What is PET Crystalline and Non-crystalline Preform - Global Market?

PET Crystalline and Non-crystalline Preform - Global Market refers to the expansive industry surrounding the production and distribution of polyethylene terephthalate (PET) preforms, which are essential components in the manufacturing of plastic bottles and containers. PET preforms are small, test-tube-shaped pieces of plastic that are later blown into bottles or containers of various shapes and sizes. The market is divided into two main types: crystalline and non-crystalline preforms. Crystalline PET preforms are characterized by their structured molecular arrangement, which provides enhanced strength and thermal stability. This makes them suitable for applications requiring high durability and resistance to temperature variations. On the other hand, non-crystalline PET preforms have a more amorphous molecular structure, offering greater clarity and flexibility, which is ideal for products where visual appeal and versatility are prioritized. The global market for these preforms is driven by the increasing demand for lightweight, durable, and recyclable packaging solutions across various industries, including food and beverage, pharmaceuticals, and personal care. As environmental concerns and sustainability initiatives continue to grow, the PET preform market is expected to expand, with manufacturers focusing on innovative solutions to meet the evolving needs of consumers and industries worldwide.

Crystalline Preforms, Non-crystalline Preforms in the PET Crystalline and Non-crystalline Preform - Global Market:

Crystalline preforms, made from PET, are known for their robust structural integrity and thermal resistance, making them a preferred choice for packaging solutions that require durability and stability. These preforms undergo a process called crystallization, where the polymer chains are aligned in a highly ordered structure, resulting in a material that can withstand higher temperatures and mechanical stress. This characteristic makes crystalline preforms ideal for packaging carbonated beverages, as they can endure the pressure exerted by the carbonation without deforming or losing their shape. Additionally, crystalline preforms are often used in hot-fill applications, where the product is filled at high temperatures, necessitating a container that can maintain its form and protect the contents effectively. The clarity of crystalline preforms, although slightly less than their non-crystalline counterparts, is still sufficient for most applications, allowing consumers to view the product inside while ensuring its safety and integrity. Non-crystalline preforms, in contrast, are valued for their exceptional clarity and flexibility. The amorphous structure of non-crystalline PET allows for a high degree of transparency, making these preforms ideal for packaging products where visual appeal is crucial, such as juices and dairy products. The flexibility of non-crystalline preforms also allows for a wider range of design possibilities, enabling manufacturers to create unique and attractive packaging solutions that stand out on the shelves. Furthermore, non-crystalline preforms are often used in applications where the packaging needs to be lightweight and easy to handle, such as in the case of non-carbonated beverages. The versatility of non-crystalline preforms makes them a popular choice for a variety of industries, as they can be easily adapted to meet the specific requirements of different products and markets. The global market for PET crystalline and non-crystalline preforms is influenced by several factors, including technological advancements, consumer preferences, and regulatory changes. As technology continues to evolve, manufacturers are developing new methods to enhance the properties of PET preforms, such as improving their barrier properties to extend the shelf life of packaged products. Additionally, consumer preferences are shifting towards more sustainable and environmentally friendly packaging solutions, prompting manufacturers to explore the use of recycled PET and other eco-friendly materials in their preform production processes. Regulatory changes, particularly those related to environmental protection and waste management, are also impacting the market, as governments around the world implement stricter guidelines to reduce plastic waste and promote recycling. In conclusion, the PET crystalline and non-crystalline preform market is a dynamic and rapidly evolving industry, driven by the need for innovative and sustainable packaging solutions. As consumer demands and regulatory requirements continue to change, manufacturers must adapt and innovate to remain competitive in the global market. By focusing on the development of new technologies and materials, as well as exploring opportunities for recycling and sustainability, the PET preform industry is poised for continued growth and success in the coming years.

Carbonated and Non-carbonated Beverages, Dairy Products, Juices in the PET Crystalline and Non-crystalline Preform - Global Market:

The usage of PET crystalline and non-crystalline preforms in the global market is particularly significant in the packaging of carbonated and non-carbonated beverages, dairy products, and juices. In the realm of carbonated beverages, crystalline PET preforms are the preferred choice due to their ability to withstand the internal pressure exerted by carbonation. The structural integrity and thermal resistance of crystalline preforms ensure that the bottles maintain their shape and do not burst or deform, even when subjected to high pressure. This makes them ideal for packaging sodas, sparkling water, and other carbonated drinks, where maintaining the integrity of the packaging is crucial for preserving the quality and safety of the product. For non-carbonated beverages, such as still water, iced tea, and sports drinks, non-crystalline PET preforms are often used. The clarity and flexibility of non-crystalline preforms make them an attractive option for these products, as they allow for a wide range of design possibilities and provide a clear view of the contents inside. This is particularly important for non-carbonated beverages, where the visual appeal of the packaging can significantly influence consumer purchasing decisions. Additionally, the lightweight nature of non-crystalline preforms makes them easy to handle and transport, reducing shipping costs and improving overall efficiency in the supply chain. In the dairy industry, PET preforms are used to package a variety of products, including milk, yogurt, and cream. The choice between crystalline and non-crystalline preforms depends on the specific requirements of the product. For instance, products that require pasteurization or are filled at high temperatures may benefit from the use of crystalline preforms, which can withstand the heat without compromising the integrity of the packaging. On the other hand, non-crystalline preforms may be preferred for products that are sensitive to light and require a high degree of clarity to showcase their freshness and quality. Juices, both fruit and vegetable, are another major application area for PET preforms. The transparency and flexibility of non-crystalline preforms make them an ideal choice for juice packaging, as they allow consumers to see the vibrant colors of the juice inside, enhancing the product's visual appeal. Moreover, the ability to mold non-crystalline preforms into various shapes and sizes enables manufacturers to create unique and eye-catching packaging designs that stand out on the shelves. This is particularly important in the competitive juice market, where differentiation and branding play a crucial role in attracting consumers. Overall, the use of PET crystalline and non-crystalline preforms in the packaging of carbonated and non-carbonated beverages, dairy products, and juices highlights the versatility and adaptability of these materials. As consumer preferences continue to evolve and the demand for sustainable packaging solutions grows, the PET preform market is expected to expand, with manufacturers focusing on developing innovative and eco-friendly packaging options to meet the needs of various industries.

PET Crystalline and Non-crystalline Preform - Global Market Outlook:

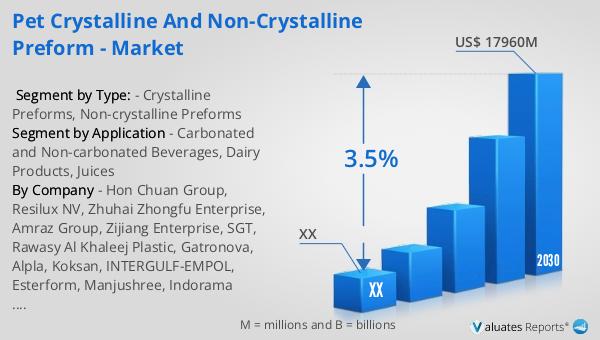

The global market outlook for PET crystalline and non-crystalline preforms indicates a promising future, with significant growth anticipated over the coming years. In 2023, the market was valued at approximately US$ 14,500 million, reflecting the widespread demand for PET preforms across various industries. This demand is driven by the increasing need for lightweight, durable, and recyclable packaging solutions, as well as the growing emphasis on sustainability and environmental responsibility. As industries continue to seek out innovative packaging options that align with these values, the market for PET preforms is expected to expand further. By 2030, the market is projected to reach a readjusted size of US$ 17,960 million, with a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2024 to 2030. This growth can be attributed to several factors, including advancements in PET preform manufacturing technologies, the development of new materials and formulations, and the increasing adoption of recycled PET in preform production. Additionally, the rising demand for packaged beverages, dairy products, and juices, particularly in emerging markets, is expected to contribute to the market's expansion. As the market continues to evolve, manufacturers are likely to focus on enhancing the properties of PET preforms, such as improving their barrier properties, reducing their environmental impact, and increasing their recyclability. By doing so, they can better meet the needs of consumers and industries, while also addressing the growing concerns surrounding plastic waste and sustainability. Overall, the global market outlook for PET crystalline and non-crystalline preforms is positive, with significant opportunities for growth and innovation in the years to come.

| Report Metric | Details |

| Report Name | PET Crystalline and Non-crystalline Preform - Market |

| Forecasted market size in 2030 | US$ 17960 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hon Chuan Group, Resilux NV, Zhuhai Zhongfu Enterprise, Amraz Group, Zijiang Enterprise, SGT, Rawasy Al Khaleej Plastic, Gatronova, Alpla, Koksan, INTERGULF-EMPOL, Esterform, Manjushree, Indorama Ventures Public Company, GTX HANEX Plastic, Ultrapak, Nuovaplast, Abottle, Zhenghao Plastic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |