynolds, Sigma Plastics, Clondalkin, Polyrafia, Crayex Corporation, Tri-Cor, Amcor, RKW, Gunze, Allen Plastic Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |