What is Molybdenum Electrodes for Glass Furnace - Global Market?

Molybdenum electrodes are crucial components in glass furnaces, playing a significant role in the global market. These electrodes are primarily used in the glass manufacturing industry due to their high melting point, excellent conductivity, and resistance to corrosion. Molybdenum, a refractory metal, is ideal for withstanding the extreme temperatures and harsh conditions within glass furnaces. The global market for molybdenum electrodes is driven by the increasing demand for high-quality glass products across various industries, including construction, automotive, and consumer electronics. As the glass industry continues to grow, the need for efficient and durable furnace components like molybdenum electrodes becomes more pronounced. Manufacturers are constantly innovating to improve the performance and longevity of these electrodes, ensuring they meet the evolving needs of the glass production process. The market is characterized by a mix of established players and new entrants, all striving to capture a share of this expanding market. With advancements in technology and increasing environmental regulations, the demand for molybdenum electrodes is expected to rise, making it a vital component in the glass manufacturing sector.

Purity above 99.9%, Purity above 99.99% in the Molybdenum Electrodes for Glass Furnace - Global Market:

When discussing the purity levels of molybdenum electrodes for glass furnaces, two primary categories are often highlighted: those with a purity above 99.9% and those with a purity above 99.99%. The purity of molybdenum is a critical factor that influences the performance and efficiency of the electrodes in glass production. Electrodes with a purity above 99.9% are widely used due to their ability to provide a stable and consistent performance in high-temperature environments. These electrodes are suitable for most standard glass manufacturing processes, offering a balance between cost and performance. On the other hand, electrodes with a purity above 99.99% are considered premium products, designed for applications that require the highest level of precision and quality. These high-purity electrodes are often used in the production of specialty glass products, where even the slightest impurities can affect the final product's quality. The manufacturing process for these high-purity electrodes involves advanced refining techniques to ensure that impurities are minimized to the greatest extent possible. This level of purity ensures that the electrodes have a longer lifespan and can withstand the rigorous demands of continuous glass production. The choice between these two purity levels depends largely on the specific requirements of the glass manufacturing process and the desired quality of the final product. As the glass industry continues to evolve, the demand for high-purity molybdenum electrodes is expected to increase, driven by the need for more efficient and sustainable production methods. Manufacturers are investing in research and development to enhance the purity and performance of molybdenum electrodes, ensuring they meet the stringent demands of modern glass production. The global market for these electrodes is competitive, with numerous players offering a range of products to cater to the diverse needs of the glass industry. As environmental concerns and regulatory pressures mount, the emphasis on high-purity electrodes is likely to grow, making them an essential component in the quest for cleaner and more efficient glass manufacturing processes.

Daily Use Glass, Optical Glass, Industrial Glass in the Molybdenum Electrodes for Glass Furnace - Global Market:

Molybdenum electrodes are extensively used in various types of glass production, including daily use glass, optical glass, and industrial glass. In the realm of daily use glass, which encompasses products like bottles, jars, and tableware, molybdenum electrodes are valued for their ability to maintain consistent heat and ensure uniform melting of raw materials. This consistency is crucial for producing glass products that are both aesthetically pleasing and functionally reliable. The durability and efficiency of molybdenum electrodes help manufacturers maintain high production rates while minimizing defects, which is essential in a highly competitive market where cost-effectiveness is key. In the production of optical glass, which is used in lenses, prisms, and other precision instruments, the role of molybdenum electrodes becomes even more critical. Optical glass requires a high degree of clarity and precision, and any impurities or inconsistencies in the melting process can lead to significant defects. Molybdenum electrodes, particularly those with higher purity levels, provide the stability and precision needed to produce optical glass of the highest quality. Their ability to withstand high temperatures without degrading ensures that the glass maintains its optical properties throughout the production process. In the industrial glass sector, which includes products like glass fibers, laboratory glassware, and glass used in construction, molybdenum electrodes are essential for their robustness and longevity. Industrial glass production often involves continuous processes that require components capable of enduring prolonged exposure to extreme conditions. Molybdenum electrodes meet these demands, offering a reliable solution that minimizes downtime and maintenance costs. Their resistance to corrosion and thermal shock makes them ideal for industrial applications where reliability and performance are paramount. Across all these areas, the use of molybdenum electrodes contributes to the efficiency and quality of glass production, making them indispensable in the global glass furnace market. As industries continue to demand higher quality and more sustainable glass products, the role of molybdenum electrodes is likely to expand, driving further innovation and development in this critical area.

Molybdenum Electrodes for Glass Furnace - Global Market Outlook:

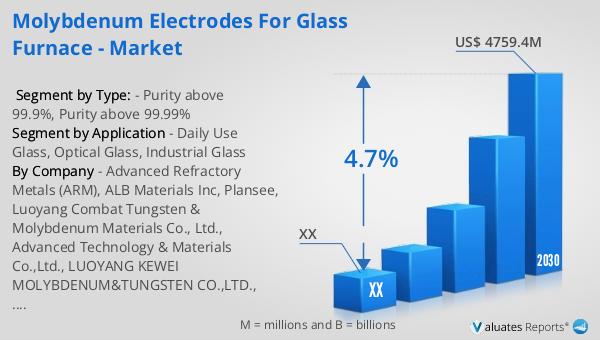

The global market for molybdenum electrodes used in glass furnaces was valued at approximately $3,355 million in 2023. This market is projected to grow, reaching an estimated value of $4,759.4 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.7% during the forecast period from 2024 to 2030. This upward trend is indicative of the increasing demand for high-quality glass products across various industries, which in turn drives the need for efficient and durable furnace components like molybdenum electrodes. The market's expansion is fueled by advancements in glass manufacturing technologies and the growing emphasis on sustainability and energy efficiency. As manufacturers strive to meet these demands, the adoption of molybdenum electrodes is expected to rise, contributing to the market's growth. The competitive landscape of the market is characterized by a mix of established players and new entrants, all vying for a share of this lucrative market. With ongoing research and development efforts aimed at enhancing the performance and longevity of molybdenum electrodes, the market is poised for continued growth and innovation. As environmental regulations become more stringent, the demand for high-purity and efficient molybdenum electrodes is likely to increase, further driving the market's expansion.

| Report Metric | Details |

| Report Name | Molybdenum Electrodes for Glass Furnace - Market |

| Forecasted market size in 2030 | US$ 4759.4 million |

| CAGR | 4.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Advanced Refractory Metals (ARM), ALB Materials Inc, Plansee, Luoyang Combat Tungsten & Molybdenum Materials Co., Ltd., Advanced Technology & Materials Co.,Ltd., LUOYANG KEWEI MOLYBDENUM&TUNGSTEN CO.,LTD., Nantong Guangming Molybdenum Products Factory, LUOYANG FORGED TUNGSTEN&MOLYBDENUM MATERIAL CO.,LTD., JINDUICHENG MOLYBDENUM CO.,LTD., Xiamen Tungsten Co.,Ltd., LUO YANG XINGTU MOLYBDENUM&TUNGSTEN TECHNOLOGY CO.,LTD, BGRIMM Advanced Materials Science&Technology Co.,Ltd, LUOYANG METALLINE TUNGSTEN AND MOLYBDENUM MATERIAL, LUOYANG RARE METAL RESEARCH MATERIAL CO.,LTD., Henan World Expo Tungsten and Molybdenum Technology, Shaanxi Juhe Nonferrous Metals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |