What is Rubber Underlayment - Global Market?

Rubber underlayment is a versatile material used primarily in construction and renovation projects to provide sound insulation, cushioning, and moisture protection. It is typically made from recycled rubber, making it an eco-friendly option for builders and homeowners. The global market for rubber underlayment has been growing steadily due to increasing awareness of its benefits, such as noise reduction and enhanced comfort underfoot. This material is commonly used under hardwood, laminate, and tile flooring to absorb sound and reduce impact noise, making it ideal for multi-story buildings and apartments. Additionally, rubber underlayment is resistant to mold and mildew, which extends the lifespan of flooring materials and improves indoor air quality. As urbanization and construction activities continue to rise globally, the demand for rubber underlayment is expected to grow, driven by its durability, sustainability, and performance benefits. The market is also influenced by advancements in manufacturing technologies that enhance the quality and functionality of rubber underlayment products. With increasing consumer preference for sustainable building materials, the rubber underlayment market is poised for further expansion in the coming years.

Nitrile Rubber, Neoprene, SBR in the Rubber Underlayment - Global Market:

Nitrile rubber, neoprene, and styrene-butadiene rubber (SBR) are three types of synthetic rubbers commonly used in the production of rubber underlayment. Each of these materials offers unique properties that make them suitable for specific applications within the global market. Nitrile rubber, known for its excellent resistance to oils, fuels, and chemicals, is often used in environments where exposure to such substances is a concern. This makes it an ideal choice for industrial settings or areas prone to spills and chemical exposure. Its durability and resistance to abrasion also contribute to its popularity in heavy-duty applications. Neoprene, on the other hand, is valued for its flexibility, weather resistance, and thermal insulation properties. It is commonly used in outdoor applications or areas with fluctuating temperatures, as it can withstand harsh weather conditions without degrading. Neoprene's ability to maintain its integrity in extreme temperatures makes it a preferred choice for roofing underlayment, where it provides an additional layer of protection against the elements. Styrene-butadiene rubber (SBR) is widely used in rubber underlayment due to its cost-effectiveness and good mechanical properties. It offers a balance of strength, flexibility, and resistance to wear and tear, making it suitable for a variety of flooring applications. SBR is often used in residential and commercial buildings where cost considerations are important, yet performance cannot be compromised. The global market for rubber underlayment benefits from the diverse properties of these synthetic rubbers, allowing manufacturers to tailor products to meet specific needs and preferences. As the demand for sustainable and high-performance building materials continues to grow, the use of nitrile rubber, neoprene, and SBR in rubber underlayment is expected to expand, driven by their ability to enhance the functionality and longevity of flooring and roofing systems. The versatility of these materials also supports innovation in product design, enabling the development of new solutions that address emerging challenges in the construction industry. With ongoing research and development efforts, the potential applications for nitrile rubber, neoprene, and SBR in rubber underlayment are likely to increase, further contributing to the growth of the global market.

Floor, Roofing in the Rubber Underlayment - Global Market:

Rubber underlayment is extensively used in flooring and roofing applications due to its beneficial properties, which enhance the performance and longevity of these structures. In flooring, rubber underlayment serves as a crucial component that provides sound insulation, cushioning, and moisture protection. It is particularly effective in reducing impact noise, such as footsteps, which is essential in multi-story buildings and apartments where noise transmission can be a significant concern. By absorbing sound, rubber underlayment helps create a quieter and more comfortable living environment. Additionally, its cushioning effect adds comfort underfoot, making it a popular choice for residential and commercial spaces. Rubber underlayment also acts as a moisture barrier, preventing water from seeping through to the subfloor and causing damage. This is especially important in areas prone to moisture, such as kitchens and bathrooms, where water resistance is a critical factor in maintaining the integrity of the flooring. In roofing applications, rubber underlayment provides an additional layer of protection against the elements. It is used as a waterproof barrier that prevents water infiltration, which can lead to leaks and structural damage. The flexibility and durability of rubber underlayment make it suitable for various roofing systems, including flat and sloped roofs. Its ability to withstand extreme temperatures and weather conditions ensures that the roofing system remains intact and functional over time. Moreover, rubber underlayment contributes to energy efficiency by providing thermal insulation, which helps regulate indoor temperatures and reduce energy consumption. This is particularly beneficial in regions with harsh climates, where maintaining a stable indoor environment is crucial for comfort and energy savings. The use of rubber underlayment in flooring and roofing applications is driven by its performance benefits, which enhance the overall quality and durability of these structures. As the construction industry continues to prioritize sustainability and efficiency, the demand for rubber underlayment is expected to grow, supported by its eco-friendly properties and ability to improve building performance.

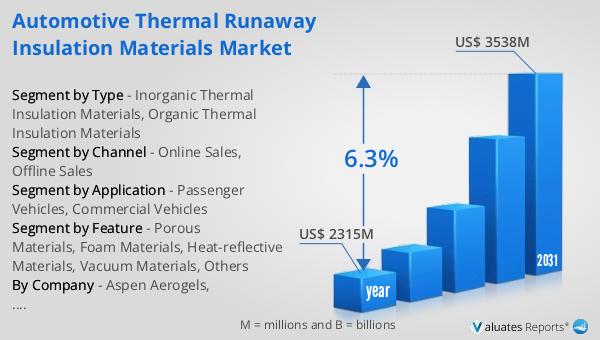

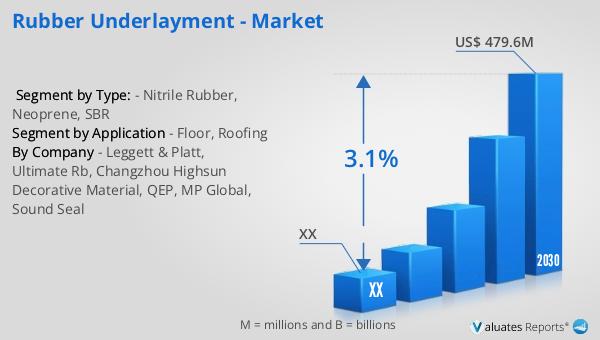

Rubber Underlayment - Global Market Outlook:

The global market for rubber underlayment was valued at approximately $382 million in 2023, with projections indicating a growth to around $479.6 million by 2030. This represents a compound annual growth rate (CAGR) of 3.1% over the forecast period from 2024 to 2030. This growth is driven by increasing demand for sustainable and high-performance building materials, as well as advancements in manufacturing technologies that enhance the quality and functionality of rubber underlayment products. In North America, the market for rubber underlayment was valued at a significant amount in 2023, with expectations of continued growth through 2030. The region's market dynamics are influenced by factors such as urbanization, construction activities, and consumer preference for eco-friendly materials. The steady growth rate reflects the ongoing adoption of rubber underlayment in various construction applications, including flooring and roofing, where its benefits in sound insulation, moisture protection, and durability are highly valued. As the market continues to evolve, manufacturers are likely to focus on innovation and product development to meet the changing needs of consumers and capitalize on emerging opportunities in the global market.

| Report Metric | Details |

| Report Name | Rubber Underlayment - Market |

| Forecasted market size in 2030 | US$ 479.6 million |

| CAGR | 3.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Leggett & Platt, Ultimate Rb, Changzhou Highsun Decorative Material, QEP, MP Global, Sound Seal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |