What is PVC Thermoplastic Powder Coatings - Global Market?

PVC Thermoplastic Powder Coatings are a type of coating material used in various industries for their durability and versatility. These coatings are made from polyvinyl chloride (PVC), a type of plastic that becomes pliable when heated and hardens upon cooling. This thermoplastic nature allows the coatings to be applied in a powder form, which is then melted and fused onto surfaces to create a smooth, protective layer. The global market for PVC Thermoplastic Powder Coatings is driven by their application in industries such as construction, automotive, and electronics, where they are valued for their resistance to corrosion, chemicals, and weathering. These coatings are also environmentally friendly, as they contain no volatile organic compounds (VOCs) and produce minimal waste during application. As industries continue to seek sustainable and efficient coating solutions, the demand for PVC Thermoplastic Powder Coatings is expected to grow, offering a promising outlook for the market.

PVC Homopolymer, PVC Copolymer in the PVC Thermoplastic Powder Coatings - Global Market:

PVC Homopolymer and PVC Copolymer are two types of PVC used in thermoplastic powder coatings, each with distinct properties and applications. PVC Homopolymer is the most common form of PVC, consisting of polymerized vinyl chloride monomers. It is known for its excellent mechanical properties, chemical resistance, and cost-effectiveness. These characteristics make PVC Homopolymer an ideal choice for applications requiring durability and resistance to harsh environments, such as in construction and industrial settings. On the other hand, PVC Copolymer is created by polymerizing vinyl chloride with other monomers, such as vinyl acetate or vinylidene chloride. This modification enhances certain properties of the PVC, such as flexibility, impact resistance, and clarity. PVC Copolymer is often used in applications where these enhanced properties are desirable, such as in consumer goods and packaging. In the context of PVC Thermoplastic Powder Coatings, both PVC Homopolymer and PVC Copolymer offer unique advantages. PVC Homopolymer-based coatings are typically used in applications where high strength and chemical resistance are paramount, such as in protective coatings for metal surfaces exposed to corrosive environments. These coatings provide a robust barrier against moisture, chemicals, and physical wear, extending the lifespan of the coated materials. PVC Copolymer-based coatings, with their improved flexibility and impact resistance, are often chosen for applications where the coated surfaces may experience mechanical stress or require a more pliable finish. This makes them suitable for use in automotive parts, flexible packaging, and certain types of construction materials. The choice between PVC Homopolymer and PVC Copolymer in thermoplastic powder coatings depends on the specific requirements of the application, including the desired balance of strength, flexibility, and resistance properties. Both types of PVC offer valuable solutions for different industrial needs, contributing to the versatility and adaptability of PVC Thermoplastic Powder Coatings in the global market. As industries continue to innovate and seek materials that meet stringent performance and environmental standards, the demand for both PVC Homopolymer and PVC Copolymer in thermoplastic powder coatings is likely to remain strong.

Interior Construction Material, Exterior Construction Materials, Electric Appliances, Transportation, Other in the PVC Thermoplastic Powder Coatings - Global Market:

PVC Thermoplastic Powder Coatings find extensive usage across various sectors due to their robust properties and adaptability. In the realm of interior construction materials, these coatings are prized for their ability to provide a durable and aesthetically pleasing finish. They are commonly applied to surfaces such as walls, ceilings, and furniture, where they offer protection against scratches, stains, and moisture. The smooth, uniform finish achieved with PVC coatings enhances the visual appeal of interior spaces while ensuring long-lasting performance. For exterior construction materials, PVC Thermoplastic Powder Coatings offer excellent resistance to weathering, UV radiation, and corrosion. These properties make them ideal for use on building facades, roofing materials, and outdoor fixtures, where they help maintain structural integrity and appearance over time. The coatings' ability to withstand harsh environmental conditions ensures that exterior surfaces remain protected and visually appealing, even in challenging climates. In the electric appliances sector, PVC Thermoplastic Powder Coatings are used to coat components such as housings, panels, and connectors. The coatings provide electrical insulation, chemical resistance, and a smooth finish, enhancing the safety and longevity of the appliances. Additionally, the coatings' non-toxic nature and absence of VOCs make them a preferred choice for manufacturers seeking environmentally friendly solutions. The transportation industry also benefits from the application of PVC Thermoplastic Powder Coatings. These coatings are used on automotive parts, railings, and other transportation-related components to provide protection against corrosion, abrasion, and impact. The coatings' ability to withstand mechanical stress and harsh environmental conditions ensures that vehicles and transportation infrastructure remain reliable and durable. Beyond these specific sectors, PVC Thermoplastic Powder Coatings are used in various other applications, including consumer goods, industrial equipment, and packaging. Their versatility, combined with their protective and aesthetic properties, makes them a valuable solution for a wide range of industries seeking high-performance coatings. As the demand for sustainable and efficient coating solutions continues to grow, the usage of PVC Thermoplastic Powder Coatings in these areas is expected to expand, driving further innovation and development in the market.

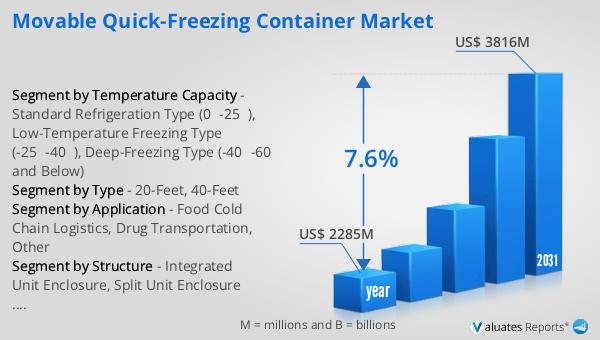

PVC Thermoplastic Powder Coatings - Global Market Outlook:

In 2023, the global market for PVC Thermoplastic Powder Coatings was valued at approximately US$ 219.8 million. Looking ahead, this market is projected to reach an adjusted size of US$ 313.3 million by the year 2030. This growth represents a compound annual growth rate (CAGR) of 5.0% over the forecast period from 2024 to 2030. This upward trend indicates a steady increase in demand for PVC Thermoplastic Powder Coatings across various industries. The anticipated growth can be attributed to several factors, including the rising need for durable and environmentally friendly coating solutions, advancements in coating technologies, and the expanding applications of these coatings in sectors such as construction, automotive, and electronics. As industries continue to prioritize sustainability and efficiency, the market for PVC Thermoplastic Powder Coatings is expected to experience significant growth, offering opportunities for manufacturers and suppliers to innovate and meet the evolving needs of their customers. The projected market expansion underscores the importance of PVC Thermoplastic Powder Coatings as a key player in the global coatings industry, with a promising outlook for the future.

| Report Metric | Details |

| Report Name | PVC Thermoplastic Powder Coatings - Market |

| Forecasted market size in 2030 | US$ 313.3 million |

| CAGR | 5.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Akzonobel, Sherwin-Williams, PPG Industries, Axalta Coating Systems, Arsonsisi, TIGER Drylac, RPM International, Nippon Paint, Jotun Powder Coatings, 3M, TITAN Powder Coatings, Teknos, Masco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |