What is High-performance Magnetorheologial(MR) Fluid - Global Market?

High-performance Magnetorheological (MR) Fluid is a fascinating material that has garnered significant attention in the global market due to its unique properties and versatile applications. Essentially, MR fluid is a type of smart fluid that changes its viscosity in response to a magnetic field. This means that when a magnetic field is applied, the fluid can transform from a liquid to a semi-solid state almost instantaneously. This remarkable ability makes MR fluids highly valuable in various industries, as they can be used to create adaptive systems that respond dynamically to changing conditions. The global market for high-performance MR fluids is driven by the demand for advanced materials that can enhance the performance and efficiency of products across sectors such as automotive, aerospace, and robotics. As industries continue to seek innovative solutions to improve functionality and reduce energy consumption, the role of MR fluids is expected to expand, offering new opportunities for growth and development. The adaptability and responsiveness of MR fluids make them a key component in the development of next-generation technologies, positioning them as a critical element in the future of smart materials.

Silicon Oil, Mineral Oil, Synthetic Hydrocarbon Oil, Paraffin Oil, Hydraulic Oil, Water, Others in the High-performance Magnetorheologial(MR) Fluid - Global Market:

In the realm of high-performance Magnetorheological (MR) fluids, various base oils play a crucial role in determining the fluid's properties and performance. Silicon oil is one of the most commonly used base oils in MR fluids due to its excellent thermal stability and low viscosity. This makes it ideal for applications where temperature fluctuations are a concern, as it can maintain its performance across a wide range of temperatures. Mineral oil, on the other hand, is valued for its cost-effectiveness and availability. It provides a good balance of performance and affordability, making it a popular choice for many industrial applications. Synthetic hydrocarbon oil offers superior lubrication properties and is often used in high-performance applications where reduced friction and wear are critical. Paraffin oil, known for its high purity and stability, is another option that is often used in MR fluids for applications requiring consistent performance over time. Hydraulic oil is specifically designed for use in hydraulic systems and is chosen for its ability to provide smooth and efficient operation in such environments. Water, while not a traditional oil, is sometimes used in MR fluids for applications where environmental concerns are paramount, as it is non-toxic and environmentally friendly. Each of these base oils brings unique characteristics to MR fluids, allowing them to be tailored to specific applications and requirements. The choice of base oil can significantly impact the performance, cost, and environmental impact of MR fluids, making it a critical consideration in their development and use. As the global market for high-performance MR fluids continues to grow, the demand for diverse and specialized base oils is expected to increase, driving innovation and development in this field. The versatility and adaptability of MR fluids, combined with the wide range of available base oils, make them a powerful tool for engineers and designers looking to create advanced systems that can respond dynamically to changing conditions.

Automotive, Aerospace, Building & Construction, Military & Defense, Optics, Electrical & Electronics, Medical, Robotics, Others in the High-performance Magnetorheologial(MR) Fluid - Global Market:

High-performance Magnetorheological (MR) fluids have found a wide range of applications across various industries, thanks to their unique ability to change viscosity in response to a magnetic field. In the automotive industry, MR fluids are used in suspension systems to provide adaptive damping, improving ride comfort and handling by adjusting the suspension stiffness in real-time based on road conditions. This technology enhances vehicle performance and safety, making it a popular choice for high-end and performance vehicles. In the aerospace sector, MR fluids are used in vibration control systems to reduce noise and improve the stability of aircraft components. Their ability to provide precise and rapid adjustments makes them ideal for maintaining the structural integrity of aircraft under varying conditions. In the building and construction industry, MR fluids are employed in seismic dampers to protect structures from earthquake damage by absorbing and dissipating energy. This application is particularly valuable in regions prone to seismic activity, where building safety is a top priority. The military and defense sector utilizes MR fluids in various applications, including adaptive armor systems and recoil management in firearms, where their ability to provide rapid response and adaptability is crucial. In the field of optics, MR fluids are used in adaptive lenses and mirrors to improve image quality and focus by adjusting the optical properties in real-time. The electrical and electronics industry benefits from MR fluids in the development of haptic devices, where they provide tactile feedback by changing the resistance of the fluid in response to user input. In the medical field, MR fluids are used in prosthetics and rehabilitation devices to provide adaptive support and resistance, enhancing patient comfort and mobility. Robotics is another area where MR fluids are making a significant impact, as they enable the development of soft and flexible actuators that can mimic human muscle movements. This technology is particularly valuable in the creation of advanced robotic systems that require precise and adaptive control. The versatility and adaptability of MR fluids make them a valuable tool in a wide range of applications, driving innovation and development across multiple industries. As the global market for high-performance MR fluids continues to expand, their role in shaping the future of technology and engineering is expected to grow, offering new opportunities for advancement and improvement.

High-performance Magnetorheologial(MR) Fluid - Global Market Outlook:

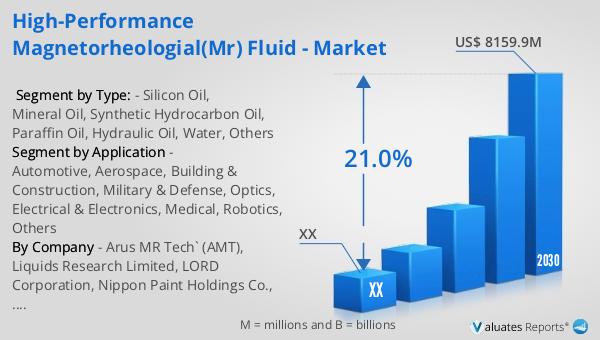

The market outlook for high-performance Magnetorheological (MR) fluids is promising, with significant growth anticipated in the coming years. In 2023, the market was valued at approximately US$ 1,500 million, reflecting the increasing demand for advanced materials that offer unique properties and capabilities. Looking ahead, the market is projected to reach a size of US$ 8,159.9 million by 2030, driven by a compound annual growth rate (CAGR) of 21.0% during the forecast period from 2024 to 2030. This substantial growth is indicative of the expanding applications and adoption of MR fluids across various industries, as companies seek innovative solutions to enhance performance and efficiency. The North American market, in particular, is expected to play a significant role in this growth, as the region is home to a robust industrial base and a strong focus on technological advancement. The increasing demand for smart materials that can adapt to changing conditions is driving the development and use of MR fluids, positioning them as a key component in the future of engineering and design. As industries continue to evolve and seek new ways to improve functionality and reduce energy consumption, the role of MR fluids is expected to expand, offering new opportunities for growth and development. The adaptability and responsiveness of MR fluids make them a critical element in the development of next-generation technologies, positioning them as a vital component in the future of smart materials.

| Report Metric | Details |

| Report Name | High-performance Magnetorheologial(MR) Fluid - Market |

| Forecasted market size in 2030 | US$ 8159.9 million |

| CAGR | 21.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Arus MR Tech` (AMT), Liquids Research Limited, LORD Corporation, Nippon Paint Holdings Co., Ltd., Akebono Brake Industry Co., Ltd., Anton Paar GmbH, Arus MR Tech Pvt Ltd., CK Materials Lab Co., Ltd., Industrial Metal Powders (I) Pvt Ltd., Loniqa Technologies B.V., Kurimoto, Ltd., MRF Engineering, QED Technologies International, Inc., Bohai New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |