What is Thermosetting Insulating Glass Sealants - Global Market?

Thermosetting insulating glass sealants are specialized materials used to bond and seal the edges of insulating glass units (IGUs), which are commonly found in windows and doors. These sealants are designed to provide a durable and long-lasting seal that can withstand various environmental conditions. Unlike thermoplastic sealants, thermosetting sealants undergo a chemical reaction during curing, resulting in a rigid and heat-resistant bond. This makes them particularly suitable for applications where high performance and durability are required. The global market for these sealants is driven by the increasing demand for energy-efficient buildings and the growing construction industry. As more countries adopt stringent energy regulations, the need for high-performance insulating glass units is expected to rise, further boosting the demand for thermosetting sealants. Additionally, advancements in sealant technology and the development of new formulations are likely to enhance the performance characteristics of these products, making them even more appealing to manufacturers and consumers alike. Overall, the thermosetting insulating glass sealants market is poised for steady growth as it continues to play a crucial role in the construction and energy sectors.

Polysulfide, Polyurethane, Silicone, Other in the Thermosetting Insulating Glass Sealants - Global Market:

Thermosetting insulating glass sealants are categorized into several types based on their chemical composition, including polysulfide, polyurethane, silicone, and other formulations. Each type offers distinct properties and advantages, making them suitable for various applications. Polysulfide sealants are known for their excellent chemical resistance and flexibility, making them ideal for use in environments where exposure to harsh chemicals or extreme temperatures is common. They provide a strong bond and are often used in the construction of insulating glass units for buildings and transportation vehicles. Polyurethane sealants, on the other hand, are valued for their superior adhesion and elasticity. They are commonly used in applications where movement and vibration are factors, such as in the automotive and aerospace industries. Polyurethane sealants also offer good resistance to weathering and UV radiation, making them suitable for outdoor applications. Silicone sealants are renowned for their exceptional temperature resistance and durability. They maintain their flexibility and adhesion properties over a wide temperature range, making them ideal for use in both hot and cold climates. Silicone sealants are often used in the construction of high-performance insulating glass units for buildings, as well as in the manufacturing of electronic devices and appliances. Other types of thermosetting sealants include epoxy and acrylic formulations, which offer unique properties such as high strength and fast curing times. These sealants are used in specialized applications where specific performance characteristics are required. Overall, the choice of sealant depends on the specific requirements of the application, including factors such as environmental conditions, mechanical stress, and chemical exposure. As the demand for energy-efficient and durable insulating glass units continues to grow, the market for thermosetting sealants is expected to expand, with manufacturers focusing on developing new formulations that offer enhanced performance and sustainability.

Building, Transportation, Refrigeration, Other in the Thermosetting Insulating Glass Sealants - Global Market:

Thermosetting insulating glass sealants are widely used in various industries, including building, transportation, refrigeration, and others, due to their superior performance characteristics. In the building industry, these sealants are essential for creating energy-efficient windows and doors. They provide a strong and durable seal that prevents air and moisture infiltration, helping to maintain indoor temperature and reduce energy consumption. This is particularly important in regions with extreme weather conditions, where maintaining a stable indoor environment is crucial for comfort and energy efficiency. In the transportation sector, thermosetting sealants are used in the manufacturing of vehicles, including cars, trucks, and airplanes. They provide a reliable seal that can withstand the vibrations and movements associated with transportation, ensuring the integrity of windows and other glass components. This is especially important for vehicles that operate in harsh environments, where exposure to extreme temperatures and chemicals is common. In the refrigeration industry, these sealants are used to create airtight seals in refrigeration units and appliances. This helps to maintain the efficiency of the cooling system and prevent the loss of cold air, which is essential for preserving food and other perishable items. Other applications of thermosetting insulating glass sealants include their use in the manufacturing of electronic devices, appliances, and industrial equipment. In these applications, the sealants provide a protective barrier against moisture, dust, and other contaminants, ensuring the longevity and reliability of the products. As industries continue to prioritize energy efficiency and sustainability, the demand for high-performance insulating glass sealants is expected to grow, driving innovation and development in the market.

Thermosetting Insulating Glass Sealants - Global Market Outlook:

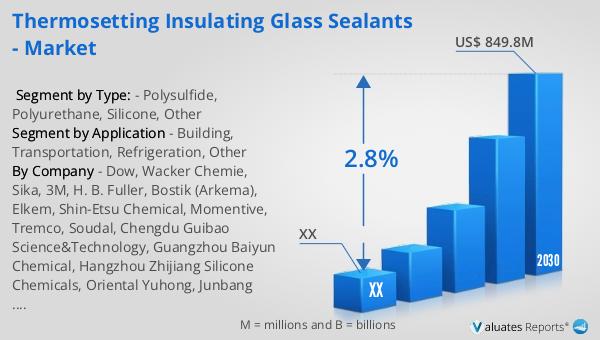

The global market for thermosetting insulating glass sealants was valued at approximately $700 million in 2023. It is projected to reach an adjusted size of $849.8 million by 2030, growing at a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030. This growth is attributed to the increasing preference for thermosetting sealants over thermoplastic alternatives in certain applications. Thermosetting sealants offer superior performance characteristics, such as enhanced durability, chemical resistance, and temperature stability, making them ideal for demanding environments. These properties are particularly important in industries such as construction, transportation, and refrigeration, where the integrity and longevity of insulating glass units are critical. As more countries implement stringent energy efficiency regulations, the demand for high-performance insulating glass units is expected to rise, further driving the growth of the thermosetting sealants market. Additionally, advancements in sealant technology and the development of new formulations are likely to enhance the performance and sustainability of these products, making them even more attractive to manufacturers and consumers. Overall, the thermosetting insulating glass sealants market is poised for steady growth as it continues to play a vital role in various industries.

| Report Metric | Details |

| Report Name | Thermosetting Insulating Glass Sealants - Market |

| Forecasted market size in 2030 | US$ 849.8 million |

| CAGR | 2.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dow, Wacker Chemie, Sika, 3M, H. B. Fuller, Bostik (Arkema), Elkem, Shin-Etsu Chemical, Momentive, Tremco, Soudal, Chengdu Guibao Science&Technology, Guangzhou Baiyun Chemical, Hangzhou Zhijiang Silicone Chemicals, Oriental Yuhong, Junbang Group, Guangzhou Jointas Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |