What is Global PVC Welding Cable Market?

The Global PVC Welding Cable Market refers to the worldwide industry focused on the production, distribution, and utilization of PVC (Polyvinyl Chloride) welding cables. These cables are essential components in various welding applications, providing the necessary electrical connection between welding machines and the materials being welded. PVC welding cables are known for their durability, flexibility, and resistance to heat, chemicals, and abrasion, making them suitable for both indoor and outdoor use. The market encompasses a wide range of products, including single-core and multi-core cables, each designed to meet specific requirements in different industries. The demand for PVC welding cables is driven by the growth in construction, automotive, and manufacturing sectors, where welding is a critical process. Additionally, advancements in welding technology and the increasing adoption of automated welding systems are further propelling the market. The global PVC welding cable market is characterized by a diverse range of manufacturers and suppliers, offering products that comply with international standards and regulations. As industries continue to expand and modernize, the need for reliable and efficient welding cables is expected to grow, making the global PVC welding cable market a vital component of the industrial landscape.

Single Core Cable, Multi-Core Cable in the Global PVC Welding Cable Market:

Single-core and multi-core cables are two primary types of PVC welding cables used in various applications. Single-core cables consist of a single conductor, typically made of copper or aluminum, surrounded by a layer of PVC insulation. These cables are known for their simplicity, ease of installation, and cost-effectiveness. They are commonly used in applications where flexibility and ease of handling are essential, such as in portable welding machines and temporary setups. Single-core cables are also favored for their ability to carry high currents, making them suitable for heavy-duty welding tasks. On the other hand, multi-core cables consist of multiple conductors, each individually insulated and bundled together within a single outer sheath. These cables offer greater versatility and are used in applications where multiple electrical connections are required. Multi-core cables are often employed in complex welding systems, where different components need to be connected simultaneously. They provide enhanced safety and reliability, as the individual conductors are insulated from each other, reducing the risk of short circuits. In the global PVC welding cable market, both single-core and multi-core cables are available in various sizes and specifications to meet the diverse needs of different industries. Manufacturers offer a wide range of products, from lightweight and flexible cables for portable welding machines to heavy-duty cables for industrial applications. The choice between single-core and multi-core cables depends on factors such as the specific requirements of the welding task, the environment in which the cables will be used, and the budget constraints of the project. As the demand for efficient and reliable welding solutions continues to grow, the market for both single-core and multi-core PVC welding cables is expected to expand, driven by advancements in technology and the increasing complexity of welding applications.

Household Appliances, Electrical Equipment, Welding Machine, Others in the Global PVC Welding Cable Market:

The usage of PVC welding cables extends across various sectors, including household appliances, electrical equipment, welding machines, and other applications. In household appliances, PVC welding cables are used in the manufacturing and repair of devices such as refrigerators, washing machines, and air conditioners. These cables provide the necessary electrical connections for welding components and ensuring the durability and safety of the appliances. In the electrical equipment sector, PVC welding cables are employed in the assembly and maintenance of electrical panels, transformers, and switchgear. They offer excellent insulation properties and resistance to heat and chemicals, making them ideal for use in harsh environments. Welding machines, both manual and automated, rely heavily on PVC welding cables for their operation. These cables connect the welding torch to the power source, ensuring a stable and efficient flow of electricity. The flexibility and durability of PVC welding cables make them suitable for use in various welding processes, including MIG, TIG, and arc welding. Additionally, PVC welding cables are used in other applications such as automotive manufacturing, construction, and shipbuilding. In the automotive industry, these cables are used in the welding of car bodies and components, ensuring strong and reliable joints. In construction, PVC welding cables are used in the fabrication of steel structures, pipelines, and other infrastructure projects. The shipbuilding industry also relies on PVC welding cables for the welding of hulls, decks, and other components. The versatility and reliability of PVC welding cables make them indispensable in these industries, contributing to the overall efficiency and safety of the welding processes. As industries continue to evolve and adopt new technologies, the demand for high-quality PVC welding cables is expected to increase, driving the growth of the global PVC welding cable market.

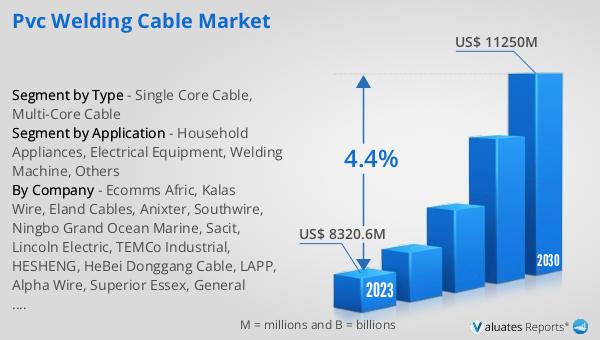

Global PVC Welding Cable Market Outlook:

The global PVC welding cable market was valued at approximately $8.32 billion in 2023 and is projected to reach around $11.25 billion by 2030, reflecting a compound annual growth rate (CAGR) of 4.4% during the forecast period from 2024 to 2030. This growth can be attributed to the increasing demand for efficient and reliable welding solutions across various industries, including construction, automotive, and manufacturing. The market is characterized by a diverse range of products, including single-core and multi-core cables, each designed to meet specific requirements in different applications. Manufacturers are focusing on developing advanced PVC welding cables that offer enhanced durability, flexibility, and resistance to heat and chemicals. Additionally, the adoption of automated welding systems and the growing emphasis on safety and efficiency in welding processes are driving the demand for high-quality PVC welding cables. As industries continue to expand and modernize, the need for reliable and efficient welding cables is expected to grow, making the global PVC welding cable market a vital component of the industrial landscape.

| Report Metric | Details |

| Report Name | PVC Welding Cable Market |

| Accounted market size in 2023 | US$ 8320.6 million |

| Forecasted market size in 2030 | US$ 11250 million |

| CAGR | 4.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ecomms Afric, Kalas Wire, Eland Cables, Anixter, Southwire, Ningbo Grand Ocean Marine, Sacit, Lincoln Electric, TEMCo Industrial, HESHENG, HeBei Donggang Cable, LAPP, Alpha Wire, Superior Essex, General Cable, Nexans |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |