What is New Energy Vehicle Power Battery Adhesives - Global Market?

New Energy Vehicle Power Battery Adhesives are specialized materials used in the assembly and manufacturing of batteries for new energy vehicles, such as electric cars and hybrid vehicles. These adhesives play a crucial role in ensuring the structural integrity, safety, and performance of the battery packs. As the demand for electric vehicles (EVs) continues to rise globally, the market for these adhesives is also expanding. The adhesives are designed to withstand extreme temperatures, vibrations, and other environmental factors that batteries may encounter during their lifecycle. They help in bonding various components of the battery, such as cells, modules, and packs, ensuring that they remain securely in place. Additionally, these adhesives contribute to the overall efficiency and longevity of the battery by providing thermal management and electrical insulation. The global market for New Energy Vehicle Power Battery Adhesives is driven by the increasing adoption of EVs, advancements in battery technology, and the need for sustainable and efficient energy solutions. As countries worldwide push for greener transportation options, the demand for these adhesives is expected to grow, making them a vital component in the EV manufacturing process.

Polyurethane Adhesive, Epoxy Adhesive, Silicone Adhesive, Other in the New Energy Vehicle Power Battery Adhesives - Global Market:

Polyurethane Adhesive, Epoxy Adhesive, Silicone Adhesive, and other types of adhesives each play a unique role in the New Energy Vehicle Power Battery Adhesives market. Polyurethane Adhesives are known for their flexibility and durability, making them ideal for applications that require strong bonding and resistance to environmental factors. They are often used in battery modules and packs to provide structural support and vibration resistance. Polyurethane adhesives can also offer excellent thermal stability, which is crucial for maintaining battery performance under varying temperature conditions. Epoxy Adhesives, on the other hand, are renowned for their high strength and excellent chemical resistance. They are commonly used in applications where a strong, permanent bond is required. Epoxy adhesives are particularly useful in bonding metal and composite materials within the battery, ensuring that the components remain securely attached even under stress. Their ability to withstand harsh chemicals and extreme temperatures makes them a preferred choice for many manufacturers. Silicone Adhesives are valued for their flexibility and ability to withstand extreme temperatures. They are often used in applications where thermal management is critical, as they can effectively dissipate heat generated by the battery. Silicone adhesives also provide excellent electrical insulation, which is essential for preventing short circuits and ensuring the safety of the battery. Other types of adhesives, such as acrylic and cyanoacrylate, also find applications in the New Energy Vehicle Power Battery Adhesives market. These adhesives offer unique properties that can be tailored to specific requirements, such as fast curing times or specific bonding strengths. The choice of adhesive depends on various factors, including the materials being bonded, the operating environment, and the specific performance requirements of the battery. As the market for new energy vehicles continues to grow, manufacturers are constantly seeking innovative adhesive solutions that can enhance the performance, safety, and longevity of their battery systems. This has led to ongoing research and development efforts aimed at improving the properties of existing adhesives and developing new formulations that can meet the evolving needs of the industry.

BEV, HEV in the New Energy Vehicle Power Battery Adhesives - Global Market:

The usage of New Energy Vehicle Power Battery Adhesives is particularly significant in Battery Electric Vehicles (BEVs) and Hybrid Electric Vehicles (HEVs). In BEVs, which rely entirely on electric power, the battery is the most critical component. The adhesives used in these vehicles must ensure that the battery cells and modules are securely bonded to withstand the stresses of daily use, including vibrations, temperature fluctuations, and potential impacts. The adhesives also play a vital role in thermal management, helping to dissipate heat generated during charging and discharging cycles. This is crucial for maintaining the efficiency and safety of the battery, as excessive heat can lead to reduced performance or even safety hazards. In HEVs, which combine an internal combustion engine with an electric propulsion system, the role of battery adhesives is equally important. The adhesives must provide strong bonding and insulation to ensure that the battery components remain intact and functional. Given that HEVs operate in a wide range of conditions, from city driving to highway speeds, the adhesives must be able to withstand varying environmental factors. Additionally, the adhesives contribute to the overall weight reduction of the vehicle by allowing for the use of lighter materials in the battery construction. This is important for improving the fuel efficiency and performance of HEVs. As the automotive industry continues to innovate and develop new energy vehicles, the demand for advanced adhesive solutions is expected to grow. Manufacturers are increasingly focusing on developing adhesives that offer improved performance, safety, and sustainability. This includes exploring new materials and formulations that can provide better bonding, thermal management, and electrical insulation. The ongoing advancements in adhesive technology are playing a crucial role in enabling the widespread adoption of BEVs and HEVs, contributing to a more sustainable and environmentally friendly transportation future.

New Energy Vehicle Power Battery Adhesives - Global Market Outlook:

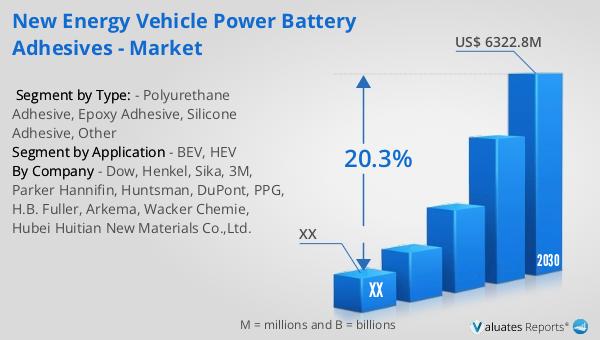

The global market for New Energy Vehicle Power Battery Adhesives was valued at approximately US$ 1,878 million in 2023. It is projected to grow significantly, reaching an estimated size of US$ 6,322.8 million by 2030. This growth represents a compound annual growth rate (CAGR) of 20.3% during the forecast period from 2024 to 2030. The North American market for these adhesives also shows promising potential, although specific figures for 2023 and 2030 are not provided. The rapid expansion of this market can be attributed to the increasing demand for electric vehicles and the continuous advancements in battery technology. As more countries and regions implement policies to promote sustainable transportation, the need for efficient and reliable battery adhesives becomes more critical. These adhesives are essential for ensuring the safety, performance, and longevity of new energy vehicle batteries. The market's growth is further supported by ongoing research and development efforts aimed at improving adhesive formulations and discovering new materials that can meet the evolving needs of the automotive industry. As a result, the New Energy Vehicle Power Battery Adhesives market is poised for substantial growth in the coming years, driven by the global shift towards cleaner and more sustainable transportation solutions.

| Report Metric | Details |

| Report Name | New Energy Vehicle Power Battery Adhesives - Market |

| Forecasted market size in 2030 | US$ 6322.8 million |

| CAGR | 20.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dow, Henkel, Sika, 3M, Parker Hannifin, Huntsman, DuPont, PPG, H.B. Fuller, Arkema, Wacker Chemie, Hubei Huitian New Materials Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |