What is Global Portable Ultrasonic Phased Array Flaw Detector Market?

The Global Portable Ultrasonic Phased Array Flaw Detector Market refers to the industry focused on the development, production, and distribution of portable devices that use ultrasonic phased array technology to detect flaws in materials. These devices are essential in non-destructive testing (NDT) as they help identify internal defects such as cracks, voids, and inclusions in various materials without causing any damage. The technology works by emitting ultrasonic waves into the material and then analyzing the reflected waves to detect any anomalies. The portability of these devices makes them highly versatile and suitable for use in various industries, including construction, manufacturing, and aerospace. The market for these detectors is driven by the increasing demand for quality assurance and safety in industrial applications, as well as advancements in ultrasonic technology that enhance the accuracy and efficiency of flaw detection. The global market is characterized by a competitive landscape with numerous players offering a range of products tailored to different industrial needs.

Linear Probe, Dual Linear Probe, Matrix Probe in the Global Portable Ultrasonic Phased Array Flaw Detector Market:

In the Global Portable Ultrasonic Phased Array Flaw Detector Market, different types of probes are used to cater to various inspection requirements. The Linear Probe is one of the most commonly used types. It consists of multiple piezoelectric elements arranged in a straight line, which can be individually controlled to emit and receive ultrasonic waves. This configuration allows for the generation of a focused beam that can be swept across the material being inspected, providing detailed images of internal structures. Linear probes are particularly useful for inspecting flat or slightly curved surfaces and are widely used in industries such as aerospace and automotive for detecting surface and subsurface defects. The Dual Linear Probe, on the other hand, consists of two linear arrays positioned at an angle to each other. This design enables the probe to inspect complex geometries and provides better coverage of the material being tested. Dual linear probes are often used in applications where access to the inspection area is limited or where the material has intricate shapes. They are commonly employed in the inspection of welds, pipelines, and other critical components in the oil and gas industry. Matrix Probes represent a more advanced type of probe used in ultrasonic phased array flaw detection. These probes consist of a two-dimensional array of piezoelectric elements, allowing for the generation of ultrasonic beams in multiple directions. This capability enables the inspection of complex structures and provides a more comprehensive view of the material's internal condition. Matrix probes are highly versatile and can be used in a wide range of applications, including the inspection of composite materials, turbine blades, and other critical components in the aerospace and power generation industries. Each type of probe offers unique advantages and is selected based on the specific requirements of the inspection task. The choice of probe depends on factors such as the material being inspected, the type of defects being sought, and the accessibility of the inspection area. As technology continues to advance, the capabilities of these probes are expected to improve, further enhancing the effectiveness of ultrasonic phased array flaw detection in various industrial applications.

Architecture, Machine Manufacturing, Power Engineering, Chemical, Mining, Others in the Global Portable Ultrasonic Phased Array Flaw Detector Market:

The Global Portable Ultrasonic Phased Array Flaw Detector Market finds extensive usage across various industries, including architecture, machine manufacturing, power engineering, chemical, mining, and others. In architecture, these detectors are used to ensure the structural integrity of buildings and infrastructure. By detecting flaws in construction materials such as concrete and steel, these devices help prevent potential failures and enhance the safety and longevity of structures. This is particularly important in the construction of high-rise buildings, bridges, and other critical infrastructure where safety is paramount. In machine manufacturing, portable ultrasonic phased array flaw detectors are used to inspect components and assemblies for defects that could compromise their performance. This includes the inspection of metal parts, welds, and other critical components used in machinery and equipment. By identifying defects early in the manufacturing process, these detectors help ensure the quality and reliability of the final products, reducing the risk of costly failures and downtime. In the power engineering sector, these detectors play a crucial role in the maintenance and inspection of power generation equipment such as turbines, boilers, and pipelines. By detecting flaws in these critical components, the detectors help prevent catastrophic failures and ensure the continuous and efficient operation of power plants. This is particularly important in the context of nuclear power plants, where the safety and reliability of equipment are of utmost importance. The chemical industry also relies on portable ultrasonic phased array flaw detectors to inspect storage tanks, pipelines, and other critical infrastructure for defects. By detecting flaws such as corrosion, cracks, and weld defects, these detectors help prevent leaks and other failures that could result in hazardous spills and environmental contamination. This is essential for ensuring the safety of chemical plants and protecting the environment. In the mining industry, these detectors are used to inspect mining equipment and infrastructure for defects that could compromise their safety and performance. This includes the inspection of conveyor belts, crushers, and other critical components used in mining operations. By detecting flaws early, these detectors help prevent equipment failures and ensure the safety and efficiency of mining operations. Other industries that benefit from the use of portable ultrasonic phased array flaw detectors include aerospace, automotive, and oil and gas. In aerospace, these detectors are used to inspect aircraft components for defects that could compromise their safety and performance. In the automotive industry, they are used to inspect critical components such as engine parts and chassis for defects. In the oil and gas industry, they are used to inspect pipelines, storage tanks, and other critical infrastructure for defects that could result in leaks and other failures. Overall, the Global Portable Ultrasonic Phased Array Flaw Detector Market plays a vital role in ensuring the safety, reliability, and efficiency of various industrial applications. By providing accurate and reliable detection of flaws, these detectors help prevent failures, reduce downtime, and enhance the quality and performance of products and infrastructure.

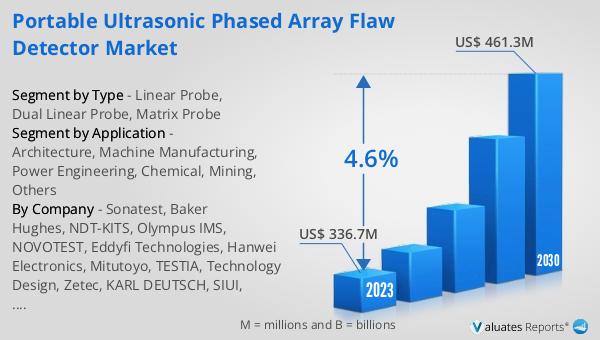

Global Portable Ultrasonic Phased Array Flaw Detector Market Outlook:

The global market for Portable Ultrasonic Phased Array Flaw Detectors was valued at $336.7 million in 2023 and is projected to grow to $461.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.6% over the forecast period from 2024 to 2030. This growth is driven by the increasing demand for non-destructive testing solutions across various industries, including construction, manufacturing, aerospace, and oil and gas. The advancements in ultrasonic technology, which enhance the accuracy and efficiency of flaw detection, are also contributing to the market's expansion. The market is characterized by a competitive landscape with numerous players offering a range of products tailored to different industrial needs. As industries continue to prioritize quality assurance and safety, the demand for portable ultrasonic phased array flaw detectors is expected to rise, further driving the market's growth. The market outlook indicates a positive trend, with significant opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Portable Ultrasonic Phased Array Flaw Detector Market |

| Accounted market size in 2023 | US$ 336.7 million |

| Forecasted market size in 2030 | US$ 461.3 million |

| CAGR | 4.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sonatest, Baker Hughes, NDT-KITS, Olympus IMS, NOVOTEST, Eddyfi Technologies, Hanwei Electronics, Mitutoyo, TESTIA, Technology Design, Zetec, KARL DEUTSCH, SIUI, Capital Instrument, Blue Star, TMTeck |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |