What is Residue Hydrodesulfurization Catalysts - Global Market?

Residue hydrodesulfurization catalysts play a crucial role in the global market by facilitating the removal of sulfur from petroleum products. This process is essential because sulfur compounds in fuels can lead to harmful emissions when burned, contributing to air pollution and acid rain. The catalysts work by promoting a chemical reaction that converts sulfur compounds into hydrogen sulfide, a gas that can be easily separated from the hydrocarbon stream. This transformation is vital for meeting stringent environmental regulations and producing cleaner fuels. The global market for these catalysts is driven by the increasing demand for low-sulfur fuels and the need to comply with environmental standards. As refineries strive to produce cleaner products, the demand for effective hydrodesulfurization catalysts continues to grow. The market is characterized by technological advancements and innovations aimed at improving the efficiency and effectiveness of these catalysts, ensuring they can handle the complex feedstocks and stringent requirements of modern refineries. The ongoing research and development in this field are expected to further enhance the capabilities of these catalysts, making them indispensable in the quest for cleaner energy solutions.

Nickel-Tungsten, Nickel-Molybdenum, Cobalt-Molybdenum, Other in the Residue Hydrodesulfurization Catalysts - Global Market:

Nickel-tungsten, nickel-molybdenum, cobalt-molybdenum, and other catalysts are integral to the residue hydrodesulfurization process, each offering unique properties and benefits. Nickel-tungsten catalysts are known for their high activity and stability, making them suitable for processing heavy feedstocks with high sulfur content. These catalysts are particularly effective in breaking down complex sulfur compounds, ensuring efficient sulfur removal. Nickel-molybdenum catalysts, on the other hand, are widely used due to their cost-effectiveness and versatility. They offer a good balance between activity and selectivity, making them suitable for a range of feedstocks. These catalysts are often used in combination with other metals to enhance their performance and extend their lifespan. Cobalt-molybdenum catalysts are favored for their ability to operate at lower temperatures, reducing energy consumption and operational costs. They are particularly effective in treating lighter feedstocks and are often used in conjunction with nickel-based catalysts to achieve optimal results. Other catalysts, including those based on rare earth metals and novel formulations, are being developed to address specific challenges in the hydrodesulfurization process. These catalysts aim to improve the efficiency of sulfur removal while minimizing the formation of undesirable by-products. The choice of catalyst depends on various factors, including the type of feedstock, operating conditions, and desired product specifications. As refineries face increasing pressure to produce cleaner fuels, the demand for advanced catalysts that can meet these requirements is expected to rise. The development of new catalyst formulations and technologies is crucial for enhancing the efficiency and effectiveness of the hydrodesulfurization process, ensuring that refineries can meet the evolving demands of the market.

Atmospheric Residue, Vacuum Residue in the Residue Hydrodesulfurization Catalysts - Global Market:

Residue hydrodesulfurization catalysts are extensively used in processing atmospheric and vacuum residues, which are the heavier fractions of crude oil. Atmospheric residue, also known as atmospheric distillation bottoms, is the residue left after the initial distillation of crude oil. It contains a high concentration of sulfur compounds, making it a challenging feedstock for refineries. Hydrodesulfurization catalysts are employed to break down these sulfur compounds, converting them into hydrogen sulfide gas that can be easily removed. This process is essential for producing low-sulfur fuels and meeting environmental regulations. Vacuum residue, on the other hand, is the heaviest fraction obtained from the vacuum distillation of crude oil. It contains even higher levels of sulfur and other impurities, requiring more robust catalysts for effective processing. The use of hydrodesulfurization catalysts in vacuum residue processing is crucial for reducing sulfur content and improving the quality of the final products. These catalysts help in breaking down complex sulfur compounds, ensuring efficient sulfur removal and enhancing the overall efficiency of the refining process. The choice of catalyst for processing atmospheric and vacuum residues depends on various factors, including the type of feedstock, operating conditions, and desired product specifications. Advanced catalysts are being developed to address the specific challenges associated with processing these heavy residues, ensuring that refineries can produce cleaner fuels and meet stringent environmental standards. The ongoing research and development in this field are expected to further enhance the capabilities of these catalysts, making them indispensable in the quest for cleaner energy solutions.

Residue Hydrodesulfurization Catalysts - Global Market Outlook:

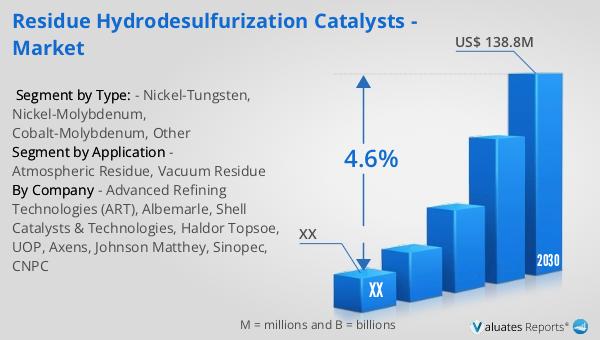

The global market for residue hydrodesulfurization catalysts was valued at approximately $101 million in 2023, with projections indicating a growth to around $138.8 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.6% from 2024 to 2030. These catalysts are essential in facilitating the chemical reaction that transforms sulfur compounds into hydrogen sulfide, a gas that can be easily separated from the hydrocarbon stream. This process is crucial for producing low-sulfur fuels and meeting environmental regulations. The increasing demand for cleaner fuels and the need to comply with stringent environmental standards are driving the growth of the residue hydrodesulfurization catalysts market. As refineries strive to produce cleaner products, the demand for effective catalysts continues to rise. The market is characterized by technological advancements and innovations aimed at improving the efficiency and effectiveness of these catalysts, ensuring they can handle the complex feedstocks and stringent requirements of modern refineries. The ongoing research and development in this field are expected to further enhance the capabilities of these catalysts, making them indispensable in the quest for cleaner energy solutions.

| Report Metric | Details |

| Report Name | Residue Hydrodesulfurization Catalysts - Market |

| Forecasted market size in 2030 | US$ 138.8 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Advanced Refining Technologies (ART), Albemarle, Shell Catalysts & Technologies, Haldor Topsoe, UOP, Axens, Johnson Matthey, Sinopec, CNPC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |