What is Global Women Nutrition Market?

The Global Women Nutrition Market focuses on providing nutritional products specifically designed to meet the unique health needs of women across different age groups and lifestyles. This market encompasses a wide range of products, including vitamins, minerals, dietary supplements, and functional foods that cater to women's health concerns such as bone health, reproductive health, hormonal balance, and overall well-being. The increasing awareness about the importance of nutrition in maintaining health and preventing diseases has driven the demand for women-specific nutritional products. Additionally, factors such as the rising prevalence of chronic diseases, growing health consciousness, and the increasing disposable income of women have further fueled the growth of this market. Companies operating in this market are continuously innovating and launching new products to cater to the evolving needs of women, making the Global Women Nutrition Market a dynamic and rapidly growing sector.

Sports Nutrition, Additional Supplements, Personalised Nutrition, Others in the Global Women Nutrition Market:

Sports nutrition is a significant segment within the Global Women Nutrition Market, focusing on products that enhance athletic performance, support muscle recovery, and improve overall physical endurance. These products include protein powders, energy bars, hydration drinks, and amino acid supplements. Women engaged in regular physical activities or professional sports often require tailored nutritional support to meet their energy demands and optimize their performance. Additional supplements, another crucial segment, encompass a variety of products such as multivitamins, omega-3 fatty acids, probiotics, and herbal supplements. These supplements aim to fill nutritional gaps, support immune function, and promote overall health. Personalized nutrition is an emerging trend within the market, offering customized dietary recommendations and products based on individual health data, genetic profiles, and lifestyle factors. This approach ensures that women receive nutrition that is specifically tailored to their unique needs, enhancing the effectiveness of the nutritional interventions. Other segments within the Global Women Nutrition Market include products targeting specific health concerns such as prenatal and postnatal nutrition, menopause support, and weight management. These products are designed to address the distinct nutritional requirements of women at different life stages, ensuring optimal health and well-being. The continuous innovation and development of new products in these segments highlight the dynamic nature of the Global Women Nutrition Market, catering to the diverse and evolving needs of women worldwide.

Below 18 Years Old, 18 to 50 Years Old, Above 50 Years Old in the Global Women Nutrition Market:

The usage of products in the Global Women Nutrition Market varies significantly across different age groups, reflecting the unique nutritional needs and health concerns at each life stage. For women below 18 years old, the focus is primarily on supporting growth and development. Nutritional products for this age group often include vitamins and minerals that promote bone health, cognitive development, and immune function. These products are designed to ensure that young women receive the essential nutrients required for healthy growth and to prevent deficiencies that could impact their long-term health. For women aged 18 to 50 years old, the nutritional needs shift towards maintaining overall health, supporting reproductive health, and managing stress and energy levels. Products in this category often include multivitamins, iron supplements, folic acid, and omega-3 fatty acids. These supplements help in maintaining hormonal balance, supporting pregnancy and lactation, and enhancing energy levels to cope with the demands of a busy lifestyle. For women above 50 years old, the focus shifts towards managing age-related health concerns such as bone density loss, cardiovascular health, and cognitive function. Nutritional products for this age group often include calcium and vitamin D supplements for bone health, antioxidants for cognitive support, and omega-3 fatty acids for heart health. These products aim to support healthy aging and improve the quality of life for older women. The diverse range of products available in the Global Women Nutrition Market ensures that women of all ages can find nutritional support tailored to their specific needs, promoting overall health and well-being throughout their lives.

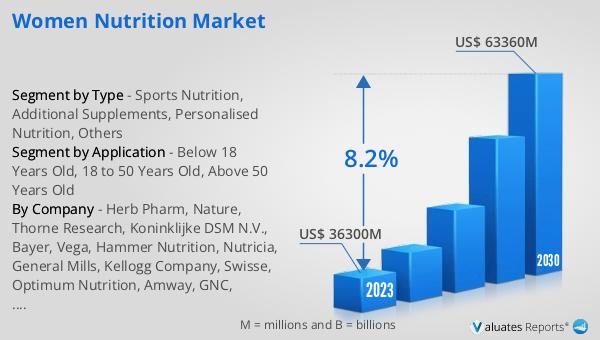

Global Women Nutrition Market Outlook:

The global Women Nutrition market was valued at US$ 36,300 million in 2023 and is anticipated to reach US$ 63,360 million by 2030, witnessing a CAGR of 8.2% during the forecast period 2024-2030. This significant growth reflects the increasing awareness and demand for nutritional products specifically designed for women. The market's expansion is driven by factors such as the rising prevalence of chronic diseases, growing health consciousness among women, and the increasing disposable income that allows for greater spending on health and wellness products. Companies in this market are continuously innovating and launching new products to meet the evolving needs of women, further fueling the market's growth. The projected growth rate underscores the dynamic nature of the Global Women Nutrition Market and its potential to significantly impact women's health and well-being worldwide.

| Report Metric | Details |

| Report Name | Women Nutrition Market |

| Accounted market size in 2023 | US$ 36300 million |

| Forecasted market size in 2030 | US$ 63360 million |

| CAGR | 8.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Herb Pharm, Nature, Thorne Research, Koninklijke DSM N.V., Bayer, Vega, Hammer Nutrition, Nutricia, General Mills, Kellogg Company, Swisse, Optimum Nutrition, Amway, GNC, Danone, Herbalife, Abbott Nutrition, Unilever, ADM, Nestle, Gaia Herbs, NOW Foods, Glanbia Nutritionals, BellRing Brands, Cellucor, Xiwang Foodstuffs, Clif Bar, CytoSport |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |