What is Global Downdraft Extraction Bench Market?

The Global Downdraft Extraction Bench Market is a specialized segment within the broader industrial equipment market, focusing on workbenches equipped with downdraft ventilation systems. These benches are designed to capture and filter dust, fumes, and other airborne contaminants directly at the work surface, ensuring a cleaner and safer working environment. They are widely used in various industries such as manufacturing, automotive, pharmaceutical, and military, where maintaining air quality is crucial for both worker safety and product integrity. The market for these benches is driven by increasing awareness of occupational health and safety standards, as well as stringent regulations aimed at reducing workplace hazards. Technological advancements have also played a significant role in the market's growth, with modern downdraft benches featuring more efficient filtration systems, ergonomic designs, and enhanced durability. As industries continue to prioritize worker safety and environmental sustainability, the demand for downdraft extraction benches is expected to rise, making it a vital component of industrial safety equipment.

Vertical Bench, Horizontal Bench in the Global Downdraft Extraction Bench Market:

Vertical and horizontal benches are two primary types of downdraft extraction benches available in the global market, each offering unique advantages tailored to specific applications. Vertical downdraft extraction benches are designed with a vertical airflow system that pulls contaminants downward through the work surface and into a filtration system located beneath the bench. This design is particularly effective for capturing heavier particles and dust, making it ideal for applications such as grinding, sanding, and welding. The vertical airflow ensures that contaminants are quickly removed from the worker's breathing zone, enhancing safety and comfort. On the other hand, horizontal downdraft extraction benches feature a horizontal airflow system that draws contaminants across the work surface and into side-mounted filters. This configuration is well-suited for tasks that generate lighter, more airborne particles, such as painting, spraying, and soldering. The horizontal airflow provides a more even distribution of suction across the work surface, ensuring efficient capture of fine particulates. Both types of benches are equipped with advanced filtration systems, including HEPA filters and activated carbon filters, to effectively remove a wide range of contaminants. Additionally, they often come with adjustable airflow settings, allowing users to customize the extraction rate based on the specific task at hand. Ergonomic features such as adjustable height and tilt options further enhance user comfort and productivity. In summary, while vertical downdraft extraction benches are ideal for heavy-duty applications involving larger particles, horizontal benches are better suited for tasks that produce finer, more airborne contaminants. The choice between the two depends on the specific requirements of the application, with both types offering significant benefits in terms of improving air quality and ensuring worker safety.

Manufacturing, Industrial, Pharmaceutical, Automotive, Military, Others in the Global Downdraft Extraction Bench Market:

The Global Downdraft Extraction Bench Market finds extensive usage across various sectors, including manufacturing, industrial, pharmaceutical, automotive, military, and others. In the manufacturing sector, these benches are crucial for processes such as welding, grinding, and cutting, where they effectively capture and filter out harmful fumes and dust, ensuring a safer working environment. In industrial settings, downdraft extraction benches are used for tasks like sanding, polishing, and deburring, where they help maintain air quality by removing particulate matter and other contaminants. The pharmaceutical industry relies on these benches to ensure a sterile and contaminant-free environment during the production of medicines and other healthcare products. They are particularly useful in processes that generate fine powders and chemical fumes, which need to be carefully controlled to prevent contamination and ensure product quality. In the automotive sector, downdraft extraction benches are used for tasks such as painting, spraying, and detailing, where they help capture overspray and fumes, ensuring a clean and safe workspace. The military sector also benefits from these benches, particularly in maintenance and repair operations where they help manage dust and fumes generated during tasks like sanding, welding, and painting. Other sectors that utilize downdraft extraction benches include electronics, woodworking, and metalworking, where they play a vital role in maintaining air quality and ensuring worker safety. Overall, the versatility and effectiveness of downdraft extraction benches make them an essential tool across a wide range of industries, helping to improve air quality, enhance worker safety, and ensure compliance with regulatory standards.

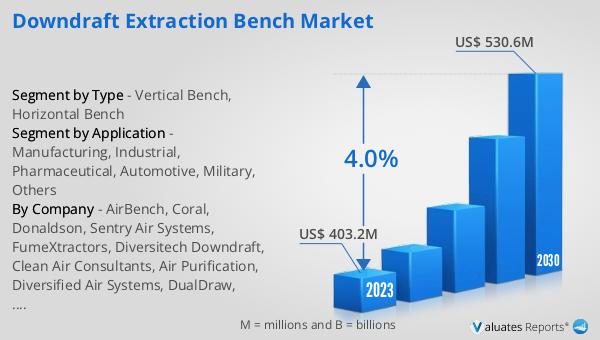

Global Downdraft Extraction Bench Market Outlook:

The global Downdraft Extraction Bench market was valued at US$ 403.2 million in 2023 and is anticipated to reach US$ 530.6 million by 2030, witnessing a CAGR of 4.0% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by increasing awareness of occupational health and safety standards, as well as stringent regulations aimed at reducing workplace hazards. The rising demand for cleaner and safer working environments across various industries, including manufacturing, industrial, pharmaceutical, automotive, and military, is a key factor contributing to this growth. Technological advancements in filtration systems, ergonomic designs, and enhanced durability of downdraft extraction benches are also playing a significant role in driving market expansion. As industries continue to prioritize worker safety and environmental sustainability, the demand for downdraft extraction benches is expected to rise, making it a vital component of industrial safety equipment. The market's growth is further supported by the increasing adoption of these benches in emerging economies, where industrialization and urbanization are driving the need for improved workplace safety measures. Overall, the global Downdraft Extraction Bench market is poised for significant growth in the coming years, driven by a combination of regulatory pressures, technological advancements, and increasing awareness of the importance of maintaining clean and safe working environments.

| Report Metric | Details |

| Report Name | Downdraft Extraction Bench Market |

| Accounted market size in 2023 | US$ 403.2 million |

| Forecasted market size in 2030 | US$ 530.6 million |

| CAGR | 4.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AirBench, Coral, Donaldson, Sentry Air Systems, FumeXtractors, Diversitech Downdraft, Clean Air Consultants, Air Purification, Diversified Air Systems, DualDraw, Controlled Air Design, DUST COLLECTOR SERVICES, Nederman, Efffe Group, Micro Air, Dynabrade, Air Daddy, Quality Air Management, AER Control Systems, CLEANTEK, MAXFLO, Aerservice Equipments, Filtrex, Plymex, Lincoln Electric, Avani Environmental, Diversitech, Plymovent, Sideros Engineering |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |