What is Global Vertical Ring Pulsating High Gradient Magnetic Separators Market?

The Global Vertical Ring Pulsating High Gradient Magnetic Separators Market is a specialized segment within the broader magnetic separation industry. These separators are advanced machines designed to separate fine and weakly magnetic particles from a mixture using a high-gradient magnetic field. The "vertical ring" design refers to the orientation of the magnetic field, which is vertical, and the "pulsating" aspect indicates that the magnetic field is not constant but varies in intensity. This pulsation helps in preventing clogging and ensures a more efficient separation process. These machines are particularly useful in industries where the purity of the material is crucial, such as in the mining of metallic and rare earth minerals, as well as in the treatment of industrial wastewater. The high-gradient magnetic field allows for the separation of particles that would otherwise be difficult to isolate using traditional magnetic separators. This technology is essential for improving the quality of the final product and for reducing waste, making it a valuable tool in various industrial applications.

DLS, HLGC in the Global Vertical Ring Pulsating High Gradient Magnetic Separators Market:

The Global Vertical Ring Pulsating High Gradient Magnetic Separators Market includes technologies like DLS (Dynamic Light Scattering) and HLGC (High-Gradient Magnetic Capture). DLS is a technique used to measure the size distribution of small particles in suspension or polymers in solution. In the context of magnetic separators, DLS can be used to analyze the size and distribution of particles that are being separated. This information is crucial for optimizing the separation process, as it allows operators to adjust the magnetic field strength and pulsation frequency to achieve the best results. On the other hand, HLGC refers to the ability of the magnetic separator to capture particles using a high-gradient magnetic field. This is particularly important for separating fine and weakly magnetic particles, which would otherwise be difficult to isolate. The combination of DLS and HLGC technologies in vertical ring pulsating high gradient magnetic separators ensures a high level of precision and efficiency in the separation process. These technologies are essential for industries that require high-purity materials, such as the mining of rare earth minerals and the treatment of industrial wastewater. By using DLS and HLGC, these separators can achieve a higher level of separation efficiency, reducing waste and improving the quality of the final product.

Metallic Minerals, Rare Earth Minerals, Industrial Wastewater Treatment, Coal, Others in the Global Vertical Ring Pulsating High Gradient Magnetic Separators Market:

The Global Vertical Ring Pulsating High Gradient Magnetic Separators Market finds extensive usage in various areas, including metallic minerals, rare earth minerals, industrial wastewater treatment, coal, and others. In the mining of metallic minerals, these separators are used to isolate valuable metals from the ore. The high-gradient magnetic field allows for the separation of fine and weakly magnetic particles, which are often present in metallic ores. This results in a higher purity of the extracted metal, improving the overall efficiency of the mining process. In the case of rare earth minerals, the separators are used to isolate rare earth elements, which are essential for various high-tech applications. The high-gradient magnetic field ensures that even the finest particles are separated, resulting in a high-purity product. In industrial wastewater treatment, these separators are used to remove magnetic particles from the wastewater. This is crucial for industries that produce wastewater containing fine and weakly magnetic particles, as it helps in reducing the environmental impact of the wastewater. In the coal industry, these separators are used to remove impurities from the coal, improving its quality and efficiency as a fuel source. The separators are also used in other industries where the separation of fine and weakly magnetic particles is essential. Overall, the Global Vertical Ring Pulsating High Gradient Magnetic Separators Market plays a crucial role in improving the efficiency and quality of various industrial processes.

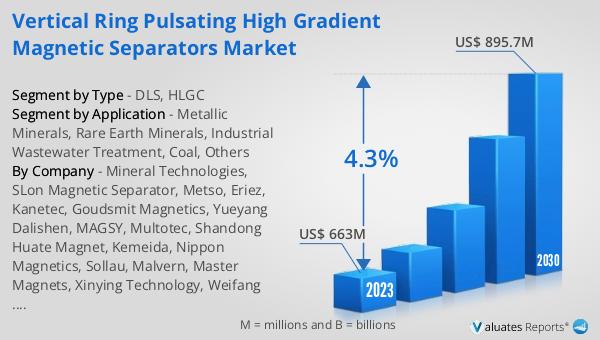

Global Vertical Ring Pulsating High Gradient Magnetic Separators Market Outlook:

The global market for Vertical Ring Pulsating High Gradient Magnetic Separators was valued at approximately US$ 663 million in 2023. It is projected to grow significantly, reaching an estimated value of US$ 895.7 million by the year 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. This indicates a steady increase in demand for these advanced magnetic separators across various industries. The rising need for high-purity materials and efficient separation processes is driving the market growth. Industries such as mining, wastewater treatment, and coal are increasingly adopting these separators to improve the quality of their products and reduce waste. The vertical ring design and pulsating magnetic field of these separators make them highly efficient in separating fine and weakly magnetic particles, which are often challenging to isolate using traditional methods. As a result, the Global Vertical Ring Pulsating High Gradient Magnetic Separators Market is expected to witness substantial growth in the coming years, driven by advancements in technology and increasing industrial applications.

| Report Metric | Details |

| Report Name | Vertical Ring Pulsating High Gradient Magnetic Separators Market |

| Accounted market size in 2023 | US$ 663 million |

| Forecasted market size in 2030 | US$ 895.7 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mineral Technologies, SLon Magnetic Separator, Metso, Eriez, Kanetec, Goudsmit Magnetics, Yueyang Dalishen, MAGSY, Multotec, Shandong Huate Magnet, Kemeida, Nippon Magnetics, Sollau, Malvern, Master Magnets, Xinying Technology, Weifang Guote Mining Equipment Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |