What is Metallic Diaphragm Pump - Global Market?

Metallic diaphragm pumps are a crucial component in various industries due to their ability to handle a wide range of fluids, including those that are corrosive, viscous, or contain solids. These pumps operate using a flexible diaphragm made of metal, which is moved back and forth to create a pumping action. This design allows them to be highly durable and resistant to wear and tear, making them ideal for demanding applications. The global market for metallic diaphragm pumps is driven by their versatility and efficiency, as they can be used in numerous sectors such as water and wastewater treatment, oil and gas, chemicals, and food and beverages. Their ability to handle different types of fluids without contamination makes them particularly valuable in industries where purity is essential. Additionally, metallic diaphragm pumps are known for their reliability and low maintenance requirements, which further enhances their appeal in various industrial settings. As industries continue to seek efficient and reliable pumping solutions, the demand for metallic diaphragm pumps is expected to grow, reflecting their importance in the global market.

Air Operated, Electrically Operated, Others in the Metallic Diaphragm Pump - Global Market:

Metallic diaphragm pumps can be categorized based on their operation method, primarily into air-operated, electrically operated, and other types. Air-operated metallic diaphragm pumps are powered by compressed air, making them suitable for environments where electricity is not available or where there is a risk of explosion. These pumps are highly versatile and can handle a wide range of fluids, including those with high viscosity or containing solids. Their simple design and ease of maintenance make them a popular choice in industries such as mining, construction, and chemical processing. Electrically operated metallic diaphragm pumps, on the other hand, are powered by an electric motor. These pumps offer precise control over flow rates and are often used in applications where accuracy is crucial, such as in the pharmaceutical and food and beverage industries. They are also more energy-efficient compared to air-operated pumps, which can be a significant advantage in reducing operational costs. Other types of metallic diaphragm pumps include those that are hydraulically operated or use a combination of different power sources. These pumps are typically used in specialized applications where specific performance characteristics are required. For example, hydraulically operated pumps can provide higher pressure capabilities, making them suitable for applications such as high-pressure cleaning or in the oil and gas industry. The choice between these different types of metallic diaphragm pumps depends on various factors, including the specific requirements of the application, the type of fluid being pumped, and the operating environment. Each type of pump offers unique advantages and can be tailored to meet the needs of different industries. As technology continues to advance, the development of more efficient and versatile metallic diaphragm pumps is expected, further expanding their applications and market potential.

Water & Wastewater, Oil & Gas, Chemicals, Food & Beverages, Others in the Metallic Diaphragm Pump - Global Market:

Metallic diaphragm pumps are widely used across various industries due to their ability to handle diverse fluids and their robust construction. In the water and wastewater sector, these pumps are essential for transferring and treating water, as they can handle both clean and contaminated fluids without risk of leakage or contamination. Their durability and resistance to corrosive substances make them ideal for use in harsh environments, such as wastewater treatment plants. In the oil and gas industry, metallic diaphragm pumps are used for transferring crude oil, chemicals, and other fluids. Their ability to handle high-pressure applications and corrosive substances makes them a valuable asset in this sector. Additionally, their explosion-proof design ensures safety in hazardous environments. In the chemical industry, these pumps are used for transferring a wide range of chemicals, including acids, bases, and solvents. Their ability to handle aggressive and corrosive fluids without degradation makes them indispensable in chemical processing applications. In the food and beverage industry, metallic diaphragm pumps are used for transferring ingredients and finished products. Their sanitary design and ability to handle viscous fluids make them suitable for applications such as transferring syrups, sauces, and dairy products. Other industries that benefit from metallic diaphragm pumps include pharmaceuticals, mining, and construction. In pharmaceuticals, these pumps are used for transferring sensitive fluids without contamination, ensuring product purity and safety. In mining, they are used for dewatering and transferring slurry, while in construction, they are used for transferring concrete and other materials. The versatility and reliability of metallic diaphragm pumps make them a valuable tool in various industrial applications, contributing to their growing demand in the global market.

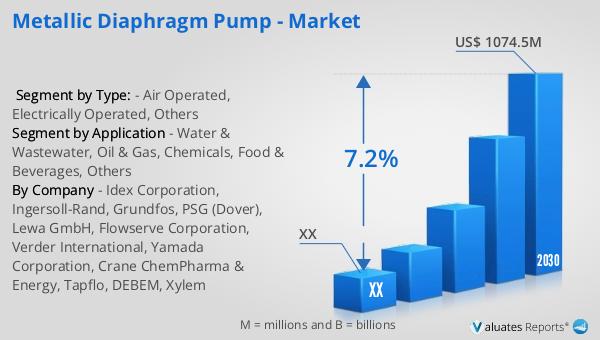

Metallic Diaphragm Pump - Global Market Outlook:

The global market for metallic diaphragm pumps was valued at approximately $687 million in 2023. It is projected to grow significantly, reaching an estimated size of $1,074.5 million by 2030, with a compound annual growth rate (CAGR) of 7.2% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for efficient and reliable pumping solutions across various industries. In North America, the market for metallic diaphragm pumps was valued at a substantial amount in 2023, and it is expected to continue its growth trajectory through 2030. The CAGR for this region during the forecast period is anticipated to be robust, indicating a strong market presence and potential for expansion. The growth in the North American market can be attributed to the region's well-established industrial base and the increasing adoption of advanced pumping technologies. As industries continue to seek efficient and cost-effective solutions for fluid transfer, the demand for metallic diaphragm pumps is expected to rise, driving market growth in both global and regional markets. The projected growth in the market underscores the importance of metallic diaphragm pumps as a critical component in various industrial applications, highlighting their role in enhancing operational efficiency and productivity.

| Report Metric | Details |

| Report Name | Metallic Diaphragm Pump - Market |

| Forecasted market size in 2030 | US$ 1074.5 million |

| CAGR | 7.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Idex Corporation, Ingersoll-Rand, Grundfos, PSG (Dover), Lewa GmbH, Flowserve Corporation, Verder International, Yamada Corporation, Crane ChemPharma & Energy, Tapflo, DEBEM, Xylem |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |