What is Global Ultrasonic Bar Inspection System Market?

The Global Ultrasonic Bar Inspection System Market is a specialized segment within the broader non-destructive testing (NDT) industry. This market focuses on the use of ultrasonic technology to inspect bars and rods for internal defects, ensuring their structural integrity and quality. Ultrasonic bar inspection systems utilize high-frequency sound waves to detect flaws such as cracks, voids, and inclusions within the material. These systems are essential in industries where material integrity is critical, such as aerospace, automotive, and steel manufacturing. The technology offers a reliable and efficient method for quality control, reducing the risk of material failure and enhancing product safety. The market has seen significant growth due to increasing demand for high-quality materials and stringent regulatory standards. Innovations in ultrasonic technology, such as advanced signal processing and automation, have further propelled the market, making inspections faster and more accurate. As industries continue to prioritize safety and quality, the Global Ultrasonic Bar Inspection System Market is expected to expand, driven by technological advancements and the need for rigorous quality assurance processes.

Pulse-Echo System, Through-Transmission System in the Global Ultrasonic Bar Inspection System Market:

The Pulse-Echo System and Through-Transmission System are two primary methods used in the Global Ultrasonic Bar Inspection System Market. The Pulse-Echo System operates by emitting a short ultrasonic pulse into the material and then receiving the echoes that bounce back from internal features or defects. This method is highly effective for detecting surface and near-surface flaws, as well as for measuring thickness. The time it takes for the echo to return is used to calculate the distance to the defect, providing precise information about its location and size. This system is widely used due to its simplicity and effectiveness in identifying a wide range of defects. On the other hand, the Through-Transmission System involves two transducers placed on opposite sides of the material being inspected. One transducer acts as a transmitter, sending ultrasonic waves through the material, while the other acts as a receiver, capturing the waves that pass through. This method is particularly useful for detecting internal defects that may not be easily identified by the Pulse-Echo System. By measuring the attenuation or loss of signal strength as the waves pass through the material, the Through-Transmission System can identify areas of weakness or discontinuity within the bar. This method is highly effective for inspecting thicker materials and for applications where detecting internal flaws is critical. Both systems have their unique advantages and are often used in combination to provide a comprehensive inspection. The Pulse-Echo System is advantageous for its ability to provide detailed information about the location and size of defects, making it ideal for applications where precise defect characterization is required. The Through-Transmission System, with its ability to detect internal flaws, is essential for ensuring the overall integrity of the material. Together, these systems offer a robust solution for ultrasonic bar inspection, ensuring that materials meet stringent quality standards and are free from critical defects. In the Global Ultrasonic Bar Inspection System Market, advancements in technology have further enhanced the capabilities of both the Pulse-Echo and Through-Transmission Systems. Innovations such as phased array technology, which uses multiple transducers to create a detailed image of the material's internal structure, have significantly improved the accuracy and efficiency of inspections. Additionally, the integration of automated systems and advanced signal processing techniques has made it possible to conduct inspections more quickly and with greater precision, reducing the likelihood of human error and increasing the reliability of the results. Overall, the Pulse-Echo and Through-Transmission Systems play a crucial role in the Global Ultrasonic Bar Inspection System Market, providing essential tools for ensuring the quality and integrity of materials used in critical applications. As industries continue to demand higher standards of quality and safety, the importance of these systems is only expected to grow, driving further innovation and development in the field of ultrasonic inspection.

Aerospace, Steel, Automotive, Others in the Global Ultrasonic Bar Inspection System Market:

The Global Ultrasonic Bar Inspection System Market finds extensive usage across various industries, including aerospace, steel, automotive, and others. In the aerospace industry, the integrity of materials is paramount, as even minor defects can lead to catastrophic failures. Ultrasonic bar inspection systems are used to ensure that the bars and rods used in aircraft components are free from internal defects, such as cracks or voids, that could compromise their structural integrity. The high precision and reliability of ultrasonic inspection make it an indispensable tool for maintaining the safety and performance of aerospace components. In the steel industry, ultrasonic bar inspection systems are used to inspect steel bars and rods for internal defects that could affect their strength and durability. Steel is a critical material in construction, manufacturing, and various other applications, and ensuring its quality is essential for the safety and reliability of the structures and products it is used in. Ultrasonic inspection provides a non-destructive method for detecting internal flaws, allowing manufacturers to identify and address defects before the material is used in critical applications. This helps to prevent material failures and ensures that the steel meets the required quality standards. The automotive industry also relies heavily on ultrasonic bar inspection systems to ensure the quality and safety of the materials used in vehicle components. Automotive manufacturers use these systems to inspect bars and rods for internal defects that could affect the performance and safety of the vehicle. For example, ultrasonic inspection is used to check the integrity of engine components, suspension parts, and other critical elements that must withstand high stresses and loads. By ensuring that these components are free from defects, ultrasonic inspection helps to enhance the safety and reliability of vehicles. Beyond aerospace, steel, and automotive, ultrasonic bar inspection systems are used in various other industries where material integrity is critical. For example, in the energy sector, these systems are used to inspect bars and rods used in pipelines, power plants, and other infrastructure to ensure their reliability and safety. In the medical field, ultrasonic inspection is used to check the quality of materials used in medical devices and implants, ensuring that they meet stringent safety and performance standards. The versatility and reliability of ultrasonic inspection make it a valuable tool in any industry where material quality is of utmost importance. Overall, the Global Ultrasonic Bar Inspection System Market plays a crucial role in ensuring the quality and safety of materials used in a wide range of industries. By providing a reliable and non-destructive method for detecting internal defects, these systems help to prevent material failures and ensure that products meet the required quality standards. As industries continue to prioritize safety and quality, the demand for ultrasonic bar inspection systems is expected to grow, driving further advancements in the technology and expanding its applications across various sectors.

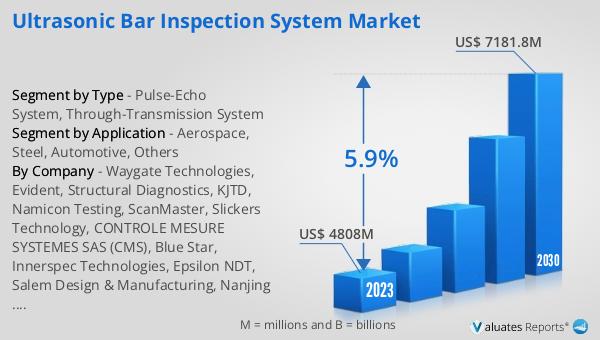

Global Ultrasonic Bar Inspection System Market Outlook:

The global Ultrasonic Bar Inspection System market was valued at US$ 4808 million in 2023 and is anticipated to reach US$ 7181.8 million by 2030, witnessing a CAGR of 5.9% during the forecast period 2024-2030. This market growth reflects the increasing demand for high-quality materials and the need for stringent quality control measures across various industries. Ultrasonic bar inspection systems provide a reliable and efficient method for detecting internal defects in bars and rods, ensuring their structural integrity and quality. The market has seen significant advancements in technology, such as the development of advanced signal processing techniques and automation, which have enhanced the accuracy and efficiency of inspections. These innovations have made it possible to conduct inspections more quickly and with greater precision, reducing the likelihood of human error and increasing the reliability of the results. As industries continue to prioritize safety and quality, the Global Ultrasonic Bar Inspection System Market is expected to expand, driven by technological advancements and the need for rigorous quality assurance processes.

| Report Metric | Details |

| Report Name | Ultrasonic Bar Inspection System Market |

| Accounted market size in 2023 | US$ 4808 million |

| Forecasted market size in 2030 | US$ 7181.8 million |

| CAGR | 5.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Waygate Technologies, Evident, Structural Diagnostics, KJTD, Namicon Testing, ScanMaster, Slickers Technology, CONTROLE MESURE SYSTEMES SAS (CMS), Blue Star, Innerspec Technologies, Epsilon NDT, Salem Design & Manufacturing, Nanjing BKN, Nordco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |