What is Electrical Conductive Powder Coatings - Global Market?

Electrical conductive powder coatings are a specialized type of coating used to enhance the electrical conductivity of surfaces. These coatings are made from fine particles that, when applied to a surface, create a conductive layer. This is particularly useful in industries where static electricity can cause damage or where electrical conductivity is required for functionality. The global market for these coatings is growing due to increasing demand in various sectors such as electronics, automotive, and aerospace. These coatings offer several advantages, including improved durability, resistance to corrosion, and enhanced aesthetic appeal. They are also environmentally friendly, as they contain no volatile organic compounds (VOCs) and produce minimal waste during application. As industries continue to innovate and seek more efficient and sustainable solutions, the demand for electrical conductive powder coatings is expected to rise, driving growth in the global market. This growth is supported by advancements in technology and the development of new materials that enhance the performance of these coatings. Overall, electrical conductive powder coatings represent a significant opportunity for manufacturers and suppliers in the coatings industry.

Epoxy Coating, Epoxy-polyester (Hybrid) Coating, Polyester Resin Coating in the Electrical Conductive Powder Coatings - Global Market:

Epoxy coatings are a popular choice in the electrical conductive powder coatings market due to their excellent adhesion, chemical resistance, and durability. These coatings are made from epoxy resins, which are known for their strong bonding properties and ability to withstand harsh environmental conditions. Epoxy coatings are often used in applications where a tough, protective layer is needed, such as in industrial machinery and equipment. They provide a smooth, hard finish that is resistant to abrasion and impact, making them ideal for high-traffic areas. Additionally, epoxy coatings can be formulated to offer electrical conductivity, which is essential in applications where static electricity needs to be dissipated. Epoxy-polyester (hybrid) coatings combine the benefits of both epoxy and polyester resins, offering a balance of flexibility, durability, and chemical resistance. These coatings are often used in applications where a more flexible finish is required, such as in automotive parts and appliances. The hybrid nature of these coatings allows them to provide good adhesion and resistance to chipping and cracking, while also offering electrical conductivity. Polyester resin coatings are known for their excellent weatherability and UV resistance, making them suitable for outdoor applications. These coatings are often used in the construction and architectural industries, where they provide a durable, long-lasting finish that can withstand exposure to the elements. Polyester resin coatings can also be formulated to offer electrical conductivity, making them suitable for use in electronic enclosures and other applications where static electricity needs to be managed. Overall, the choice of coating depends on the specific requirements of the application, including the need for electrical conductivity, durability, and environmental resistance. Each type of coating offers unique benefits and can be tailored to meet the needs of different industries and applications. As the global market for electrical conductive powder coatings continues to grow, manufacturers are developing new formulations and technologies to enhance the performance and versatility of these coatings. This includes the development of coatings that offer improved conductivity, better adhesion, and enhanced resistance to environmental factors. By understanding the properties and benefits of different types of coatings, manufacturers and end-users can make informed decisions about the best solutions for their specific needs.

Electrical, Machine, Metal Surface Treatment, Medical Equipment, Other in the Electrical Conductive Powder Coatings - Global Market:

Electrical conductive powder coatings are used in a variety of applications across different industries, each with its own unique requirements and challenges. In the electrical industry, these coatings are used to enhance the conductivity of components and assemblies, ensuring efficient operation and reducing the risk of static discharge. This is particularly important in sensitive electronic devices, where even a small amount of static electricity can cause damage. By providing a conductive layer, these coatings help to protect components and improve their performance. In the machinery industry, electrical conductive powder coatings are used to protect equipment from wear and tear, while also providing a conductive surface that can help to dissipate static electricity. This is important in environments where machinery is exposed to dust, dirt, and other contaminants that can cause static buildup. By using conductive coatings, manufacturers can improve the reliability and longevity of their equipment. In the metal surface treatment industry, these coatings are used to provide a conductive layer on metal surfaces, improving their resistance to corrosion and wear. This is particularly important in applications where metal surfaces are exposed to harsh environmental conditions, such as in the automotive and aerospace industries. By providing a durable, conductive layer, these coatings help to extend the life of metal components and improve their performance. In the medical equipment industry, electrical conductive powder coatings are used to provide a conductive surface on medical devices and equipment, ensuring their safe and efficient operation. This is particularly important in applications where static electricity can interfere with the operation of sensitive medical equipment. By providing a conductive layer, these coatings help to protect equipment and improve its performance. In addition to these industries, electrical conductive powder coatings are also used in a variety of other applications, including in the construction and architectural industries, where they provide a durable, conductive finish that can withstand exposure to the elements. Overall, the use of electrical conductive powder coatings is growing across a wide range of industries, driven by the need for improved performance, durability, and environmental resistance. As the global market for these coatings continues to expand, manufacturers are developing new formulations and technologies to meet the evolving needs of different industries and applications.

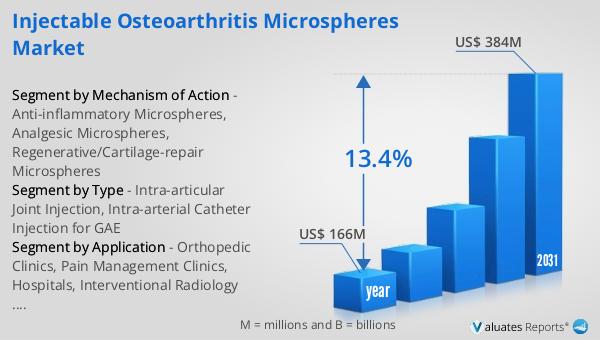

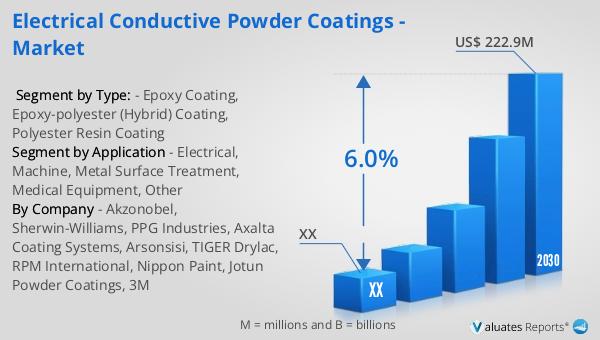

Electrical Conductive Powder Coatings - Global Market Outlook:

The global market for electrical conductive powder coatings was valued at approximately $147.7 million in 2023. This market is projected to grow significantly, reaching an estimated size of $222.9 million by 2030. This growth represents a compound annual growth rate (CAGR) of 6.0% during the forecast period from 2024 to 2030. The North American segment of this market also shows promising growth potential. Although specific figures for the North American market in 2023 and 2030 are not provided, it is expected to follow a similar upward trend as the global market. The increasing demand for electrical conductive powder coatings in various industries, such as electronics, automotive, and aerospace, is driving this growth. These coatings offer several advantages, including improved durability, resistance to corrosion, and enhanced aesthetic appeal, which are highly valued in these industries. Additionally, the environmental benefits of these coatings, such as the absence of volatile organic compounds (VOCs) and minimal waste production, further contribute to their growing popularity. As industries continue to innovate and seek more efficient and sustainable solutions, the demand for electrical conductive powder coatings is expected to rise, driving growth in both the global and North American markets.

| Report Metric | Details |

| Report Name | Electrical Conductive Powder Coatings - Market |

| Forecasted market size in 2030 | US$ 222.9 million |

| CAGR | 6.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Akzonobel, Sherwin-Williams, PPG Industries, Axalta Coating Systems, Arsonsisi, TIGER Drylac, RPM International, Nippon Paint, Jotun Powder Coatings, 3M |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |