What is Industrial Floor Hardener - Global Market?

Industrial floor hardeners are specialized materials used to enhance the durability and longevity of concrete floors in industrial settings. These hardeners are applied to the surface of concrete floors to increase their resistance to wear, abrasion, and chemical damage, making them ideal for environments that experience heavy foot and machinery traffic. The global market for industrial floor hardeners is driven by the growing demand for durable flooring solutions in various industries such as manufacturing, warehousing, and logistics. As industries continue to expand and modernize, the need for robust flooring systems that can withstand harsh conditions becomes increasingly important. Industrial floor hardeners are available in various forms, including dry shake, liquid, and powder, each offering unique benefits and applications. The market is characterized by a wide range of products tailored to meet specific industrial requirements, ensuring that businesses can find the right solution for their flooring needs. With advancements in technology and materials, the industrial floor hardener market is poised for continued growth, offering innovative solutions that enhance the performance and lifespan of concrete floors.

Natural Quartz Aggregate, Synthetic (Non-metallic) Mineral Aggregates, Metallic and Metallic Alloy Aggregates in the Industrial Floor Hardener - Global Market:

Natural quartz aggregate is a popular choice in the industrial floor hardener market due to its exceptional hardness and durability. Quartz is a naturally occurring mineral that is highly resistant to wear and abrasion, making it ideal for use in environments that experience heavy traffic and mechanical stress. When used as an aggregate in floor hardeners, quartz provides a tough, long-lasting surface that can withstand the rigors of industrial operations. Its natural properties also make it resistant to chemical attacks, ensuring that floors remain intact even in harsh chemical environments. Synthetic (non-metallic) mineral aggregates are another option in the industrial floor hardener market. These aggregates are engineered to provide specific performance characteristics, such as enhanced strength, durability, and resistance to environmental factors. They are often used in applications where natural aggregates may not meet the required specifications or where additional properties are desired. Synthetic aggregates can be tailored to meet the unique needs of different industries, offering a versatile solution for industrial flooring. Metallic and metallic alloy aggregates are also used in industrial floor hardeners, providing a unique set of benefits. These aggregates are typically made from materials such as iron, steel, or aluminum, and are known for their exceptional strength and durability. Metallic aggregates are often used in environments that require floors to withstand extreme mechanical stress, such as heavy machinery operations or high-impact areas. They offer superior resistance to wear and abrasion, ensuring that floors remain intact even under the most demanding conditions. Additionally, metallic aggregates can provide enhanced thermal conductivity, making them suitable for use in environments where temperature regulation is important. The choice of aggregate in industrial floor hardeners depends on the specific requirements of the application, with each type offering distinct advantages that cater to different industrial needs.

Factory Workshop, Parking Lot, Warehouse, Others in the Industrial Floor Hardener - Global Market:

Industrial floor hardeners are widely used in various areas, including factory workshops, parking lots, warehouses, and other industrial settings. In factory workshops, these hardeners are essential for creating durable and resilient flooring that can withstand the constant movement of heavy machinery and equipment. The enhanced wear resistance provided by industrial floor hardeners ensures that floors remain intact and functional, even in high-traffic areas. This durability reduces the need for frequent repairs and maintenance, ultimately saving businesses time and money. In parking lots, industrial floor hardeners are used to create surfaces that can endure the weight and movement of vehicles. The increased abrasion resistance offered by these hardeners helps prevent surface damage caused by tire friction and environmental factors, such as rain and temperature fluctuations. This results in longer-lasting parking surfaces that require less maintenance and repair. Warehouses also benefit from the use of industrial floor hardeners, as they provide a robust flooring solution that can support the weight of stored goods and the movement of forklifts and other equipment. The enhanced durability and resistance to wear and tear ensure that warehouse floors remain in good condition, even under heavy loads. This is particularly important in logistics and distribution centers, where efficient operations depend on the integrity of the flooring. Other industrial settings, such as manufacturing plants and distribution centers, also utilize industrial floor hardeners to create durable and reliable flooring solutions. These hardeners help protect floors from the wear and tear associated with daily operations, ensuring that they remain functional and safe for workers. By providing a strong and resilient surface, industrial floor hardeners contribute to the overall efficiency and productivity of industrial facilities.

Industrial Floor Hardener - Global Market Outlook:

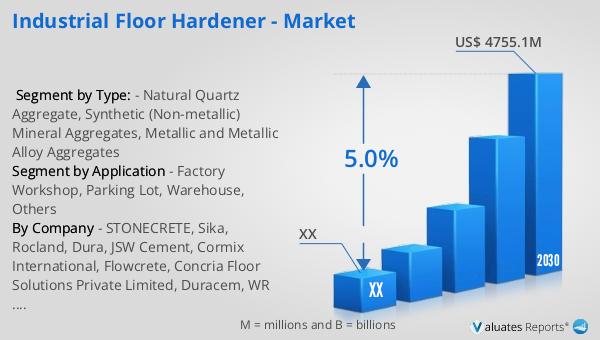

In 2023, the global market for industrial floor hardeners was valued at approximately $3.5 billion. Looking ahead, this market is projected to grow, reaching an estimated value of $4.755 billion by 2030. This growth represents a compound annual growth rate (CAGR) of 5.0% over the forecast period from 2024 to 2030. The increasing demand for durable and long-lasting flooring solutions in various industrial sectors is a key driver of this market expansion. As industries continue to evolve and modernize, the need for flooring systems that can withstand harsh conditions and heavy usage becomes more critical. Industrial floor hardeners offer a solution to these challenges, providing enhanced durability and resistance to wear and tear. The market's growth is also supported by advancements in technology and materials, which have led to the development of innovative products that meet the specific needs of different industries. As a result, businesses are increasingly investing in industrial floor hardeners to improve the performance and longevity of their flooring systems. This trend is expected to continue, driving further growth in the global market for industrial floor hardeners.

| Report Metric | Details |

| Report Name | Industrial Floor Hardener - Market |

| Forecasted market size in 2030 | US$ 4755.1 million |

| CAGR | 5.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | STONECRETE, Sika, Rocland, Dura, JSW Cement, Cormix International, Flowcrete, Concria Floor Solutions Private Limited, Duracem, WR MEADOWS, INC., Chemind Industries Sdn Bhd, Master Builders Solutions, ConTech Chemicals, LATICRETE, Fountech, Euclid Chemical Company, MCON RASAYAN, ISOMAT, LITOKE, Shenzhen Zhongrunchang Industrial Flooring |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |