What is Transparent Thermoplastic Elastomers - Global Market?

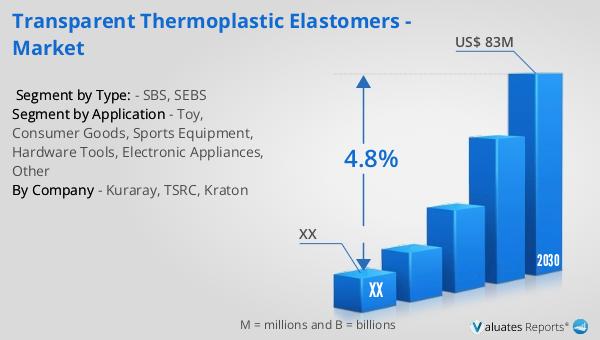

Transparent Thermoplastic Elastomers (TPEs) are a unique class of materials that combine the elastic properties of rubber with the processability of plastics. These materials are gaining significant traction in the global market due to their versatility and transparency, which make them suitable for a wide range of applications. TPEs are known for their flexibility, durability, and ability to be molded into various shapes, which makes them ideal for industries that require both aesthetic appeal and functional performance. The global market for Transparent Thermoplastic Elastomers was valued at approximately US$ 57 million in 2023, and it is projected to grow to US$ 83 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030. This growth is driven by increasing demand in sectors such as consumer goods, automotive, and electronics, where the need for lightweight, durable, and visually appealing materials is paramount. The North American market, in particular, is expected to see significant growth, contributing to the overall expansion of the global market. The adaptability of TPEs to various manufacturing processes, such as injection molding and extrusion, further enhances their appeal across different industries.

SBS, SEBS in the Transparent Thermoplastic Elastomers - Global Market:

Styrene-Butadiene-Styrene (SBS) and Styrene-Ethylene-Butylene-Styrene (SEBS) are two prominent types of Transparent Thermoplastic Elastomers that have carved out a significant niche in the global market. SBS is a block copolymer that combines the properties of rubber and plastic, offering excellent elasticity and processability. It is widely used in applications that require flexibility and resilience, such as footwear, adhesives, and sealants. SBS is particularly valued for its ability to be easily processed and its cost-effectiveness, making it a popular choice in industries where budget constraints are a consideration. On the other hand, SEBS is a hydrogenated version of SBS, which enhances its thermal stability and resistance to UV radiation and oxidation. This makes SEBS an ideal material for applications that require long-term durability and exposure to harsh environmental conditions. SEBS is commonly used in the automotive industry for interior components, as well as in medical devices and consumer electronics, where its superior performance characteristics are highly valued. The global market for SBS and SEBS is driven by their unique properties, which allow manufacturers to create products that meet specific performance and aesthetic requirements. The demand for these materials is expected to grow as industries continue to seek innovative solutions that combine functionality with visual appeal. The versatility of SBS and SEBS, coupled with their ability to be customized for specific applications, makes them indispensable in the development of new products and technologies. As the global market for Transparent Thermoplastic Elastomers continues to expand, SBS and SEBS are poised to play a crucial role in shaping the future of material science and engineering. Their ability to bridge the gap between traditional rubber and plastic materials offers manufacturers a unique opportunity to innovate and create products that meet the evolving needs of consumers and industries alike.

Toy, Consumer Goods, Sports Equipment, Hardware Tools, Electronic Appliances, Other in the Transparent Thermoplastic Elastomers - Global Market:

Transparent Thermoplastic Elastomers are increasingly being utilized across various sectors due to their unique properties and versatility. In the toy industry, TPEs are favored for their safety, flexibility, and ability to be molded into intricate shapes. These materials are non-toxic and hypoallergenic, making them ideal for children's toys that require both durability and safety. The transparency of TPEs also allows for the creation of visually appealing toys that can capture the attention of young consumers. In the realm of consumer goods, TPEs are used in products such as toothbrushes, kitchen utensils, and personal care items. Their soft-touch feel and resistance to wear and tear make them a preferred choice for products that require frequent handling and use. The sports equipment industry also benefits from the use of TPEs, as these materials provide the necessary flexibility and shock absorption needed for items like grips, handles, and protective gear. TPEs are also used in hardware tools, where their durability and resistance to chemicals and oils make them suitable for grips and handles that require a firm yet comfortable hold. In the electronics industry, TPEs are used in the production of flexible cables, connectors, and protective casings, where their insulating properties and resistance to environmental factors are crucial. Other applications of TPEs include medical devices, automotive components, and packaging materials, where their unique combination of properties offers manufacturers the ability to create innovative and functional products. The growing demand for Transparent Thermoplastic Elastomers in these sectors is a testament to their versatility and ability to meet the diverse needs of modern industries. As manufacturers continue to explore new applications and technologies, the use of TPEs is expected to expand, driving further growth in the global market.

Transparent Thermoplastic Elastomers - Global Market Outlook:

The global market for Transparent Thermoplastic Elastomers was valued at approximately US$ 57 million in 2023, with projections indicating a growth to US$ 83 million by 2030. This represents a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to contribute significantly to this growth, although specific figures for this region were not provided. The increasing demand for TPEs in various industries, including automotive, consumer goods, and electronics, is driving this market expansion. The versatility and unique properties of TPEs, such as their flexibility, durability, and transparency, make them an attractive choice for manufacturers looking to innovate and create products that meet the evolving needs of consumers. As industries continue to seek lightweight, durable, and visually appealing materials, the demand for Transparent Thermoplastic Elastomers is expected to rise, further fueling market growth. The adaptability of TPEs to various manufacturing processes, such as injection molding and extrusion, enhances their appeal across different sectors, contributing to the overall expansion of the global market.

| Report Metric | Details |

| Report Name | Transparent Thermoplastic Elastomers - Market |

| Forecasted market size in 2030 | US$ 83 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kuraray, TSRC, Kraton |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |