What is Polyester Powder Coating - Global Market?

Polyester powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike traditional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat. This process allows the powder to form a "skin," creating a hard finish that is tougher than conventional paint. The global market for polyester powder coating is experiencing significant growth due to its durability, environmental benefits, and cost-effectiveness. Polyester powder coatings are widely used in various industries, including automotive, construction, and consumer goods, due to their excellent weather resistance, color retention, and gloss. They are particularly favored for outdoor applications where UV stability and resistance to weathering are crucial. The market is driven by increasing demand for eco-friendly coating solutions, as polyester powder coatings contain no solvents and release negligible amounts of volatile organic compounds (VOCs) into the atmosphere. This makes them an attractive option for companies looking to reduce their environmental footprint. Additionally, advancements in technology have led to the development of new formulations that offer enhanced performance characteristics, further boosting the market's growth prospects.

TGIC, non-TGIC in the Polyester Powder Coating - Global Market:

TGIC (triglycidyl isocyanurate) and non-TGIC polyester powder coatings are two primary types of polyester powder coatings used in various applications. TGIC-based polyester powder coatings are known for their excellent weather resistance, mechanical properties, and chemical resistance. They are widely used in outdoor applications such as architectural aluminum, automotive parts, and outdoor furniture due to their ability to withstand harsh environmental conditions. TGIC acts as a cross-linking agent, providing the coating with superior durability and flexibility. However, concerns over the potential health risks associated with TGIC have led to the development of non-TGIC alternatives. Non-TGIC polyester powder coatings use alternative cross-linking agents, such as HAA (β-hydroxyalkylamide), which offer similar performance characteristics without the associated health risks. These coatings are gaining popularity in regions with stringent environmental regulations, as they provide a safer and more sustainable option. The global market for TGIC and non-TGIC polyester powder coatings is influenced by factors such as regulatory changes, technological advancements, and shifting consumer preferences. As industries continue to seek environmentally friendly and high-performance coating solutions, the demand for both TGIC and non-TGIC polyester powder coatings is expected to grow. Manufacturers are investing in research and development to improve the performance and sustainability of these coatings, ensuring they meet the evolving needs of various industries. The choice between TGIC and non-TGIC coatings often depends on specific application requirements, regulatory compliance, and cost considerations. While TGIC-based coatings remain popular for their proven performance, non-TGIC alternatives are increasingly being adopted in markets where health and environmental concerns are paramount. This shift is driving innovation in the industry, with companies exploring new formulations and technologies to enhance the properties of non-TGIC coatings. As a result, the global market for polyester powder coatings is becoming more diverse, offering a wide range of options to meet the needs of different applications and industries.

Interior Construction Material, Exterior Construction Materials, Electric Appliances, Transportation, Other in the Polyester Powder Coating - Global Market:

Polyester powder coatings are extensively used in various sectors, including interior and exterior construction materials, electric appliances, transportation, and other industries. In the realm of interior construction materials, polyester powder coatings are applied to metal fixtures, furniture, and decorative elements. Their durability and aesthetic appeal make them ideal for use in high-traffic areas, where surfaces are prone to wear and tear. The coatings provide a smooth, attractive finish that enhances the visual appeal of interior spaces while offering protection against scratches and corrosion. For exterior construction materials, polyester powder coatings are favored for their excellent weather resistance and UV stability. They are commonly used on architectural aluminum, steel structures, and outdoor furniture, where they provide long-lasting protection against the elements. The coatings help maintain the structural integrity and appearance of buildings and outdoor installations, reducing maintenance costs and extending the lifespan of the materials. In the electric appliances sector, polyester powder coatings are used to coat the surfaces of appliances such as refrigerators, washing machines, and ovens. The coatings provide a durable, easy-to-clean finish that enhances the appearance and longevity of the appliances. They also offer excellent resistance to heat, chemicals, and abrasion, making them suitable for use in demanding environments. In the transportation industry, polyester powder coatings are applied to automotive parts, bicycles, and other vehicles. Their robust protective properties help prevent corrosion and damage from road debris, ensuring the longevity and performance of the coated components. The coatings also contribute to the aesthetic appeal of vehicles, offering a wide range of colors and finishes to suit different design preferences. Beyond these specific applications, polyester powder coatings are used in various other industries, including consumer goods, industrial equipment, and agricultural machinery. Their versatility, durability, and environmental benefits make them a popular choice for manufacturers seeking high-performance coating solutions. As the demand for sustainable and efficient coatings continues to grow, the use of polyester powder coatings in these diverse applications is expected to increase, driving further innovation and development in the market.

Polyester Powder Coating - Global Market Outlook:

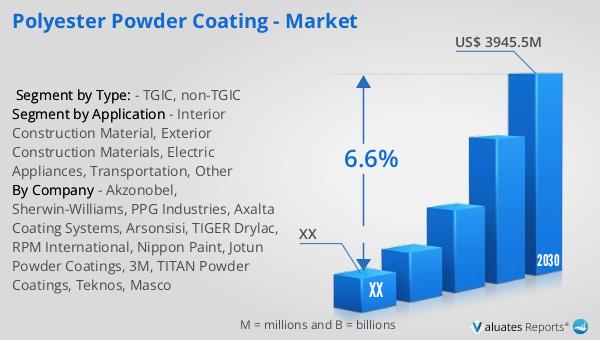

The global market for polyester powder coating was valued at approximately $2,527.2 million in 2023. It is projected to expand to a revised size of around $3,945.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for durable, environmentally friendly coating solutions across various industries. The North American market for polyester powder coating, although not specified in exact figures, is also expected to experience growth during this period. The market dynamics in North America will be influenced by factors such as technological advancements, regulatory changes, and shifting consumer preferences towards sustainable products. As industries continue to prioritize eco-friendly and high-performance coatings, the demand for polyester powder coatings is likely to rise, contributing to the overall growth of the market. This positive outlook underscores the importance of polyester powder coatings in meeting the evolving needs of industries seeking durable and sustainable coating solutions.

| Report Metric | Details |

| Report Name | Polyester Powder Coating - Market |

| Forecasted market size in 2030 | US$ 3945.5 million |

| CAGR | 6.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Akzonobel, Sherwin-Williams, PPG Industries, Axalta Coating Systems, Arsonsisi, TIGER Drylac, RPM International, Nippon Paint, Jotun Powder Coatings, 3M, TITAN Powder Coatings, Teknos, Masco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |