What is Plastic Diaphragm Pumps - Global Market?

Plastic diaphragm pumps are a crucial component in various industries due to their versatility and efficiency. These pumps use a flexible diaphragm to move fluids, making them ideal for handling a wide range of liquids, including those with high viscosity or containing solids. The global market for plastic diaphragm pumps is expanding as industries seek reliable and cost-effective solutions for fluid transfer. These pumps are particularly valued for their ability to handle corrosive and abrasive fluids without damage, thanks to the durable plastic materials used in their construction. The market is driven by increasing demand in sectors such as water and wastewater treatment, oil and gas, chemicals, and food and beverages. As industries continue to prioritize sustainability and efficiency, the adoption of plastic diaphragm pumps is expected to grow, offering a promising outlook for manufacturers and suppliers in this field. The adaptability of these pumps to various operational conditions and their low maintenance requirements further enhance their appeal across different applications.

Air Operated Diaphragm Pump, Electrically Operated Diaphragm Pump, Others in the Plastic Diaphragm Pumps - Global Market:

Air operated diaphragm pumps, electrically operated diaphragm pumps, and other types of diaphragm pumps each play a significant role in the global market for plastic diaphragm pumps. Air operated diaphragm pumps are powered by compressed air, making them suitable for environments where electricity is not available or where explosive atmospheres are a concern. These pumps are known for their ability to handle a wide range of fluids, including those with high viscosity or containing solids. They are often used in industries such as chemicals, mining, and wastewater treatment due to their robust design and ability to operate in harsh conditions. Electrically operated diaphragm pumps, on the other hand, are powered by an electric motor, offering precise control over flow rates and pressure. These pumps are ideal for applications requiring consistent and reliable performance, such as in the food and beverage industry, where hygiene and precision are paramount. The electric operation allows for easy integration into automated systems, enhancing efficiency and reducing labor costs. Other types of diaphragm pumps, including those with specialized designs or materials, cater to niche applications where specific performance characteristics are required. For example, pumps made from advanced plastics or composites may be used in highly corrosive environments or where weight is a critical factor. The diversity of diaphragm pump designs ensures that there is a suitable option for virtually any application, contributing to the overall growth and dynamism of the global market. As industries continue to evolve and new challenges emerge, the demand for innovative and adaptable pumping solutions is likely to drive further advancements in diaphragm pump technology. Manufacturers are continually exploring new materials and designs to enhance the performance and durability of these pumps, ensuring they meet the ever-changing needs of their customers.

Water & Wastewater, Oil & Gas, Chemicals, Food & Beverages, Others in the Plastic Diaphragm Pumps - Global Market:

Plastic diaphragm pumps are extensively used across various industries due to their versatility and efficiency. In the water and wastewater sector, these pumps are essential for transferring and treating water, handling everything from clean water to sludge and slurry. Their ability to handle abrasive and corrosive fluids makes them ideal for this application, ensuring reliable performance even in challenging conditions. In the oil and gas industry, plastic diaphragm pumps are used for transferring fuels, chemicals, and other fluids, offering a safe and efficient solution for handling hazardous materials. Their robust construction and ability to operate in explosive environments make them a preferred choice in this sector. The chemical industry also relies heavily on plastic diaphragm pumps for transferring a wide range of chemicals, including acids, bases, and solvents. The pumps' resistance to corrosion and ability to handle aggressive fluids without degradation are key factors driving their adoption in this field. In the food and beverage industry, plastic diaphragm pumps are used for transferring ingredients, cleaning solutions, and finished products. Their hygienic design and ability to handle viscous and particulate-laden fluids make them suitable for this application, ensuring product quality and safety. Other industries, such as pharmaceuticals, mining, and construction, also benefit from the use of plastic diaphragm pumps, leveraging their adaptability and reliability to meet specific operational needs. The widespread use of these pumps across diverse sectors underscores their importance in modern industrial processes, highlighting the need for continued innovation and development to meet evolving market demands.

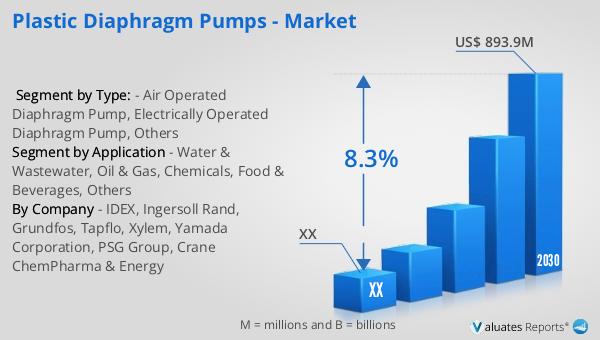

Plastic Diaphragm Pumps - Global Market Outlook:

The global market for plastic diaphragm pumps was valued at approximately $512 million in 2023 and is projected to grow significantly, reaching an estimated $893.9 million by 2030. This growth represents a compound annual growth rate (CAGR) of 8.3% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to see substantial growth, although specific figures were not provided. This expansion is driven by increasing demand across various industries, including water and wastewater, oil and gas, chemicals, and food and beverages. The versatility and efficiency of plastic diaphragm pumps make them an attractive option for companies seeking reliable and cost-effective fluid transfer solutions. As industries continue to prioritize sustainability and operational efficiency, the adoption of these pumps is likely to increase, further fueling market growth. The ongoing development of new materials and technologies is expected to enhance the performance and durability of plastic diaphragm pumps, ensuring they remain a vital component in industrial processes worldwide. This positive market outlook reflects the growing recognition of the benefits these pumps offer, positioning them as a key player in the global fluid handling industry.

| Report Metric | Details |

| Report Name | Plastic Diaphragm Pumps - Market |

| Forecasted market size in 2030 | US$ 893.9 million |

| CAGR | 8.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | IDEX, Ingersoll Rand, Grundfos, Tapflo, Xylem, Yamada Corporation, PSG Group, Crane ChemPharma & Energy |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |