What is Hydrodemetallization (HDM) Catalyst - Global Market?

Hydrodemetallization (HDM) catalysts play a crucial role in the refining industry by removing metal impurities from heavy crude oil and other petroleum products. These catalysts are essential in the hydroprocessing of crude oil, where they help in the conversion of heavy fractions into lighter, more valuable products. The global market for HDM catalysts is driven by the increasing demand for cleaner fuels and the need to process heavier crude oils, which contain higher levels of metal contaminants. These catalysts are typically composed of active metals like nickel (Ni) and molybdenum (Mo) supported on a carrier material such as alumina. The process of hydrodemetallization involves the use of hydrogen to remove metal impurities, which can poison other catalysts and reduce the efficiency of refining processes. As environmental regulations become stricter and the quality of crude oil declines, the demand for effective HDM catalysts is expected to grow. This market is characterized by technological advancements aimed at improving catalyst performance and longevity, as well as efforts to reduce operational costs. Companies in this sector are investing in research and development to create more efficient catalysts that can operate under harsher conditions and deliver better results.

Ni, Mo-Ni in the Hydrodemetallization (HDM) Catalyst - Global Market:

Nickel (Ni) and molybdenum (Mo) are two of the most commonly used metals in hydrodemetallization (HDM) catalysts, and they play a significant role in the global market for these products. Ni-based catalysts are particularly effective in removing nickel and vanadium impurities from heavy crude oils. These metals are often present in high concentrations in heavier crude oils, which are increasingly being processed as lighter, sweeter crudes become less available. Ni-based catalysts are known for their ability to withstand high temperatures and pressures, making them suitable for the harsh conditions of hydroprocessing. Molybdenum, on the other hand, is often used in combination with nickel to enhance the overall performance of the catalyst. Mo-Ni catalysts are highly effective in breaking down complex hydrocarbons and removing metal impurities, which can otherwise lead to fouling and deactivation of other catalysts in the refining process. The combination of Ni and Mo provides a synergistic effect that enhances the catalytic activity and stability, allowing for more efficient processing of heavy crude oils. The global market for Ni and Mo-Ni based HDM catalysts is driven by the need for more efficient and cost-effective solutions for processing heavy crude oils. As the quality of available crude oil continues to decline, refineries are increasingly turning to these catalysts to improve their operational efficiency and meet environmental regulations. The demand for Ni and Mo-Ni based catalysts is also influenced by the growing emphasis on sustainability and the need to reduce the environmental impact of refining processes. Companies in this market are focusing on developing catalysts that offer improved performance, longer lifespans, and reduced environmental impact. This includes efforts to enhance the selectivity and activity of the catalysts, as well as to reduce the amount of waste generated during the refining process. The global market for Ni and Mo-Ni based HDM catalysts is expected to continue growing as refineries seek to optimize their operations and meet the challenges posed by declining crude oil quality and increasing environmental regulations.

VGO, Residue, Other in the Hydrodemetallization (HDM) Catalyst - Global Market:

Hydrodemetallization (HDM) catalysts are used in various applications within the refining industry, including the processing of vacuum gas oil (VGO), residue, and other heavy fractions. In the case of VGO, HDM catalysts are used to remove metal impurities that can poison other catalysts used in subsequent refining processes. VGO is a key feedstock for the production of high-quality fuels and lubricants, and the presence of metal impurities can significantly impact the efficiency and effectiveness of these processes. By using HDM catalysts, refineries can improve the quality of VGO and enhance the overall yield of valuable products. In the processing of residue, HDM catalysts are used to break down complex hydrocarbons and remove metal impurities that can cause fouling and deactivation of other catalysts. Residue is the heaviest fraction of crude oil and contains the highest concentration of metal impurities. The use of HDM catalysts in residue processing helps to improve the quality of the final products and reduce the environmental impact of refining operations. Other applications of HDM catalysts include the processing of heavy crude oils and bitumen, where they are used to remove metal impurities and improve the quality of the final products. The global market for HDM catalysts in these applications is driven by the increasing demand for cleaner fuels and the need to process heavier crude oils. As environmental regulations become stricter and the quality of crude oil declines, the demand for effective HDM catalysts is expected to grow. Companies in this market are investing in research and development to create more efficient catalysts that can operate under harsher conditions and deliver better results. This includes efforts to enhance the selectivity and activity of the catalysts, as well as to reduce the amount of waste generated during the refining process. The global market for HDM catalysts in these applications is expected to continue growing as refineries seek to optimize their operations and meet the challenges posed by declining crude oil quality and increasing environmental regulations.

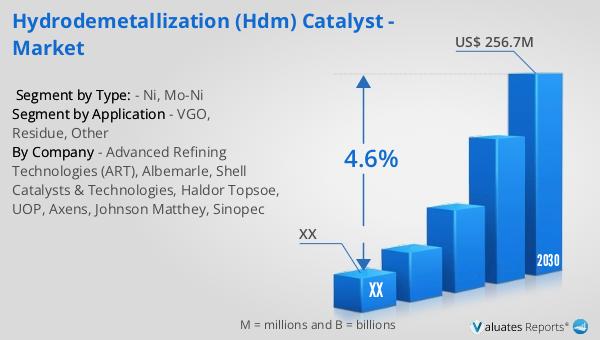

Hydrodemetallization (HDM) Catalyst - Global Market Outlook:

In 2023, the global market for Hydrodemetallization (HDM) catalysts was valued at approximately $187 million. This market is projected to experience growth, reaching an estimated size of $256.7 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 4.6% over the forecast period from 2024 to 2030. The increasing demand for HDM catalysts is driven by the need for more efficient and cost-effective solutions for processing heavy crude oils, as well as the growing emphasis on sustainability and environmental regulations. As refineries seek to optimize their operations and meet the challenges posed by declining crude oil quality, the demand for effective HDM catalysts is expected to grow. Companies in this market are focusing on developing catalysts that offer improved performance, longer lifespans, and reduced environmental impact. This includes efforts to enhance the selectivity and activity of the catalysts, as well as to reduce the amount of waste generated during the refining process. The global market for HDM catalysts is expected to continue growing as refineries seek to optimize their operations and meet the challenges posed by declining crude oil quality and increasing environmental regulations.

| Report Metric | Details |

| Report Name | Hydrodemetallization (HDM) Catalyst - Market |

| Forecasted market size in 2030 | US$ 256.7 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Advanced Refining Technologies (ART), Albemarle, Shell Catalysts & Technologies, Haldor Topsoe, UOP, Axens, Johnson Matthey, Sinopec |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |