What is Global Corrosion Under Insulation (CUI) Monitoring Equipment Market?

The Global Corrosion Under Insulation (CUI) Monitoring Equipment Market refers to the industry focused on the development, production, and distribution of devices and systems designed to detect and monitor corrosion that occurs under insulation materials. Corrosion under insulation is a significant issue in various industries, as it can lead to severe structural damage and operational inefficiencies if not properly managed. This market encompasses a range of technologies and solutions aimed at identifying and mitigating the effects of CUI, thereby ensuring the longevity and safety of insulated equipment and infrastructure. The market includes various types of monitoring equipment, such as ultrasonic testing devices, pulsed eddy current systems, radiography tools, and other advanced technologies. These tools are essential for industries that rely heavily on insulated pipelines, tanks, and other equipment, as they help in maintaining the integrity and performance of these assets. The global CUI monitoring equipment market is driven by the increasing need for effective corrosion management solutions, advancements in monitoring technologies, and the growing awareness of the economic and safety implications of CUI.

Ultrasonics, Pulsed Eddy Current, X-rays or Radiography, Others in the Global Corrosion Under Insulation (CUI) Monitoring Equipment Market:

Ultrasonics, Pulsed Eddy Current, X-rays or Radiography, and other technologies play a crucial role in the Global Corrosion Under Insulation (CUI) Monitoring Equipment Market. Ultrasonic testing is a non-destructive method that uses high-frequency sound waves to detect flaws and measure the thickness of materials. This technology is highly effective in identifying corrosion under insulation without the need to remove the insulation, making it a cost-effective and efficient solution. Pulsed Eddy Current (PEC) is another non-destructive testing method that uses electromagnetic fields to detect corrosion. PEC is particularly useful for inspecting ferromagnetic materials and can penetrate thick insulation layers, providing accurate and reliable data on the condition of the underlying metal. X-rays or Radiography is a well-established technique that uses X-rays to create images of the internal structure of materials. This method is highly effective in detecting corrosion and other defects, but it requires specialized equipment and trained personnel to operate. Other technologies used in CUI monitoring include infrared thermography, which detects temperature variations on the surface of insulated equipment, and fiber optic sensors, which provide real-time monitoring of corrosion and other structural changes. Each of these technologies has its own advantages and limitations, and the choice of technology depends on factors such as the type of material being inspected, the thickness of the insulation, and the specific requirements of the application. The integration of these technologies into comprehensive CUI monitoring systems allows for continuous and accurate assessment of the condition of insulated equipment, helping to prevent costly repairs and downtime. The advancements in these technologies have significantly improved the ability to detect and monitor CUI, providing industries with the tools they need to maintain the integrity and performance of their assets.

Oil & Gas, Marine, Chemical & Petrochemical, Energy & Power, Food Processing Industries, Others in the Global Corrosion Under Insulation (CUI) Monitoring Equipment Market:

The usage of Global Corrosion Under Insulation (CUI) Monitoring Equipment Market spans across various industries, including Oil & Gas, Marine, Chemical & Petrochemical, Energy & Power, and Food Processing Industries, among others. In the Oil & Gas industry, CUI monitoring equipment is essential for maintaining the integrity of pipelines, storage tanks, and other insulated equipment. The harsh operating conditions and the presence of corrosive substances make this industry particularly susceptible to CUI, and effective monitoring is crucial for preventing leaks, spills, and other safety hazards. In the Marine industry, CUI monitoring equipment is used to inspect and maintain the structural integrity of ships, offshore platforms, and other marine structures. The constant exposure to saltwater and other corrosive elements makes these structures highly vulnerable to CUI, and regular monitoring is necessary to ensure their safety and longevity. In the Chemical & Petrochemical industry, CUI monitoring equipment is used to inspect and maintain the integrity of insulated pipes, reactors, and other equipment that handle corrosive chemicals. The presence of aggressive chemical environments makes this industry particularly prone to CUI, and effective monitoring is essential for preventing equipment failure and ensuring safe operations. In the Energy & Power industry, CUI monitoring equipment is used to inspect and maintain the integrity of insulated boilers, turbines, and other equipment. The high temperatures and pressures involved in power generation make this industry susceptible to CUI, and regular monitoring is necessary to ensure the reliability and efficiency of the equipment. In the Food Processing industry, CUI monitoring equipment is used to inspect and maintain the integrity of insulated pipes, tanks, and other equipment that handle food products. The presence of moisture and other corrosive elements makes this industry vulnerable to CUI, and effective monitoring is essential for ensuring the safety and quality of the food products. Other industries that use CUI monitoring equipment include pharmaceuticals, water treatment, and manufacturing, among others. The widespread usage of CUI monitoring equipment across these industries highlights the importance of effective corrosion management in maintaining the integrity and performance of insulated equipment.

Global Corrosion Under Insulation (CUI) Monitoring Equipment Market Outlook:

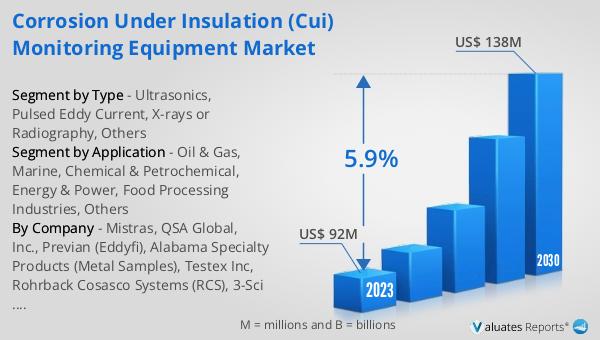

The global Corrosion Under Insulation (CUI) Monitoring Equipment market was valued at US$ 92 million in 2023 and is anticipated to reach US$ 138 million by 2030, witnessing a CAGR of 5.9% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for effective corrosion management solutions across various industries. The rising awareness of the economic and safety implications of CUI, coupled with advancements in monitoring technologies, is expected to fuel the growth of this market. The adoption of CUI monitoring equipment is becoming increasingly critical as industries strive to maintain the integrity and performance of their insulated equipment and infrastructure. The market's growth is also supported by the stringent regulations and standards imposed by regulatory bodies to ensure the safety and reliability of industrial operations. The continuous development of innovative and cost-effective monitoring solutions is expected to further drive the adoption of CUI monitoring equipment in the coming years. The market's expansion is also attributed to the growing investments in infrastructure development and maintenance, particularly in emerging economies. As industries continue to recognize the importance of proactive corrosion management, the demand for advanced CUI monitoring equipment is expected to rise, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | Corrosion Under Insulation (CUI) Monitoring Equipment Market |

| Accounted market size in 2023 | US$ 92 million |

| Forecasted market size in 2030 | US$ 138 million |

| CAGR | 5.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mistras, QSA Global, Inc., Previan (Eddyfi), Alabama Specialty Products (Metal Samples), Testex Inc, Rohrback Cosasco Systems (RCS), 3-Sci Limited, CorrosionRADAR, iSensPro, Maxwell NDT |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |