What is Transparent PET Preform - Global Market?

Transparent PET preforms are a crucial component in the packaging industry, serving as the initial form from which PET bottles are blown. These preforms are made from polyethylene terephthalate (PET), a type of plastic known for its strength, transparency, and lightweight properties. The global market for transparent PET preforms is driven by their widespread use in various industries, including beverages, food, cosmetics, and pharmaceuticals. The demand for these preforms is increasing due to their recyclability and the growing consumer preference for sustainable packaging solutions. Additionally, the versatility of PET preforms allows manufacturers to produce bottles of different shapes and sizes, catering to diverse market needs. The market is also influenced by technological advancements that enhance the quality and efficiency of PET preform production. As industries continue to seek eco-friendly and cost-effective packaging options, the transparent PET preform market is expected to grow, adapting to the evolving demands of both manufacturers and consumers.

Cold Fill Preform, Hot Fill Preform in the Transparent PET Preform - Global Market:

Cold fill and hot fill preforms are two distinct types of transparent PET preforms used in the packaging industry, each catering to specific product requirements. Cold fill preforms are primarily used for packaging products that do not require pasteurization or sterilization, such as carbonated beverages and certain non-carbonated drinks. These preforms are designed to withstand the pressure of carbonated liquids, ensuring that the final bottle maintains its shape and integrity. The cold fill process involves filling the bottle at ambient temperatures, which helps preserve the taste and nutritional value of the product. On the other hand, hot fill preforms are used for products that require sterilization, such as juices, liquid dairy products, and some non-carbonated beverages. The hot fill process involves heating the product to a high temperature to kill bacteria and then filling it into the bottle while still hot. This method extends the shelf life of the product without the need for preservatives. Hot fill preforms are designed to withstand the thermal stress of the filling process, ensuring that the bottle does not deform or lose its clarity. Both cold fill and hot fill preforms are made from PET, which offers excellent barrier properties, protecting the contents from external factors such as oxygen and moisture. The choice between cold fill and hot fill preforms depends on the specific requirements of the product being packaged, including its shelf life, taste, and nutritional content. Manufacturers must carefully consider these factors when selecting the appropriate preform type to ensure product quality and consumer satisfaction. As the global market for transparent PET preforms continues to grow, advancements in technology and materials are expected to further enhance the performance and versatility of both cold fill and hot fill preforms, meeting the diverse needs of the packaging industry.

Carbonated and Non-carbonated Beverages, Liquid Dairy Products and Juices, Oil, Industrial Fluids, Cosmetics, Others in the Transparent PET Preform - Global Market:

Transparent PET preforms are widely used in the packaging of carbonated and non-carbonated beverages, liquid dairy products, juices, oils, industrial fluids, cosmetics, and other products. In the beverage industry, PET preforms are favored for their ability to maintain the carbonation and freshness of drinks, making them ideal for packaging sodas, sparkling water, and energy drinks. For non-carbonated beverages like iced tea, sports drinks, and flavored water, PET preforms offer a lightweight and shatterproof alternative to glass, ensuring safety and convenience for consumers. In the dairy sector, PET preforms are used to package milk, yogurt drinks, and other liquid dairy products, providing a hygienic and durable solution that extends the shelf life of these perishable items. Juices, which often require pasteurization, benefit from the use of hot fill PET preforms, which can withstand the high temperatures of the filling process without compromising the bottle's integrity. The oil industry also relies on PET preforms for packaging cooking oils, lubricants, and other industrial fluids, as they offer excellent chemical resistance and prevent leakage. In the cosmetics industry, PET preforms are used to create bottles for shampoos, conditioners, lotions, and other personal care products, offering a clear and attractive packaging solution that enhances product visibility on store shelves. Additionally, PET preforms are used in various other applications, such as household cleaning products and pharmaceuticals, due to their versatility and cost-effectiveness. As consumer demand for sustainable and convenient packaging continues to rise, the use of transparent PET preforms in these diverse sectors is expected to grow, driven by their ability to meet the functional and aesthetic needs of modern packaging.

Transparent PET Preform - Global Market Outlook:

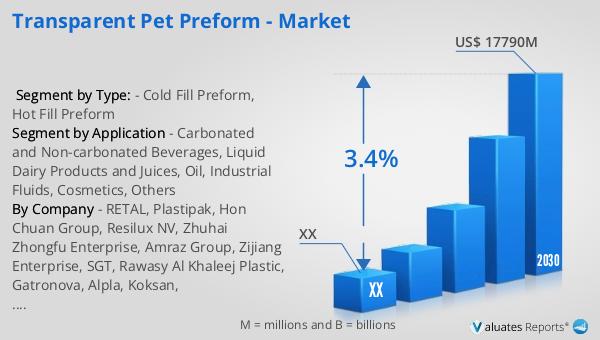

The global market for transparent PET preforms was valued at approximately $14,480 million in 2023. This market is projected to expand to a revised size of around $17,790 million by the year 2030, reflecting a compound annual growth rate (CAGR) of 3.4% over the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for PET preforms across various industries, driven by their advantageous properties such as durability, transparency, and recyclability. The market's expansion is also supported by the rising consumer preference for sustainable packaging solutions, as PET preforms are known for their eco-friendly characteristics. Additionally, the versatility of PET preforms in accommodating different product types and packaging requirements contributes to their growing popularity. As industries continue to innovate and adapt to changing consumer preferences, the transparent PET preform market is poised for steady growth, offering opportunities for manufacturers to capitalize on the increasing demand for efficient and sustainable packaging solutions. The projected growth of this market underscores the importance of PET preforms in the global packaging landscape, highlighting their role in meeting the evolving needs of both manufacturers and consumers.

| Report Metric | Details |

| Report Name | Transparent PET Preform - Market |

| Forecasted market size in 2030 | US$ 17790 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | RETAL, Plastipak, Hon Chuan Group, Resilux NV, Zhuhai Zhongfu Enterprise, Amraz Group, Zijiang Enterprise, SGT, Rawasy Al Khaleej Plastic, Gatronova, Alpla, Koksan, INTERGULF-EMPOL, Esterform, Manjushree, Indorama Ventures Public Company, GTX HANEX Plastic, Ultrapak, Nuovaplast, Putoksnis, Constar Plastics, Caiba, ETALON, SNJ Synthetics, EcoPack, Ahimsa Industries Limited, Abottle, Zhenghao Plastic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |