What is Vinyl Coating - Global Market?

Vinyl coating is a versatile and widely used material in various industries due to its protective and aesthetic properties. It involves applying a layer of vinyl, a type of plastic, onto surfaces to enhance durability, resistance to corrosion, and appearance. The global market for vinyl coating is expansive, driven by its application in numerous sectors such as construction, automotive, and marine industries. This market is characterized by continuous innovation and development, as manufacturers strive to improve the performance and environmental sustainability of vinyl coatings. The demand for vinyl coatings is fueled by their ability to provide a cost-effective solution for protecting surfaces against harsh environmental conditions, chemicals, and physical wear. Additionally, vinyl coatings are favored for their ease of application and maintenance, making them a popular choice for both industrial and consumer applications. As industries continue to seek materials that offer longevity and protection, the global market for vinyl coating is expected to grow, adapting to new technological advancements and regulatory requirements. The versatility and effectiveness of vinyl coatings ensure their continued relevance in a wide range of applications, making them a critical component in the global materials market.

Epoxy Vinyl Coating, Vinyl Ester Coating, Other in the Vinyl Coating - Global Market:

Epoxy vinyl coating is a specialized type of vinyl coating that combines the properties of epoxy resins with vinyl polymers. This combination results in a coating that offers superior adhesion, chemical resistance, and durability. Epoxy vinyl coatings are particularly valued in environments where surfaces are exposed to harsh chemicals or extreme conditions, such as in chemical plants or offshore oil rigs. These coatings provide a robust barrier against corrosion and wear, extending the lifespan of the underlying materials. Vinyl ester coatings, on the other hand, are known for their excellent resistance to corrosive chemicals and high temperatures. They are often used in applications where traditional coatings might fail, such as in the lining of storage tanks or pipelines that transport aggressive chemicals. Vinyl ester coatings are also appreciated for their flexibility and ability to withstand thermal cycling, making them suitable for use in environments with fluctuating temperatures. Other types of vinyl coatings include those formulated for specific applications, such as anti-graffiti coatings or coatings designed to enhance the aesthetic appeal of surfaces. These specialized coatings are developed to meet the unique needs of different industries, providing tailored solutions that address specific challenges. The global market for vinyl coatings is diverse, with each type of coating offering distinct advantages that cater to the varied requirements of industrial and commercial applications. As industries continue to evolve and face new challenges, the demand for innovative and effective vinyl coatings is expected to grow, driving further research and development in this field. The versatility and adaptability of vinyl coatings make them an essential component in the global market, providing solutions that enhance the performance and longevity of materials across a wide range of applications.

Construction, Marine, Containers, Steel Structures & Bridges, Offshore Oil Rigs, Chemical Plants, Other in the Vinyl Coating - Global Market:

Vinyl coatings are extensively used in the construction industry to protect and enhance the durability of buildings and infrastructure. They are applied to surfaces such as concrete, metal, and wood to provide a protective barrier against moisture, UV radiation, and physical wear. In the marine industry, vinyl coatings are crucial for protecting vessels from the corrosive effects of saltwater and harsh marine environments. These coatings help extend the lifespan of ships and boats, reducing maintenance costs and improving safety. In the container industry, vinyl coatings are used to protect shipping containers from corrosion and damage during transportation and storage. They provide a durable and weather-resistant finish that helps maintain the integrity of the containers over time. Steel structures and bridges benefit from vinyl coatings as they offer excellent protection against rust and corrosion, ensuring the longevity and safety of these critical infrastructures. Offshore oil rigs, which are exposed to some of the harshest environmental conditions, rely on vinyl coatings to protect their structures from corrosion and wear. These coatings are essential for maintaining the integrity and safety of oil rigs, which are vital for energy production. In chemical plants, vinyl coatings are used to protect equipment and surfaces from corrosive chemicals and high temperatures. They provide a reliable barrier that helps prevent leaks and contamination, ensuring the safe and efficient operation of chemical processes. Other applications of vinyl coatings include their use in automotive, aerospace, and consumer goods industries, where they provide protective and decorative finishes that enhance the performance and appearance of products. The versatility and effectiveness of vinyl coatings make them a valuable asset in a wide range of industries, providing solutions that enhance the durability and longevity of materials and structures.

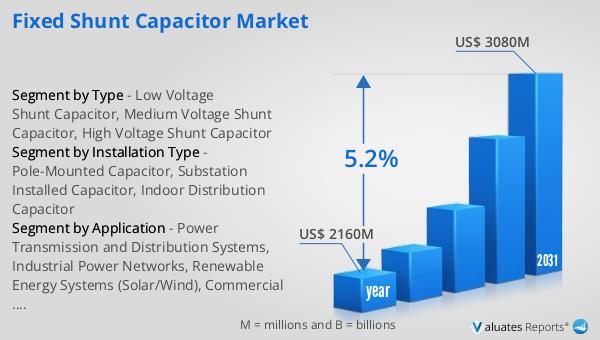

Vinyl Coating - Global Market Outlook:

The global market for vinyl coating was valued at approximately $390.7 million in 2023. This market is projected to grow significantly, reaching an estimated value of $544.4 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2024 to 2030. The increasing demand for durable and protective coatings across various industries is a key driver of this market expansion. Vinyl coatings are favored for their ability to provide cost-effective solutions for protecting surfaces against environmental and chemical damage. As industries continue to seek materials that offer enhanced performance and longevity, the demand for vinyl coatings is anticipated to rise. The market's growth is also supported by ongoing advancements in coating technologies, which aim to improve the performance and environmental sustainability of vinyl coatings. As a result, the global market for vinyl coating is expected to continue its upward trajectory, driven by the need for innovative and effective solutions that meet the evolving demands of industrial and commercial applications.

| Report Metric | Details |

| Report Name | Vinyl Coating - Market |

| Forecasted market size in 2030 | US$ 544.4 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | AkzoNobel, PPG, Beckers, Musashi Paint, Cashew, Sherwin-Williams, Sika, Hempel, Jotun, Henkel, Chugoku Marine Paints, RPM International, Dai Nippon Toryo, NIPSEA Group, Langfang Fengzheng Environmental Protection Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |