What is Global Handheld Magnetic Gauss Meter Market?

The Global Handheld Magnetic Gauss Meter Market refers to the worldwide industry focused on the production, distribution, and utilization of handheld devices designed to measure magnetic fields. These meters, also known as gauss meters, are essential tools in various fields for detecting and quantifying magnetic flux density. The market encompasses a range of products from basic analog models to advanced digital versions, catering to diverse applications across different sectors. The demand for these devices is driven by their critical role in ensuring the proper functioning of equipment, maintaining safety standards, and conducting research and development activities. As industries continue to advance technologically, the need for precise and reliable magnetic field measurements becomes increasingly important, thereby fueling the growth of the global handheld magnetic gauss meter market.

Analog Gauss Meter, Digital Gauss Meter in the Global Handheld Magnetic Gauss Meter Market:

Analog Gauss Meters and Digital Gauss Meters are two primary types of devices within the Global Handheld Magnetic Gauss Meter Market, each serving distinct purposes based on their design and functionality. Analog Gauss Meters are traditional devices that use a needle and dial to display magnetic field strength. These meters are valued for their simplicity, durability, and ease of use, making them suitable for applications where quick, straightforward readings are sufficient. They are often preferred in educational settings, basic industrial applications, and situations where digital technology might be unnecessary or too costly. On the other hand, Digital Gauss Meters represent the modern evolution of magnetic field measurement tools. These devices offer enhanced precision, advanced features, and greater versatility compared to their analog counterparts. Digital Gauss Meters typically come equipped with LCD screens, data logging capabilities, and connectivity options such as USB or Bluetooth, allowing for more detailed analysis and integration with other digital systems. They are particularly useful in high-tech industries, research laboratories, and any application requiring meticulous measurement and data recording. The choice between analog and digital gauss meters depends largely on the specific needs of the user, the complexity of the measurement tasks, and the environment in which the device will be used. Both types of meters play crucial roles in the global market, catering to a wide range of applications and industries.

Industrial, Automotive, Aerospace, Electronic, Others in the Global Handheld Magnetic Gauss Meter Market:

The usage of handheld magnetic gauss meters spans across various sectors, including industrial, automotive, aerospace, electronic, and others, each benefiting from the precise measurement capabilities these devices offer. In the industrial sector, gauss meters are essential for monitoring and maintaining the performance of machinery and equipment that rely on magnetic fields. They help in detecting magnetic interference, ensuring the proper functioning of motors, generators, and other magnetic devices, and maintaining safety standards. In the automotive industry, these meters are used to test and validate the performance of components such as sensors, actuators, and electric motors, which are critical in modern vehicles, especially electric and hybrid models. The aerospace sector relies on gauss meters for the development and maintenance of navigation systems, communication devices, and other critical components that depend on accurate magnetic field measurements. In the electronics industry, gauss meters are used to test and calibrate magnetic sensors, hard drives, and other devices that operate based on magnetic principles. Additionally, other sectors such as healthcare, research, and education also utilize these meters for various applications, including medical imaging, scientific experiments, and teaching purposes. The versatility and precision of handheld magnetic gauss meters make them indispensable tools across these diverse fields, contributing to their widespread adoption and continuous demand.

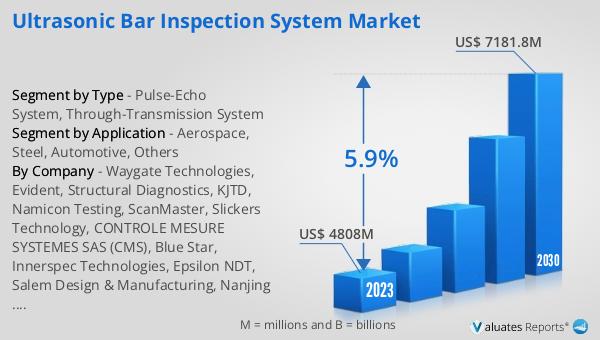

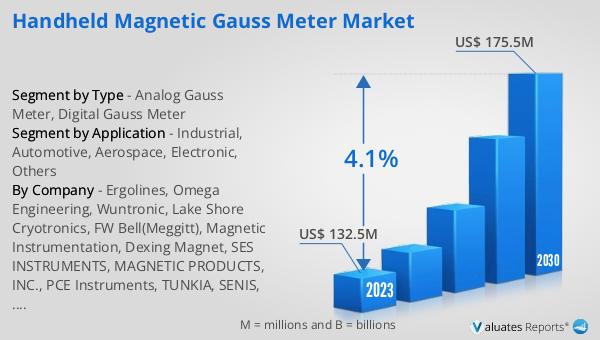

Global Handheld Magnetic Gauss Meter Market Outlook:

The global Handheld Magnetic Gauss Meter market was valued at US$ 132.5 million in 2023 and is anticipated to reach US$ 175.5 million by 2030, witnessing a CAGR of 4.1% during the forecast period from 2024 to 2030. This market outlook highlights the steady growth and increasing demand for handheld magnetic gauss meters across various industries. The projected growth can be attributed to the rising need for accurate magnetic field measurements in sectors such as industrial, automotive, aerospace, and electronics. As technological advancements continue to drive innovation in these fields, the demand for reliable and precise measurement tools like gauss meters is expected to grow. The market's expansion is also supported by the increasing adoption of digital gauss meters, which offer enhanced features and capabilities compared to traditional analog models. Overall, the global handheld magnetic gauss meter market is poised for significant growth in the coming years, driven by the ongoing advancements in technology and the growing need for accurate magnetic field measurements across various applications.

| Report Metric | Details |

| Report Name | Handheld Magnetic Gauss Meter Market |

| Accounted market size in 2023 | US$ 132.5 million |

| Forecasted market size in 2030 | US$ 175.5 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ergolines, Omega Engineering, Wuntronic, Lake Shore Cryotronics, FW Bell(Meggitt), Magnetic Instrumentation, Dexing Magnet, SES INSTRUMENTS, MAGNETIC PRODUCTS, INC., PCE Instruments, TUNKIA, SENIS, AlphaLab, Master Magnetics, Brockhaus, Goudsmit Magnetic, Magnosphere, KANETEC, Extech Instrument, Fluke, TPI, Lutron Electronics, Trifield |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |