What is High-accuracy Thermo-compression (TC) Bonder - Global Market?

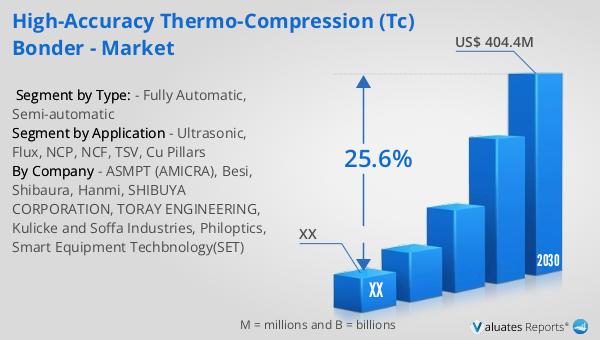

High-accuracy Thermo-compression (TC) Bonder is a specialized technology used in the semiconductor industry for precise bonding applications. This technology is crucial for creating reliable connections between different components in electronic devices. The global market for High-accuracy TC Bonder is experiencing significant growth due to the increasing demand for advanced electronic devices and the miniaturization of components. In 2023, the market was valued at approximately US$ 82 million, and it is projected to expand to around US$ 404.4 million by 2030, reflecting a compound annual growth rate (CAGR) of 25.6% from 2024 to 2030. This growth is driven by the need for high-precision bonding solutions in various applications, including smartphones, tablets, and other consumer electronics, as well as in automotive and industrial sectors. The technology's ability to provide accurate and reliable bonding solutions makes it an essential tool for manufacturers looking to enhance the performance and reliability of their products. As the demand for more sophisticated electronic devices continues to rise, the High-accuracy TC Bonder market is expected to play a pivotal role in meeting these technological advancements.

Fully Automatic, Semi-automatic in the High-accuracy Thermo-compression (TC) Bonder - Global Market:

The High-accuracy Thermo-compression (TC) Bonder market can be segmented into fully automatic and semi-automatic systems, each catering to different needs and preferences of manufacturers. Fully automatic TC Bonders are designed for high-volume production environments where speed and precision are paramount. These systems are equipped with advanced automation features that allow for continuous operation with minimal human intervention, making them ideal for large-scale manufacturing processes. They offer high throughput and consistent quality, which are essential for meeting the demands of mass production in industries such as consumer electronics and automotive. On the other hand, semi-automatic TC Bonders provide a balance between automation and manual control, offering flexibility for smaller production runs or specialized applications. These systems are often used in research and development settings or for niche markets where customization and adaptability are required. Semi-automatic TC Bonders allow operators to have more control over the bonding process, enabling them to make adjustments as needed to achieve the desired results. Both fully automatic and semi-automatic TC Bonders play a crucial role in the global market, catering to the diverse needs of manufacturers across various industries. The choice between the two depends on factors such as production volume, budget, and specific application requirements. As the demand for high-precision bonding solutions continues to grow, manufacturers are increasingly investing in these technologies to enhance their production capabilities and maintain a competitive edge in the market. The global market for High-accuracy TC Bonders is characterized by rapid technological advancements and increasing competition among key players. Manufacturers are continuously innovating to develop more efficient and cost-effective bonding solutions that meet the evolving needs of the industry. This has led to the introduction of new features and capabilities in both fully automatic and semi-automatic TC Bonders, such as improved accuracy, faster processing speeds, and enhanced user interfaces. These advancements are driving the adoption of TC Bonders across various sectors, including consumer electronics, automotive, aerospace, and healthcare. In the consumer electronics industry, the miniaturization of devices and the increasing complexity of electronic components are fueling the demand for high-precision bonding solutions. Fully automatic TC Bonders are particularly well-suited for this sector, as they can handle large volumes of production while maintaining consistent quality and precision. In the automotive industry, the growing trend towards electric and autonomous vehicles is creating new opportunities for TC Bonder manufacturers. These vehicles require advanced electronic systems that rely on precise bonding techniques to ensure reliability and performance. Semi-automatic TC Bonders are often used in this sector for specialized applications, such as bonding sensors and other critical components. The aerospace industry also presents significant growth opportunities for the TC Bonder market, as the demand for lightweight and high-performance materials continues to rise. In this sector, both fully automatic and semi-automatic TC Bonders are used to bond components in aircraft and spacecraft, where precision and reliability are of utmost importance. The healthcare industry is another key market for TC Bonders, as medical devices and equipment become increasingly sophisticated and require precise bonding solutions. Overall, the global market for High-accuracy Thermo-compression (TC) Bonders is poised for significant growth in the coming years, driven by the increasing demand for advanced electronic devices and the need for high-precision bonding solutions across various industries. As manufacturers continue to invest in these technologies, the market is expected to witness further innovation and expansion, offering new opportunities for growth and development.

Ultrasonic, Flux, NCP, NCF, TSV, Cu Pillars in the High-accuracy Thermo-compression (TC) Bonder - Global Market:

High-accuracy Thermo-compression (TC) Bonders are utilized in a variety of applications, each requiring precise bonding techniques to ensure optimal performance and reliability. In the field of ultrasonic bonding, TC Bonders are used to create strong and durable connections between components by applying heat and pressure. This method is particularly useful in applications where traditional soldering techniques may not be suitable, such as in the assembly of delicate or heat-sensitive components. The use of ultrasonic bonding in conjunction with TC Bonders allows manufacturers to achieve high-quality bonds with minimal thermal impact on the surrounding materials. Flux bonding is another area where High-accuracy TC Bonders are employed. This technique involves the use of a flux material to facilitate the bonding process by removing oxides and contaminants from the surfaces being joined. TC Bonders provide the precise temperature and pressure control needed to ensure that the flux material is activated effectively, resulting in strong and reliable bonds. This method is commonly used in the assembly of electronic components, where clean and secure connections are essential for optimal performance. Non-conductive paste (NCP) and non-conductive film (NCF) bonding are also important applications for High-accuracy TC Bonders. These techniques involve the use of non-conductive materials to bond components without creating electrical connections. TC Bonders offer the precise control needed to apply these materials accurately, ensuring that the bonds are strong and reliable without interfering with the electrical properties of the components. NCP and NCF bonding are commonly used in the assembly of semiconductor devices, where maintaining electrical isolation between components is critical. Through-silicon via (TSV) bonding is another key application for High-accuracy TC Bonders. TSV technology involves creating vertical electrical connections through silicon wafers, allowing for the integration of multiple layers of electronic components. TC Bonders provide the precision and control needed to create these connections accurately, ensuring that the TSVs are properly aligned and bonded. This technology is essential for the development of advanced semiconductor devices, such as 3D integrated circuits, which require high-density interconnections. Copper (Cu) pillar bonding is a final area where High-accuracy TC Bonders are used. This technique involves the use of copper pillars to create electrical connections between components. TC Bonders offer the precise temperature and pressure control needed to bond these pillars securely, ensuring that the connections are strong and reliable. Cu pillar bonding is commonly used in the assembly of advanced semiconductor devices, where high-density interconnections are required to achieve optimal performance. Overall, High-accuracy Thermo-compression (TC) Bonders play a crucial role in a wide range of applications, providing the precision and control needed to create strong and reliable bonds between components. As the demand for advanced electronic devices continues to grow, the use of TC Bonders in these applications is expected to increase, driving further innovation and development in the field.

High-accuracy Thermo-compression (TC) Bonder - Global Market Outlook:

The global market for High-accuracy Thermo-compression (TC) Bonders was valued at approximately US$ 82 million in 2023, and it is anticipated to grow significantly over the coming years. By 2030, the market is projected to reach a size of around US$ 404.4 million, reflecting a compound annual growth rate (CAGR) of 25.6% during the forecast period from 2024 to 2030. This impressive growth trajectory underscores the increasing demand for high-precision bonding solutions across various industries, including consumer electronics, automotive, aerospace, and healthcare. The rapid expansion of the market can be attributed to several factors, including the miniaturization of electronic devices, the growing complexity of electronic components, and the need for reliable and efficient bonding techniques. As manufacturers strive to meet the demands of these evolving industries, the adoption of High-accuracy TC Bonders is expected to rise, driving further innovation and development in the field. The market's growth is also supported by advancements in technology, which have led to the introduction of new features and capabilities in TC Bonders, such as improved accuracy, faster processing speeds, and enhanced user interfaces. These innovations are enabling manufacturers to enhance their production capabilities and maintain a competitive edge in the market. As the global market for High-accuracy Thermo-compression (TC) Bonders continues to expand, it presents significant opportunities for growth and development, offering manufacturers the tools they need to meet the challenges of an increasingly complex and competitive landscape.

| Report Metric | Details |

| Report Name | High-accuracy Thermo-compression (TC) Bonder - Market |

| Forecasted market size in 2030 | US$ 404.4 million |

| CAGR | 25.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ASMPT (AMICRA), Besi, Shibaura, Hanmi, SHIBUYA CORPORATION, TORAY ENGINEERING, Kulicke and Soffa Industries, Philoptics, Smart Equipment Techbnology(SET) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |