What is Polyethylene Powder Coating - Global Market?

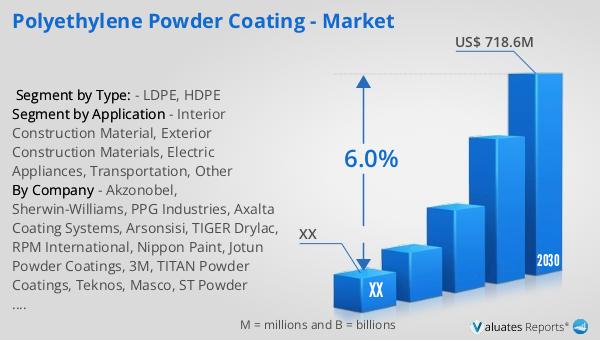

Polyethylene powder coating is a specialized process used in various industries to provide a durable and protective finish to surfaces. This type of coating is made from polyethylene, a versatile plastic known for its strength and flexibility. The global market for polyethylene powder coating is expanding due to its numerous advantages, such as excellent adhesion, corrosion resistance, and abrasion resistance. These properties make it an ideal choice for applications where durability and longevity are crucial. The process involves applying a fine powder to a surface, which is then heated to form a smooth, hard coating. This method is environmentally friendly as it produces minimal waste and does not require solvents. The market for polyethylene powder coating was valued at approximately US$ 476.1 million in 2023 and is projected to grow significantly, reaching an estimated US$ 718.6 million by 2030. This growth is driven by increasing demand in sectors such as construction, automotive, and electronics, where the need for protective coatings is paramount. The compound annual growth rate (CAGR) of 6.0% during the forecast period from 2024 to 2030 highlights the rising importance and adoption of polyethylene powder coatings across various industries worldwide.

LDPE, HDPE in the Polyethylene Powder Coating - Global Market:

Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) are two primary types of polyethylene used in powder coatings, each offering distinct properties that cater to different applications. LDPE is known for its flexibility and toughness, making it suitable for applications where a softer, more pliable coating is needed. It is often used in situations where impact resistance is crucial, such as in protective coatings for pipes and fittings. LDPE coatings provide a smooth finish and are resistant to chemicals and moisture, making them ideal for both indoor and outdoor applications. On the other hand, HDPE is characterized by its high strength-to-density ratio, offering a more rigid and durable coating. This makes HDPE suitable for applications requiring a hard, wear-resistant surface, such as in automotive parts and heavy machinery. HDPE coatings are also highly resistant to abrasion and can withstand harsh environmental conditions, making them a preferred choice for outdoor applications. The global market for polyethylene powder coatings is witnessing a growing demand for both LDPE and HDPE coatings due to their unique properties and wide range of applications. In the construction industry, LDPE coatings are often used for interior applications where flexibility and impact resistance are needed, while HDPE coatings are preferred for exterior applications due to their durability and weather resistance. In the electronics industry, LDPE coatings are used to protect delicate components from moisture and chemicals, while HDPE coatings provide a hard, protective layer for more robust components. The transportation sector also benefits from both types of coatings, with LDPE providing a flexible, protective layer for interior components and HDPE offering a durable, wear-resistant surface for exterior parts. The versatility of LDPE and HDPE coatings makes them an essential component in the global polyethylene powder coating market, catering to a wide range of industries and applications. As the demand for durable and environmentally friendly coatings continues to rise, the market for LDPE and HDPE powder coatings is expected to grow, driven by advancements in technology and increasing awareness of the benefits of polyethylene coatings.

Interior Construction Material, Exterior Construction Materials, Electric Appliances, Transportation, Other in the Polyethylene Powder Coating - Global Market:

Polyethylene powder coatings are extensively used in various sectors due to their durability and protective qualities. In the realm of interior construction materials, these coatings are applied to surfaces like metal fixtures, furniture, and fittings to enhance their longevity and resistance to wear and tear. The flexibility of polyethylene coatings, particularly those made from LDPE, allows them to absorb impacts and resist scratches, making them ideal for high-traffic areas within buildings. For exterior construction materials, HDPE-based polyethylene coatings are favored for their robustness and ability to withstand harsh weather conditions. These coatings are applied to outdoor structures, such as railings, fences, and building facades, providing a protective barrier against corrosion and UV radiation. This not only extends the lifespan of the materials but also maintains their aesthetic appeal over time. In the electric appliances sector, polyethylene powder coatings are used to protect components from moisture, chemicals, and electrical interference. LDPE coatings are often applied to delicate parts to prevent damage, while HDPE coatings provide a hard, protective layer for more robust components. This ensures the reliability and efficiency of appliances, contributing to their overall performance and longevity. The transportation industry also benefits from the use of polyethylene powder coatings, with applications ranging from automotive parts to public transportation vehicles. LDPE coatings offer flexibility and impact resistance for interior components, such as dashboards and door panels, while HDPE coatings provide a durable, wear-resistant surface for exterior parts, such as bumpers and body panels. This enhances the safety and durability of vehicles, reducing maintenance costs and extending their service life. Beyond these sectors, polyethylene powder coatings are also used in various other applications, including agricultural equipment, industrial machinery, and consumer goods. The versatility and protective qualities of these coatings make them an essential component in many industries, driving their demand in the global market. As awareness of the benefits of polyethylene powder coatings continues to grow, their usage is expected to expand across different sectors, contributing to the overall growth of the market.

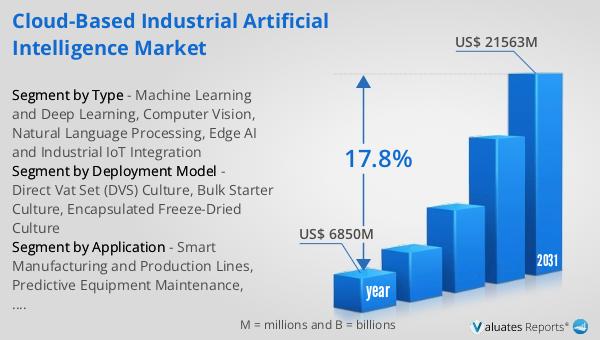

Polyethylene Powder Coating - Global Market Outlook:

The global market for polyethylene powder coating was valued at approximately US$ 476.1 million in 2023, and it is anticipated to grow to a revised size of US$ 718.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.0% during the forecast period from 2024 to 2030. This growth is driven by the numerous advantages offered by polyethylene powder coatings, including excellent adhesion, corrosion resistance, and abrasion resistance. These properties make them an ideal choice for a wide range of applications, from construction and automotive to electronics and consumer goods. The ability of polyethylene powder coatings to provide a durable and protective finish to surfaces is a key factor contributing to their increasing demand in the global market. Additionally, the environmentally friendly nature of the powder coating process, which produces minimal waste and does not require solvents, is further boosting its popularity among industries seeking sustainable solutions. As the market continues to expand, advancements in technology and increasing awareness of the benefits of polyethylene powder coatings are expected to drive further growth, making them an essential component in various industries worldwide.

| Report Metric | Details |

| Report Name | Polyethylene Powder Coating - Market |

| Forecasted market size in 2030 | US$ 718.6 million |

| CAGR | 6.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Akzonobel, Sherwin-Williams, PPG Industries, Axalta Coating Systems, Arsonsisi, TIGER Drylac, RPM International, Nippon Paint, Jotun Powder Coatings, 3M, TITAN Powder Coatings, Teknos, Masco, ST Powder Coatings, Ripol, RIH, Pulverit, Protech-Oxyplast, American Powder Coatings, IGP, CIN, ADAPTA COLOR, Aiyue Group, Huangshan Huajia Surface Technology, Kim Goryeo Group, Guangdong Wisdom Environmental Protection Technology, Fujian Wan'an, Anhui Meijia New Material, Zhejiang Huacai New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |