What is Heat Resistant Powder Coatings - Global Market?

Heat resistant powder coatings are specialized coatings designed to withstand high temperatures without degrading or losing their protective properties. These coatings are used in various industries where components are exposed to extreme heat, such as automotive, aerospace, and industrial manufacturing. The global market for heat resistant powder coatings is driven by the increasing demand for durable and efficient coatings that can protect equipment and structures from heat-induced damage. These coatings are typically made from resins like silicone, epoxy, or polyester, which are formulated to resist thermal degradation. They provide excellent adhesion, corrosion resistance, and color retention, even at elevated temperatures. The market is expanding due to the growing need for energy-efficient and environmentally friendly coatings that reduce maintenance costs and extend the lifespan of equipment. As industries continue to seek solutions that enhance performance and sustainability, the demand for heat resistant powder coatings is expected to rise. These coatings not only offer protection but also contribute to improved safety and efficiency in high-temperature environments. The global market is characterized by innovation and technological advancements, with manufacturers focusing on developing coatings that meet specific industry requirements and regulatory standards.

200°C, 300°C, 350°C, 400°C, Above 500°C in the Heat Resistant Powder Coatings - Global Market:

Heat resistant powder coatings are categorized based on their ability to withstand different temperature ranges, such as 200°C, 300°C, 350°C, 400°C, and above 500°C. Each category serves specific applications and industries, depending on the thermal demands of the environment. Coatings that can withstand up to 200°C are typically used in applications where moderate heat resistance is required, such as household appliances and automotive components. These coatings provide a balance between cost-effectiveness and performance, making them suitable for products that experience occasional heat exposure. Moving up the temperature scale, coatings that can endure up to 300°C are often employed in industrial machinery and equipment that operate under higher thermal stress. These coatings offer enhanced durability and protection against heat-induced wear and tear, ensuring the longevity of the equipment. At 350°C, the coatings are designed for more demanding applications, such as exhaust systems and heat exchangers, where consistent exposure to high temperatures is common. These coatings must maintain their integrity and protective properties to prevent corrosion and degradation. For environments that reach 400°C, the coatings are formulated to provide superior thermal stability and resistance to oxidation. These are crucial in industries like metallurgy and chemical processing, where equipment is subjected to extreme heat and corrosive substances. Finally, coatings that can withstand temperatures above 500°C are used in the most challenging conditions, such as in aerospace and power generation. These coatings are engineered to offer exceptional heat resistance, ensuring the safety and efficiency of critical components. The development of these high-performance coatings involves advanced materials and technologies, reflecting the industry's commitment to innovation and quality. As the demand for heat resistant powder coatings continues to grow, manufacturers are investing in research and development to create coatings that meet the evolving needs of various sectors. This includes improving the environmental profile of these coatings by reducing volatile organic compounds (VOCs) and enhancing their recyclability. The global market for heat resistant powder coatings is poised for growth as industries seek solutions that offer both performance and sustainability.

Electrical, Metallurgy, Oil & Gas, Aviation, Chemical, Pharmaceutical, Food Processing, Other in the Heat Resistant Powder Coatings - Global Market:

Heat resistant powder coatings find extensive usage across various industries due to their ability to protect equipment and structures from high temperatures and harsh conditions. In the electrical industry, these coatings are used to insulate and protect components such as transformers, motors, and switchgear from heat and electrical stress. They ensure the reliability and efficiency of electrical systems by preventing overheating and electrical failures. In metallurgy, heat resistant powder coatings are applied to furnaces, kilns, and other high-temperature equipment to prevent oxidation and corrosion. These coatings extend the lifespan of the equipment and reduce maintenance costs, contributing to improved operational efficiency. The oil and gas industry relies on these coatings to protect pipelines, valves, and other infrastructure from the extreme temperatures and corrosive environments encountered during extraction and processing. In aviation, heat resistant powder coatings are used on engine components, exhaust systems, and other parts exposed to high temperatures. They enhance the performance and safety of aircraft by providing thermal protection and reducing the risk of component failure. The chemical industry utilizes these coatings to protect reactors, storage tanks, and piping systems from heat and chemical exposure. This ensures the safe and efficient operation of chemical processes. In the pharmaceutical industry, heat resistant powder coatings are used to coat equipment and machinery that are subjected to sterilization processes involving high temperatures. These coatings help maintain the integrity and cleanliness of the equipment, ensuring compliance with stringent regulatory standards. The food processing industry also benefits from these coatings, as they are used to protect ovens, grills, and other cooking equipment from heat and corrosion. This enhances food safety and quality by preventing contamination and ensuring consistent cooking performance. Other industries, such as automotive and construction, also utilize heat resistant powder coatings to protect components and structures from heat-related damage. The versatility and effectiveness of these coatings make them an essential solution for industries seeking to enhance the durability and performance of their products and infrastructure. As the demand for heat resistant powder coatings continues to grow, manufacturers are focusing on developing coatings that meet the specific needs of each industry, ensuring optimal performance and protection.

Heat Resistant Powder Coatings - Global Market Outlook:

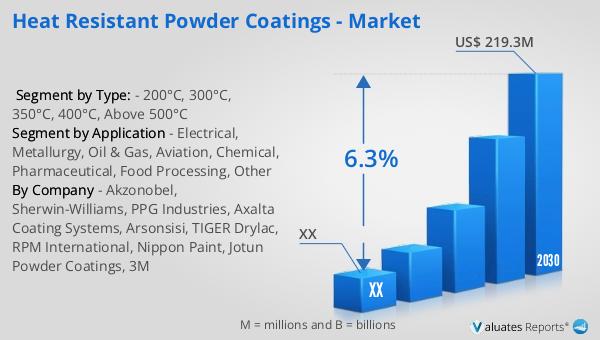

The global market for heat resistant powder coatings was valued at approximately $142.8 million in 2023. It is projected to grow to a revised size of $219.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for durable and efficient coatings that can withstand high temperatures across various industries. In North America, the market for heat resistant powder coatings was valued at a significant amount in 2023 and is expected to reach a higher value by 2030, with a steady CAGR during the forecast period. The growth in this region is attributed to the expanding industrial sector and the rising need for advanced coatings that offer superior thermal protection. As industries continue to prioritize safety, efficiency, and sustainability, the demand for heat resistant powder coatings is expected to rise, driving market growth globally. Manufacturers are focusing on innovation and technological advancements to develop coatings that meet the evolving needs of different sectors, ensuring optimal performance and protection in high-temperature environments. The market outlook remains positive, with opportunities for growth and development in various regions worldwide.

| Report Metric | Details |

| Report Name | Heat Resistant Powder Coatings - Market |

| Forecasted market size in 2030 | US$ 219.3 million |

| CAGR | 6.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Akzonobel, Sherwin-Williams, PPG Industries, Axalta Coating Systems, Arsonsisi, TIGER Drylac, RPM International, Nippon Paint, Jotun Powder Coatings, 3M |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |