What is Global Ultrasonic Precision Thickness Gauge Market?

The Global Ultrasonic Precision Thickness Gauge Market refers to the worldwide industry focused on the production, distribution, and application of ultrasonic precision thickness gauges. These devices are essential tools used to measure the thickness of various materials with high accuracy. They operate by emitting ultrasonic waves that penetrate the material and reflect back, allowing the device to calculate the thickness based on the time it takes for the waves to return. This market encompasses a wide range of industries, including automotive, aerospace, manufacturing, and construction, where precise material measurements are crucial for quality control and safety. The market is driven by the increasing demand for non-destructive testing methods, advancements in ultrasonic technology, and the need for accurate measurements in complex materials. As industries continue to prioritize quality and safety, the demand for ultrasonic precision thickness gauges is expected to grow, making this market a vital component of modern industrial practices.

Analog Thickness Gauge, Digital Thickness Gauge in the Global Ultrasonic Precision Thickness Gauge Market:

Analog Thickness Gauges and Digital Thickness Gauges are two primary types of devices within the Global Ultrasonic Precision Thickness Gauge Market. Analog Thickness Gauges are traditional devices that use mechanical means to measure material thickness. They typically feature a dial or needle that moves in response to the material's thickness, providing a visual representation of the measurement. These gauges are known for their simplicity, durability, and reliability in various industrial applications. They do not require a power source, making them ideal for use in remote or challenging environments. However, they may lack the precision and advanced features of their digital counterparts. On the other hand, Digital Thickness Gauges represent the modern evolution of thickness measurement technology. These devices use electronic sensors and digital displays to provide highly accurate and easy-to-read measurements. Digital gauges often come with additional features such as data storage, connectivity options, and advanced software for analysis and reporting. They are capable of measuring a wide range of materials, including metals, plastics, and composites, with high precision. The digital nature of these gauges allows for more complex measurements and the ability to integrate with other digital systems, enhancing their utility in modern industrial settings. Both analog and digital thickness gauges play crucial roles in the Global Ultrasonic Precision Thickness Gauge Market, catering to different needs and preferences within various industries. While analog gauges offer simplicity and robustness, digital gauges provide advanced features and higher precision, making them suitable for more demanding applications. The choice between analog and digital gauges often depends on the specific requirements of the application, the environment in which they will be used, and the level of precision needed. As technology continues to advance, digital thickness gauges are becoming increasingly popular, but analog gauges still hold a significant place in the market due to their reliability and ease of use.

Municipal, Industrial, Automotive, Others in the Global Ultrasonic Precision Thickness Gauge Market:

The Global Ultrasonic Precision Thickness Gauge Market finds extensive usage across various sectors, including municipal, industrial, automotive, and others. In the municipal sector, these gauges are used for infrastructure maintenance and safety inspections. For instance, they help in assessing the thickness of water pipes, bridges, and other critical structures to ensure they are in good condition and safe for public use. Regular inspections using ultrasonic thickness gauges can prevent potential failures and extend the lifespan of municipal assets. In the industrial sector, ultrasonic precision thickness gauges are indispensable tools for quality control and maintenance. Industries such as manufacturing, aerospace, and energy rely on these devices to measure the thickness of materials like metals, plastics, and composites. Accurate thickness measurements are crucial for ensuring product quality, safety, and compliance with industry standards. In the automotive sector, these gauges are used to measure the thickness of various components, including body panels, engine parts, and other critical elements. Precise measurements are essential for maintaining the structural integrity and performance of vehicles. Ultrasonic thickness gauges help automotive manufacturers and repair shops ensure that parts meet the required specifications and are free from defects. Beyond these specific sectors, ultrasonic precision thickness gauges are also used in other areas such as research and development, education, and healthcare. In research and development, these devices aid in the study of material properties and the development of new materials and products. In educational settings, they are used as teaching tools to demonstrate principles of material science and engineering. In healthcare, ultrasonic thickness gauges can be used for non-invasive measurements of body tissues and other medical applications. Overall, the versatility and precision of ultrasonic thickness gauges make them valuable tools across a wide range of applications, contributing to safety, quality, and innovation in various fields.

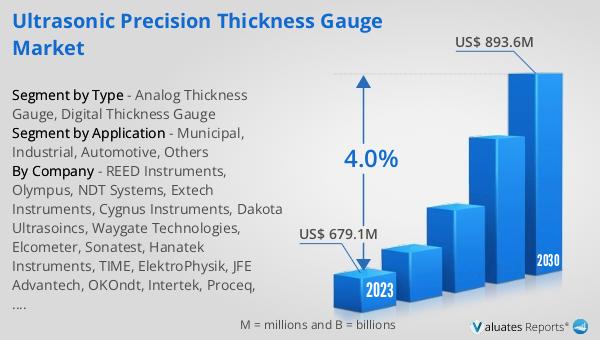

Global Ultrasonic Precision Thickness Gauge Market Outlook:

The global Ultrasonic Precision Thickness Gauge market was valued at US$ 679.1 million in 2023 and is anticipated to reach US$ 893.6 million by 2030, witnessing a CAGR of 4.0% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for ultrasonic precision thickness gauges across various industries. The projected growth reflects the rising importance of accurate and non-destructive testing methods in ensuring the quality and safety of materials and products. As industries continue to evolve and prioritize precision, the adoption of advanced measurement technologies like ultrasonic thickness gauges is expected to rise. This growth trajectory underscores the critical role these devices play in modern industrial practices, from manufacturing and construction to automotive and aerospace sectors. The market's expansion is driven by technological advancements, increasing awareness of the benefits of ultrasonic testing, and the need for reliable and efficient measurement solutions. As a result, the Global Ultrasonic Precision Thickness Gauge Market is poised for significant development, offering numerous opportunities for innovation and application across diverse fields.

| Report Metric | Details |

| Report Name | Ultrasonic Precision Thickness Gauge Market |

| Accounted market size in 2023 | US$ 679.1 million |

| Forecasted market size in 2030 | US$ 893.6 million |

| CAGR | 4.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | REED Instruments, Olympus, NDT Systems, Extech Instruments, Cygnus Instruments, Dakota Ultrasoincs, Waygate Technologies, Elcometer, Sonatest, Hanatek Instruments, TIME, ElektroPhysik, JFE Advantech, OKOndt, Intertek, Proceq, Checkline, YUSHI instruments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |