What is Upset Testing Machine - Global Market?

The Upset Testing Machine is a specialized piece of equipment used in various industries to evaluate the mechanical properties of materials, particularly their resistance to deformation under compressive forces. This machine plays a crucial role in quality control and research and development processes by providing precise data on material strength and ductility. The global market for Upset Testing Machines is driven by the increasing demand for high-quality materials in sectors such as automotive, aerospace, and construction. These machines are essential for ensuring that materials can withstand the stresses they will encounter in real-world applications. The market is characterized by a range of machines that vary in terms of automation, capacity, and technological sophistication, catering to the diverse needs of industries worldwide. As industries continue to innovate and develop new materials, the demand for advanced testing equipment like the Upset Testing Machine is expected to grow, making it a vital component of modern manufacturing and engineering processes. The global market for these machines was valued at approximately US$ 13 million in 2023 and is projected to reach US$ 17 million by 2030, reflecting a steady growth trajectory driven by technological advancements and increasing industrial applications.

Semi-automatic, Automatic in the Upset Testing Machine - Global Market:

In the realm of Upset Testing Machines, the market is segmented into semi-automatic and automatic machines, each offering distinct advantages and catering to different industrial needs. Semi-automatic Upset Testing Machines require some level of human intervention for operation, making them suitable for environments where flexibility and manual oversight are necessary. These machines are often favored by smaller manufacturing units or research facilities where the volume of testing is moderate, and the focus is on precision and adaptability. Operators can manually adjust settings and oversee the testing process, allowing for a more hands-on approach to material testing. This can be particularly beneficial in research settings where experimental conditions may vary, and a more tailored approach is required. On the other hand, automatic Upset Testing Machines are designed for high-volume testing environments where efficiency and consistency are paramount. These machines are equipped with advanced software and sensors that allow for fully automated testing processes, minimizing the need for human intervention. This automation not only speeds up the testing process but also enhances accuracy and repeatability, making them ideal for large-scale manufacturing operations where uniformity and speed are critical. Automatic machines are often integrated into production lines, providing real-time data that can be used to make immediate adjustments to manufacturing processes, thereby improving overall product quality and reducing waste. The choice between semi-automatic and automatic machines often depends on the specific requirements of the industry, the scale of operations, and the level of precision needed. As industries continue to evolve, there is a growing trend towards automation, driven by the need for increased efficiency and the ability to handle larger volumes of testing without compromising on accuracy. This shift is reflected in the global market for Upset Testing Machines, where automatic machines are gaining traction, particularly in sectors such as automotive and aerospace, where the demand for high-quality, reliable materials is paramount. Despite the growing preference for automation, semi-automatic machines still hold a significant share of the market, particularly in regions where labor costs are lower, and there is a greater emphasis on manual oversight. The balance between these two types of machines is indicative of the diverse needs of the global market, highlighting the importance of flexibility and adaptability in material testing processes. As technology continues to advance, it is likely that both semi-automatic and automatic Upset Testing Machines will continue to evolve, incorporating new features and capabilities that enhance their functionality and appeal to a broader range of industries.

Functional Testing, Security Testing, Usability Testing, Stress Testing in the Upset Testing Machine - Global Market:

Upset Testing Machines are utilized in various testing scenarios, including functional testing, security testing, usability testing, and stress testing, each serving a unique purpose in evaluating material performance. In functional testing, these machines are used to assess whether materials meet specified performance criteria under normal operating conditions. This involves subjecting materials to compressive forces to determine their strength, ductility, and overall suitability for intended applications. Functional testing is crucial in industries such as automotive and aerospace, where materials must meet stringent standards to ensure safety and reliability. Security testing, on the other hand, involves evaluating the ability of materials to withstand tampering or unauthorized access. While not a direct application of Upset Testing Machines, the data obtained from these machines can inform security testing by providing insights into material vulnerabilities and potential points of failure. Usability testing focuses on the ease of use and practicality of materials in real-world applications. Upset Testing Machines contribute to this by ensuring that materials can withstand the stresses they will encounter during everyday use, thereby enhancing their usability and longevity. Stress testing is perhaps the most direct application of Upset Testing Machines, as it involves subjecting materials to extreme conditions to evaluate their performance under stress. This type of testing is essential for identifying the limits of material performance and ensuring that they can withstand unexpected or extreme conditions. In industries such as construction and manufacturing, stress testing is vital for ensuring that materials can endure the rigors of their intended applications without failure. Overall, the use of Upset Testing Machines in these testing scenarios underscores their importance in ensuring material quality and performance across a wide range of industries. By providing accurate and reliable data on material properties, these machines play a critical role in the development and production of high-quality, durable products that meet the demands of modern industry.

Upset Testing Machine - Global Market Outlook:

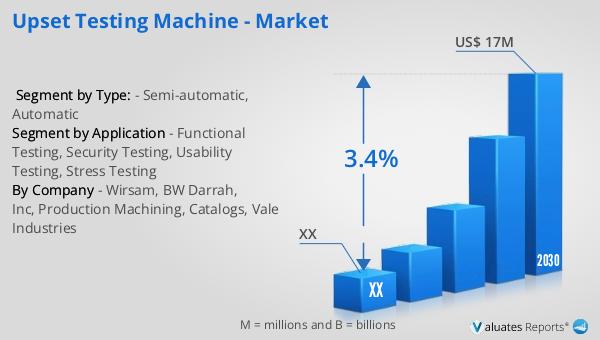

The global market for Upset Testing Machines was valued at approximately US$ 13 million in 2023, with projections indicating a growth to US$ 17 million by 2030. This growth reflects a compound annual growth rate (CAGR) of 3.4% over the forecast period from 2024 to 2030. This steady increase in market size is indicative of the rising demand for advanced material testing solutions across various industries. In North America, the market for Upset Testing Machines is also expected to experience growth, although specific figures for this region were not provided. The anticipated growth in this region can be attributed to the strong presence of industries such as automotive, aerospace, and construction, which require reliable and efficient material testing solutions. The adoption of Upset Testing Machines in these industries is driven by the need for high-quality materials that can withstand the demands of modern manufacturing and engineering processes. As industries continue to innovate and develop new materials, the demand for advanced testing equipment like the Upset Testing Machine is expected to grow, making it a vital component of modern manufacturing and engineering processes. The market outlook for Upset Testing Machines highlights the importance of these machines in ensuring material quality and performance, as well as their role in supporting the development of new materials and technologies.

| Report Metric | Details |

| Report Name | Upset Testing Machine - Market |

| Forecasted market size in 2030 | US$ 17 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Wirsam, BW Darrah, Inc, Production Machining, Catalogs, Vale Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |