What is Air Springs for Vehicle Suspension - Global Market?

Air springs for vehicle suspension are a crucial component in modern automotive systems, designed to enhance ride quality and vehicle handling. These components replace traditional steel springs with air-filled bags, offering a smoother and more adaptable suspension system. The global market for air springs is driven by the increasing demand for improved vehicle comfort and performance. As vehicles become more advanced, the need for sophisticated suspension systems that can adapt to various road conditions and loads has grown. Air springs provide this adaptability, allowing for better control over vehicle dynamics. They are particularly beneficial in heavy-duty vehicles, where load variations are significant. The market is also influenced by the growing trend towards electric and hybrid vehicles, which often require advanced suspension systems to manage battery weight and distribution. Additionally, the rise in commercial transportation and logistics has spurred demand for air springs, as they help maintain vehicle stability and cargo safety. With advancements in materials and technology, air springs are becoming more durable and efficient, further driving their adoption across different vehicle segments. As a result, the global market for air springs is poised for significant growth, reflecting the broader trends in the automotive industry towards enhanced performance and sustainability.

Single Convolute, Multi Convolute in the Air Springs for Vehicle Suspension - Global Market:

Air springs for vehicle suspension come in various designs, with single convolute and multi convolute being two primary types. Single convolute air springs are characterized by their single-layered, bellows-like structure. This design is typically used in applications where space is limited, and a compact suspension solution is required. Single convolute air springs offer a straightforward design that provides a moderate level of ride comfort and load-carrying capacity. They are often used in lighter vehicles or in applications where the suspension system does not need to accommodate significant load variations. On the other hand, multi convolute air springs feature multiple layers or convolutions, which allow for greater flexibility and load-bearing capacity. This design is ideal for heavy-duty applications, such as trucks and buses, where the suspension system must handle substantial weight and provide a high level of ride comfort. Multi convolute air springs can adjust to varying loads and road conditions, offering superior performance compared to single convolute designs. The choice between single and multi convolute air springs depends on several factors, including the vehicle type, load requirements, and desired ride quality. In the global market, the demand for multi convolute air springs is generally higher due to their versatility and ability to provide enhanced performance in demanding applications. However, single convolute air springs remain popular in specific niches where their compact design and cost-effectiveness are advantageous. As the automotive industry continues to evolve, manufacturers are investing in research and development to improve the performance and durability of both single and multi convolute air springs. Innovations in materials, such as reinforced rubber and advanced composites, are helping to extend the lifespan of these components and improve their resistance to wear and environmental factors. Additionally, advancements in manufacturing processes are enabling more precise control over the production of air springs, resulting in products that offer consistent performance and reliability. The global market for air springs is also being shaped by regulatory trends, as governments worldwide implement stricter emissions and safety standards. These regulations are driving the adoption of advanced suspension systems, including air springs, as manufacturers seek to meet these requirements while maintaining vehicle performance and comfort. In summary, single convolute and multi convolute air springs each offer unique benefits and are suited to different applications within the vehicle suspension market. As technology advances and market demands evolve, both types of air springs are expected to play a critical role in the future of automotive suspension systems.

Passenger Car, Commercial Vehicle in the Air Springs for Vehicle Suspension - Global Market:

Air springs for vehicle suspension are widely used in both passenger cars and commercial vehicles, each with distinct applications and benefits. In passenger cars, air springs are primarily used to enhance ride comfort and handling. They allow for a smoother ride by absorbing road imperfections and reducing vibrations transmitted to the cabin. This is particularly important in luxury vehicles, where passenger comfort is a top priority. Air springs also enable adjustable ride height, which can improve aerodynamics and fuel efficiency at higher speeds. In addition, they provide better handling by maintaining optimal tire contact with the road, which is crucial for safety and performance. In commercial vehicles, such as trucks and buses, air springs play a vital role in load management and vehicle stability. These vehicles often carry heavy and variable loads, which can affect handling and safety. Air springs help maintain a consistent ride height regardless of the load, ensuring that the vehicle remains stable and controllable. This is especially important for long-haul trucks and buses, where driver fatigue and cargo safety are significant concerns. Air springs also contribute to reduced wear and tear on the vehicle's suspension components, leading to lower maintenance costs and longer vehicle lifespan. Furthermore, air springs can improve fuel efficiency in commercial vehicles by optimizing the vehicle's aerodynamics and reducing rolling resistance. As the global market for air springs continues to grow, manufacturers are focusing on developing advanced systems that offer improved performance and durability for both passenger cars and commercial vehicles. This includes the integration of electronic controls that allow for real-time adjustments to the suspension system based on driving conditions and load. Such innovations are expected to further enhance the benefits of air springs, making them an increasingly popular choice in the automotive industry. Overall, the use of air springs in passenger cars and commercial vehicles highlights their versatility and effectiveness in improving ride quality, handling, and safety across a wide range of applications.

Air Springs for Vehicle Suspension - Global Market Outlook:

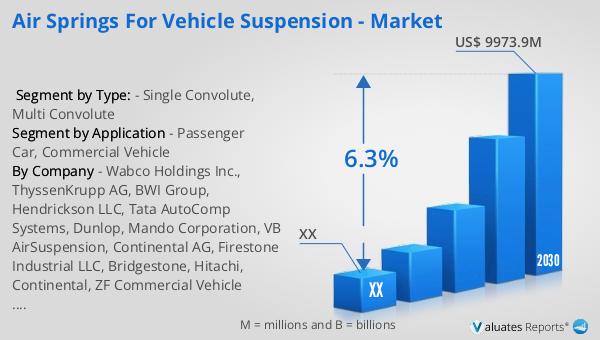

The global market for air springs for vehicle suspension was valued at approximately $6.8 billion in 2023. This market is projected to grow significantly, reaching an estimated size of $9.97 billion by 2030. This growth represents a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. The increasing demand for air springs is driven by several factors, including the need for improved vehicle comfort and performance, as well as the growing trend towards electric and hybrid vehicles. As these vehicles become more prevalent, the demand for advanced suspension systems that can accommodate their unique weight distribution and performance requirements is expected to rise. Additionally, the expansion of the commercial transportation and logistics sectors is contributing to the growth of the air springs market, as these industries require reliable and efficient suspension systems to ensure vehicle stability and cargo safety. The market is also being influenced by advancements in materials and technology, which are leading to the development of more durable and efficient air springs. As a result, the global market for air springs is poised for significant growth, reflecting the broader trends in the automotive industry towards enhanced performance and sustainability.

| Report Metric | Details |

| Report Name | Air Springs for Vehicle Suspension - Market |

| Forecasted market size in 2030 | US$ 9973.9 million |

| CAGR | 6.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Wabco Holdings Inc., ThyssenKrupp AG, BWI Group, Hendrickson LLC, Tata AutoComp Systems, Dunlop, Mando Corporation, VB AirSuspension, Continental AG, Firestone Industrial LLC, Bridgestone, Hitachi, Continental, ZF Commercial Vehicle Control Systems, Trelleborg Vibracoustic, Thyssenkrupp, Hendrickson International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |