What is Thermal Conductive Adhesives for Electric Vehicles - Global Market?

Thermal conductive adhesives are specialized materials used in electric vehicles (EVs) to manage heat effectively. These adhesives are crucial in ensuring that the components within an EV operate efficiently and safely by dissipating heat generated during operation. As the demand for electric vehicles continues to rise globally, the market for thermal conductive adhesives is also expanding. These adhesives are used to bond components while simultaneously conducting heat away from sensitive parts, preventing overheating and potential damage. They are essential in maintaining the performance and longevity of EV components such as batteries, electronic control units, and other electronic systems. The global market for these adhesives is growing rapidly, driven by the increasing adoption of electric vehicles and advancements in adhesive technology that enhance thermal management capabilities. This growth is further fueled by the push for more sustainable and energy-efficient transportation solutions, making thermal conductive adhesives a vital component in the EV industry.

Silicone Adhesive, Polyurethane Adhesive, Others in the Thermal Conductive Adhesives for Electric Vehicles - Global Market:

Silicone adhesives are a popular choice in the thermal conductive adhesives market for electric vehicles due to their excellent thermal stability and flexibility. These adhesives can withstand high temperatures and maintain their properties over a wide range of conditions, making them ideal for use in EV applications where thermal management is critical. Silicone adhesives provide strong bonding capabilities and are resistant to environmental factors such as moisture and UV radiation, which enhances the durability and reliability of the bonded components. They are often used in applications where flexibility and thermal conductivity are required, such as in battery packs and electronic control systems. Polyurethane adhesives, on the other hand, offer a different set of advantages. They are known for their strong adhesive properties and ability to bond a variety of materials, including metals and plastics. Polyurethane adhesives are also valued for their toughness and resistance to impact, making them suitable for applications where mechanical stress is a concern. These adhesives provide good thermal conductivity and are often used in applications where a strong bond and thermal management are needed, such as in power electronics and battery modules. Other types of thermal conductive adhesives include epoxy-based adhesives, which are known for their excellent thermal conductivity and strong bonding capabilities. Epoxy adhesives are often used in applications where high thermal conductivity is required, such as in heat sinks and thermal interface materials. They provide a strong bond and are resistant to environmental factors, making them suitable for use in harsh conditions. Each type of adhesive offers unique properties that make them suitable for specific applications within the electric vehicle market, and the choice of adhesive depends on the specific requirements of the application, such as thermal conductivity, flexibility, and environmental resistance.

Power Battery Pack Application, Electronic Control System Application in the Thermal Conductive Adhesives for Electric Vehicles - Global Market:

Thermal conductive adhesives play a crucial role in the power battery pack applications of electric vehicles. These adhesives are used to bond battery cells together and to attach them to the battery pack housing, ensuring a secure and stable connection. The thermal conductivity of these adhesives helps to dissipate heat generated during battery operation, preventing overheating and ensuring the efficient performance of the battery pack. This is particularly important in electric vehicles, where battery performance directly impacts the vehicle's range and efficiency. By effectively managing heat, thermal conductive adhesives help to extend the lifespan of the battery pack and improve the overall performance of the electric vehicle. In electronic control system applications, thermal conductive adhesives are used to bond and secure electronic components, such as control units and sensors, to the vehicle's chassis or other components. These adhesives provide a strong bond and help to dissipate heat generated by the electronic components, preventing overheating and ensuring reliable operation. The use of thermal conductive adhesives in electronic control systems is essential for maintaining the performance and reliability of the vehicle's electronic systems, which are critical for the safe and efficient operation of the vehicle. By managing heat effectively, these adhesives help to prevent damage to electronic components and ensure the long-term reliability of the vehicle's electronic systems.

Thermal Conductive Adhesives for Electric Vehicles - Global Market Outlook:

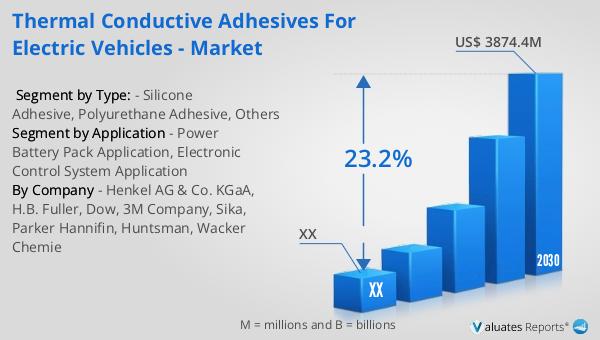

The global market for thermal conductive adhesives used in electric vehicles was valued at approximately $925 million in 2023. This market is projected to grow significantly, reaching an estimated size of $3,874.4 million by 2030, with a compound annual growth rate (CAGR) of 23.2% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for electric vehicles worldwide, as consumers and manufacturers alike seek more sustainable and energy-efficient transportation solutions. In 2022, sales of pure electric vehicles in Europe alone increased by 29% year-on-year, reaching 1.58 million units. This surge in EV sales highlights the growing acceptance and adoption of electric vehicles, which in turn drives the demand for thermal conductive adhesives. As electric vehicles become more prevalent, the need for effective thermal management solutions becomes increasingly important, further fueling the growth of the thermal conductive adhesives market. The market's expansion is also supported by advancements in adhesive technology, which enhance the thermal management capabilities of these adhesives, making them more effective and reliable in EV applications.

| Report Metric | Details |

| Report Name | Thermal Conductive Adhesives for Electric Vehicles - Market |

| Forecasted market size in 2030 | US$ 3874.4 million |

| CAGR | 23.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel AG & Co. KGaA, H.B. Fuller, Dow, 3M Company, Sika, Parker Hannifin, Huntsman, Wacker Chemie |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |