What is Powder Coatings for Home Appliances - Global Market?

Powder coatings for home appliances represent a significant segment in the global market, offering a durable and aesthetically pleasing finish to various household items. These coatings are applied as a free-flowing, dry powder and are typically used to create a hard finish that is tougher than conventional paint. The process involves applying the powder electrostatically and then curing it under heat, which allows it to form a skin. This method is not only environmentally friendly, as it emits fewer volatile organic compounds (VOCs) compared to liquid coatings, but also cost-effective due to its high efficiency and minimal waste. The global market for powder coatings in home appliances is driven by the increasing demand for durable and high-quality finishes that can withstand the rigors of daily use. As consumers continue to seek appliances that are not only functional but also visually appealing, the demand for powder coatings is expected to grow. This market is characterized by continuous innovation, with manufacturers constantly developing new formulations to meet the evolving needs of consumers and regulatory standards. The versatility of powder coatings, combined with their environmental benefits, makes them an attractive choice for appliance manufacturers worldwide.

Thermoplastic Powder Coating, Thermosetting Powder Coatings in the Powder Coatings for Home Appliances - Global Market:

Thermoplastic and thermosetting powder coatings are two primary types of powder coatings used in the home appliances market, each offering distinct properties and benefits. Thermoplastic powder coatings are known for their ability to melt and flow when heated, and they solidify upon cooling. This characteristic allows them to be remelted and reshaped, making them ideal for applications where flexibility and impact resistance are crucial. Common thermoplastic powders include polyethylene, polyvinyl chloride (PVC), and nylon. These coatings are often used in applications requiring a thick, protective layer, such as on refrigerator shelves or washing machine drums. Their excellent chemical resistance and ability to withstand physical stress make them a popular choice for appliances that are frequently exposed to harsh conditions. On the other hand, thermosetting powder coatings undergo a chemical reaction during the curing process, forming a rigid, cross-linked structure that cannot be remelted. This makes them highly durable and resistant to heat, chemicals, and UV light. Epoxy, polyester, and acrylic are common types of thermosetting powders used in the appliance industry. These coatings are particularly valued for their superior adhesion and corrosion resistance, making them suitable for exterior parts of appliances like washing machine panels and refrigerator doors. The choice between thermoplastic and thermosetting powder coatings often depends on the specific requirements of the appliance and the desired properties of the finish. For instance, thermosetting coatings are preferred for applications where a hard, scratch-resistant surface is needed, while thermoplastic coatings are chosen for their flexibility and impact resistance. Both types of coatings contribute to the overall durability and longevity of home appliances, ensuring they maintain their appearance and functionality over time. As the demand for high-performance, environmentally friendly coatings continues to rise, manufacturers are investing in research and development to enhance the properties of both thermoplastic and thermosetting powders. This includes improving their application processes, expanding their color ranges, and increasing their resistance to environmental factors. The global market for powder coatings in home appliances is poised for growth as manufacturers seek to meet consumer demands for durable, aesthetically pleasing, and sustainable products. By understanding the unique properties and applications of thermoplastic and thermosetting powder coatings, manufacturers can make informed decisions that enhance the quality and performance of their appliances.

Refrigerator, Washing Machine, Air Conditioner, TV, Micro-wave Oven, Water Heater, Lighting, Other in the Powder Coatings for Home Appliances - Global Market:

The use of powder coatings in home appliances spans a wide range of products, each benefiting from the unique properties of these coatings. Refrigerators, for instance, often utilize powder coatings on their exterior surfaces to provide a durable, scratch-resistant finish that can withstand daily wear and tear. The coatings also offer excellent corrosion resistance, which is crucial for maintaining the appliance's appearance and functionality over time. In washing machines, powder coatings are applied to both the exterior and interior components, such as the drum and panels. These coatings protect against moisture and chemical exposure, ensuring the machine's longevity and performance. Air conditioners also benefit from powder coatings, particularly on their outdoor units, where resistance to UV light and harsh weather conditions is essential. The coatings help prevent rust and degradation, extending the life of the unit. Televisions, while not exposed to the same environmental factors as other appliances, use powder coatings to achieve a sleek, modern finish that enhances their aesthetic appeal. Microwave ovens, on the other hand, require coatings that can withstand high temperatures and frequent use. Powder coatings provide a robust, heat-resistant finish that maintains its integrity over time. Water heaters, which are often exposed to moisture and varying temperatures, benefit from the corrosion resistance and durability of powder coatings. These coatings help prevent rust and leaks, ensuring the appliance's efficiency and safety. Lighting fixtures, particularly those used outdoors, also utilize powder coatings for their weather-resistant properties. The coatings protect against UV light, moisture, and temperature fluctuations, ensuring the fixtures remain functional and visually appealing. Other appliances, such as dishwashers and ovens, also benefit from the protective and aesthetic qualities of powder coatings. The versatility of these coatings allows manufacturers to tailor them to the specific needs of each appliance, ensuring optimal performance and longevity. As the demand for high-quality, durable home appliances continues to grow, the use of powder coatings is expected to increase, driven by their ability to enhance both the functionality and appearance of these products.

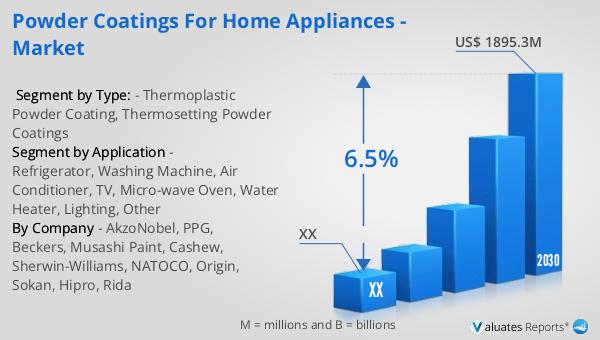

Powder Coatings for Home Appliances - Global Market Outlook:

In 2023, the global market for powder coatings used in home appliances was valued at approximately US$ 1220.9 million. This market is projected to grow significantly, reaching an estimated size of US$ 1895.3 million by 2030, with a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2024 to 2030. This growth is largely attributed to the numerous advantages that powder coatings offer, such as their exceptional durability, corrosion resistance, wear resistance, and color stability. These properties make powder coatings an attractive option for manufacturers looking to enhance the quality and longevity of their products. The increasing consumer demand for appliances that are not only functional but also aesthetically pleasing is driving the adoption of powder coatings in the industry. As manufacturers continue to innovate and develop new formulations, the market for powder coatings in home appliances is expected to expand further. The environmental benefits of powder coatings, including their low VOC emissions and high efficiency, also contribute to their growing popularity. As the market evolves, manufacturers are likely to focus on improving the performance and sustainability of their coatings to meet the changing needs of consumers and regulatory standards.

| Report Metric | Details |

| Report Name | Powder Coatings for Home Appliances - Market |

| Forecasted market size in 2030 | US$ 1895.3 million |

| CAGR | 6.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | AkzoNobel, PPG, Beckers, Musashi Paint, Cashew, Sherwin-Williams, NATOCO, Origin, Sokan, Hipro, Rida |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |