What is Global Ultrasonic Inspection System Market?

The Global Ultrasonic Inspection System Market refers to the worldwide industry focused on the development, production, and application of ultrasonic inspection systems. These systems use high-frequency sound waves to detect flaws, measure thickness, and evaluate the properties of materials. They are widely used in various industries such as aerospace, oil and gas, nuclear energy, medical, and railway, among others. The market encompasses a range of products, including portable devices, automated systems, and specialized equipment designed for specific applications. The growth of this market is driven by the increasing demand for non-destructive testing methods that ensure the safety, reliability, and longevity of critical components and structures. Technological advancements, such as the integration of artificial intelligence and machine learning, are also contributing to the market's expansion by enhancing the accuracy and efficiency of ultrasonic inspection systems. As industries continue to prioritize quality control and regulatory compliance, the global ultrasonic inspection system market is expected to witness significant growth in the coming years.

Ultrasonic Immersion System, Squirter Ultrasonic Inspection, Pipe Testing Systems, Plate Inspection System, Others in the Global Ultrasonic Inspection System Market:

Ultrasonic Immersion Systems are a type of ultrasonic inspection system where the test object is submerged in a liquid, usually water, to facilitate the transmission of ultrasonic waves. This method is highly effective for inspecting complex geometries and detecting minute flaws. Squirter Ultrasonic Inspection, on the other hand, involves the use of a water jet to couple the ultrasonic transducer to the test object. This technique is particularly useful for inspecting large or irregularly shaped components. Pipe Testing Systems are specialized ultrasonic inspection systems designed to evaluate the integrity of pipes, which are critical in industries such as oil and gas, water supply, and chemical processing. These systems can detect corrosion, cracks, and other defects that could compromise the safety and functionality of the pipes. Plate Inspection Systems are used to inspect flat materials, such as metal plates, for defects like inclusions, voids, and delaminations. These systems are essential in industries where the quality of raw materials directly impacts the performance and safety of the final product. Other ultrasonic inspection systems include phased array ultrasonic testing, which uses multiple transducers to create a detailed image of the test object, and time-of-flight diffraction, which is used to detect and size cracks. Each of these systems has its unique advantages and applications, making them indispensable tools in the field of non-destructive testing.

Aerospace, Oil and Gas, Nuclear Energy, Medical, Railway, Others in the Global Ultrasonic Inspection System Market:

The Global Ultrasonic Inspection System Market finds extensive usage across various industries due to its ability to provide accurate, reliable, and non-destructive testing solutions. In the aerospace industry, ultrasonic inspection systems are used to ensure the structural integrity of aircraft components, such as wings, fuselage, and engines. These systems help detect flaws that could lead to catastrophic failures, thereby enhancing the safety and reliability of aircraft. In the oil and gas industry, ultrasonic inspection systems are employed to inspect pipelines, storage tanks, and other critical infrastructure. They help identify corrosion, cracks, and other defects that could result in leaks or explosions, ensuring the safe and efficient operation of oil and gas facilities. The nuclear energy sector also relies heavily on ultrasonic inspection systems to monitor the condition of reactor components, pressure vessels, and piping systems. These systems help detect early signs of wear and tear, preventing potential accidents and ensuring the safe operation of nuclear power plants. In the medical field, ultrasonic inspection systems are used to inspect medical devices, such as implants and surgical instruments, for defects that could compromise patient safety. They are also used in the development and quality control of new medical technologies. The railway industry uses ultrasonic inspection systems to inspect rails, wheels, and other components for defects that could lead to derailments or other accidents. Other industries, such as automotive, manufacturing, and construction, also utilize ultrasonic inspection systems to ensure the quality and safety of their products and infrastructure. The versatility and effectiveness of ultrasonic inspection systems make them a critical tool in maintaining the safety, reliability, and performance of various industrial applications.

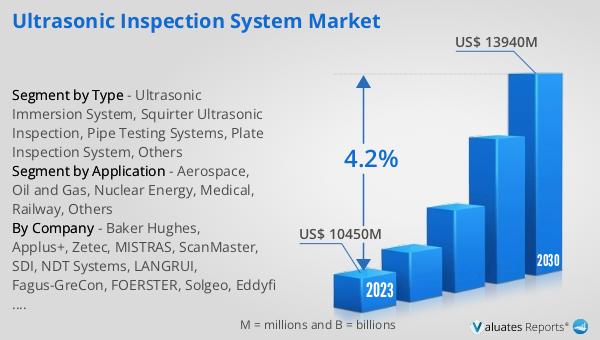

Global Ultrasonic Inspection System Market Outlook:

The global Ultrasonic Inspection System market, valued at US$ 10,450 million in 2023, is projected to reach US$ 13,940 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.2% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for non-destructive testing methods across various industries, including aerospace, oil and gas, nuclear energy, medical, and railway. The market's expansion is further supported by technological advancements, such as the integration of artificial intelligence and machine learning, which enhance the accuracy and efficiency of ultrasonic inspection systems. As industries continue to prioritize quality control and regulatory compliance, the adoption of ultrasonic inspection systems is expected to rise, contributing to the market's growth. The versatility and effectiveness of these systems in detecting flaws, measuring thickness, and evaluating material properties make them indispensable tools in ensuring the safety, reliability, and longevity of critical components and structures. With the ongoing emphasis on safety and quality in industrial applications, the global ultrasonic inspection system market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Ultrasonic Inspection System Market |

| Accounted market size in 2023 | US$ 10450 million |

| Forecasted market size in 2030 | US$ 13940 million |

| CAGR | 4.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Baker Hughes, Applus+, Zetec, MISTRAS, ScanMaster, SDI, NDT Systems, LANGRUI, Fagus-GreCon, FOERSTER, Solgeo, Eddyfi Technologies, KARL DEUTSCH, Sonatest, Sonotron, Gilardoni, Miller Weldmaster, Hangzhou Zheda Jingyi Electromechanical Technology, VOGT Ultrasonics, Nordco Inspection Technologies, Olympus, Eclipse Scientific |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |