What is Global Wheel Brake Cylinder Market?

The Global Wheel Brake Cylinder Market refers to the worldwide industry involved in the production, distribution, and sale of wheel brake cylinders. These components are crucial in the braking systems of vehicles, converting hydraulic pressure into mechanical force to stop the wheels. The market encompasses a variety of vehicle types, including passenger cars, commercial vehicles, and heavy-duty trucks. It is influenced by factors such as technological advancements, regulatory standards, and the increasing demand for safety features in vehicles. The market is also driven by the growth in the automotive industry, particularly in emerging economies where vehicle ownership is rising. Additionally, the replacement and maintenance needs of existing vehicles contribute to the market's expansion. The global wheel brake cylinder market is characterized by a mix of established players and new entrants, all striving to innovate and improve the efficiency and reliability of their products.

Aluminum, Steel, Cast Iron in the Global Wheel Brake Cylinder Market:

In the Global Wheel Brake Cylinder Market, materials such as aluminum, steel, and cast iron play significant roles due to their unique properties and applications. Aluminum is favored for its lightweight nature, which contributes to overall vehicle efficiency and fuel economy. It is also resistant to corrosion, making it a durable choice for brake cylinders. However, aluminum can be more expensive compared to other materials, which might limit its use in cost-sensitive applications. Steel, on the other hand, is known for its strength and durability. It can withstand high pressures and temperatures, making it suitable for heavy-duty applications. Steel brake cylinders are often used in commercial vehicles and trucks where robustness is a priority. Despite its advantages, steel is prone to rust if not properly treated, which can affect its longevity. Cast iron is another material commonly used in the production of wheel brake cylinders. It is highly durable and can handle significant stress, making it ideal for heavy-duty and high-performance vehicles. Cast iron is also relatively cost-effective, which makes it a popular choice in the aftermarket segment. However, it is heavier than aluminum and steel, which can impact the overall weight of the vehicle and, consequently, its fuel efficiency. Each of these materials has its own set of advantages and disadvantages, and the choice often depends on the specific requirements of the vehicle and the market segment. For instance, high-performance sports cars might prefer aluminum for its lightweight properties, while commercial trucks might opt for steel or cast iron for their durability and strength. The ongoing advancements in material science are also leading to the development of new alloys and composites that aim to combine the best properties of these traditional materials. This continuous innovation is expected to further diversify the material landscape in the Global Wheel Brake Cylinder Market.

OEM, Aftermarket in the Global Wheel Brake Cylinder Market:

The Global Wheel Brake Cylinder Market finds its usage in two primary areas: Original Equipment Manufacturer (OEM) and Aftermarket. OEM refers to the production of brake cylinders that are installed in new vehicles during the manufacturing process. These components are designed to meet the specific requirements of the vehicle manufacturers and are often subject to stringent quality control measures. OEM brake cylinders are crucial for ensuring the safety and performance of new vehicles, and they are typically produced by well-established companies with a strong reputation in the automotive industry. The demand for OEM brake cylinders is closely tied to the overall health of the automotive industry, with higher vehicle production rates leading to increased demand for these components. On the other hand, the Aftermarket segment involves the production and sale of brake cylinders that are used as replacement parts for existing vehicles. This market is driven by the need for maintenance and repair of vehicles, which can arise from wear and tear, accidents, or other factors. Aftermarket brake cylinders are available in a wide range of quality and price points, catering to different customer needs and budgets. This segment is highly competitive, with numerous players offering products that range from high-end, performance-oriented brake cylinders to more affordable, standard options. The Aftermarket segment also benefits from the growing trend of vehicle longevity, as more consumers opt to keep their vehicles for longer periods, thereby increasing the need for replacement parts. Both the OEM and Aftermarket segments are essential for the overall growth and sustainability of the Global Wheel Brake Cylinder Market, each serving distinct but complementary roles in the automotive ecosystem.

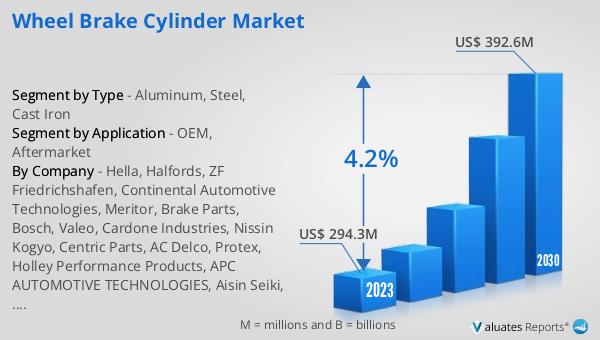

Global Wheel Brake Cylinder Market Outlook:

The global Wheel Brake Cylinder market was valued at US$ 294.3 million in 2023 and is anticipated to reach US$ 392.6 million by 2030, witnessing a CAGR of 4.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the wheel brake cylinder industry over the next several years. The valuation of US$ 294.3 million in 2023 reflects the current demand and production levels, driven by factors such as the increasing number of vehicles on the road, advancements in braking technology, and the need for regular maintenance and replacement of brake components. The projected growth to US$ 392.6 million by 2030 suggests that these factors will continue to drive the market forward. The compound annual growth rate (CAGR) of 4.2% indicates a moderate but consistent increase in market size, highlighting the ongoing importance of wheel brake cylinders in the automotive industry. This growth is likely to be supported by both the OEM and Aftermarket segments, as vehicle manufacturers continue to innovate and consumers maintain their vehicles for longer periods. Overall, the market outlook for the Global Wheel Brake Cylinder Market is positive, with steady growth expected over the forecast period.

| Report Metric | Details |

| Report Name | Wheel Brake Cylinder Market |

| Accounted market size in 2023 | US$ 294.3 million |

| Forecasted market size in 2030 | US$ 392.6 million |

| CAGR | 4.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hella, Halfords, ZF Friedrichshafen, Continental Automotive Technologies, Meritor, Brake Parts, Bosch, Valeo, Cardone Industries, Nissin Kogyo, Centric Parts, AC Delco, Protex, Holley Performance Products, APC AUTOMOTIVE TECHNOLOGIES, Aisin Seiki, Delphi, ADVICS, Dorman Products, AISIN Group, Raybestos |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |