What is Anti-static Powder Coating - Global Market?

Anti-static powder coating is a specialized type of coating used globally to prevent static electricity buildup on surfaces. This coating is particularly important in industries where static electricity can cause significant problems, such as in electronics manufacturing, where static discharge can damage sensitive components. The global market for anti-static powder coating is growing as industries increasingly recognize the importance of protecting their products and processes from static-related issues. These coatings are made from a combination of conductive and non-conductive materials, which together provide a balance of electrical conductivity and durability. This dual functionality makes them ideal for a wide range of applications, from protecting electronic devices to enhancing the safety and longevity of industrial machinery. As industries continue to innovate and expand, the demand for reliable anti-static solutions is expected to rise, driving further growth in the market. The coatings are also environmentally friendly, as they do not contain volatile organic compounds (VOCs), making them a preferred choice for companies looking to reduce their environmental impact. Overall, the anti-static powder coating market is poised for significant growth as more industries adopt these solutions to enhance safety and performance.

Thermoplastic, Thermoset in the Anti-static Powder Coating - Global Market:

Thermoplastic and thermoset are two primary types of materials used in anti-static powder coatings, each offering distinct properties and benefits. Thermoplastic coatings are known for their ability to be melted and reformed multiple times without undergoing any significant chemical change. This characteristic makes them highly versatile and easy to apply, as they can be reheated and adjusted as needed. Thermoplastic coatings are typically used in applications where flexibility and impact resistance are crucial, such as in automotive parts and consumer electronics. They provide a durable, protective layer that can withstand physical stress and environmental factors, making them ideal for outdoor and high-traffic areas. On the other hand, thermoset coatings undergo a chemical change when cured, creating a rigid, cross-linked structure that cannot be remelted. This makes them exceptionally hard and resistant to heat, chemicals, and abrasion. Thermoset coatings are often used in industrial applications where long-term durability and resistance to harsh conditions are required, such as in machinery and equipment used in manufacturing and construction. Both thermoplastic and thermoset coatings can be formulated to include anti-static properties, providing the necessary protection against static electricity while maintaining their inherent benefits. The choice between thermoplastic and thermoset coatings depends largely on the specific requirements of the application, including factors such as environmental conditions, mechanical stress, and desired lifespan. In the global market, both types of coatings are in demand, with industries selecting the appropriate material based on their unique needs and challenges. As technology advances and new materials are developed, the capabilities and applications of anti-static powder coatings continue to expand, offering even greater protection and performance across a wide range of industries. The versatility and effectiveness of these coatings make them an essential component in modern manufacturing and production processes, helping to ensure the safety and reliability of products and systems worldwide.

Electrical, Machine, Metal Surface Treatment, Medical Equipment, Other in the Anti-static Powder Coating - Global Market:

Anti-static powder coatings are used in various sectors, each with specific requirements and benefits. In the electrical industry, these coatings are crucial for preventing static discharge, which can damage sensitive electronic components and lead to costly failures. By applying anti-static coatings, manufacturers can protect their products and ensure their longevity and reliability. In the machinery sector, anti-static coatings help reduce the risk of static buildup, which can cause sparks and potentially ignite flammable materials. This is particularly important in industries such as oil and gas, where safety is paramount. The coatings also provide a protective layer that enhances the durability and lifespan of machinery, reducing maintenance costs and downtime. For metal surface treatment, anti-static powder coatings offer a dual benefit of preventing static electricity and providing a robust, corrosion-resistant finish. This makes them ideal for use in harsh environments where metal surfaces are exposed to moisture, chemicals, and other corrosive elements. In the medical equipment industry, anti-static coatings are used to protect sensitive devices from static discharge, which can interfere with their operation and accuracy. These coatings also help maintain a sterile environment by providing a smooth, easy-to-clean surface that resists the buildup of dust and contaminants. Other industries, such as automotive and aerospace, also benefit from anti-static powder coatings, using them to enhance the safety and performance of their products. The versatility and effectiveness of these coatings make them a valuable tool for manufacturers looking to improve the safety, reliability, and longevity of their products. As industries continue to evolve and face new challenges, the demand for anti-static solutions is expected to grow, driving further innovation and development in the market.

Anti-static Powder Coating - Global Market Outlook:

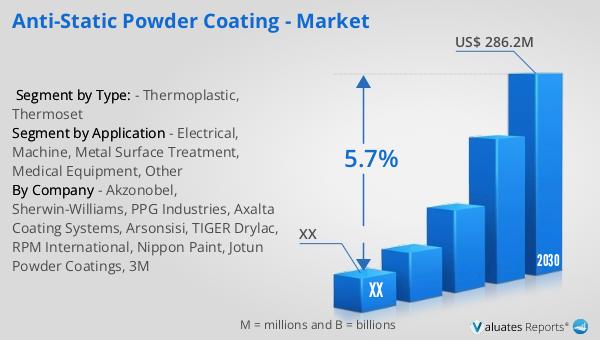

The global market for anti-static powder coating was valued at approximately $192.9 million in 2023, with projections indicating a growth to around $286.2 million by 2030. This represents a compound annual growth rate (CAGR) of 5.7% during the forecast period from 2024 to 2030. Anti-static powder coatings are crafted from a blend of conductive and non-conductive materials, offering a unique combination of electrical conductivity and durability. This makes them particularly valuable in industries where static electricity can pose significant risks, such as electronics, automotive, and industrial manufacturing. The coatings not only protect sensitive components from static discharge but also enhance the overall durability and lifespan of the products. As industries continue to prioritize safety and efficiency, the demand for reliable anti-static solutions is expected to increase, driving further growth in the market. The coatings are also environmentally friendly, as they do not contain volatile organic compounds (VOCs), making them a preferred choice for companies looking to reduce their environmental impact. Overall, the anti-static powder coating market is poised for significant growth as more industries adopt these solutions to enhance safety and performance.

| Report Metric | Details |

| Report Name | Anti-static Powder Coating - Market |

| Forecasted market size in 2030 | US$ 286.2 million |

| CAGR | 5.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Akzonobel, Sherwin-Williams, PPG Industries, Axalta Coating Systems, Arsonsisi, TIGER Drylac, RPM International, Nippon Paint, Jotun Powder Coatings, 3M |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |