What is Laser Plastic Welding Lines - Global Market?

Laser plastic welding lines represent a specialized segment within the broader welding industry, focusing on the precise and efficient joining of plastic components using laser technology. This method has gained traction globally due to its ability to produce clean, strong, and aesthetically pleasing welds without the need for additional materials or extensive post-processing. The process involves directing a laser beam onto the plastic parts to be joined, causing the material to melt and fuse together upon cooling. This technique is particularly advantageous for applications requiring high precision and minimal thermal distortion, making it ideal for industries such as automotive, medical devices, and electronics. The global market for laser plastic welding lines is driven by the increasing demand for lightweight and durable materials, advancements in laser technology, and the growing emphasis on automation and efficiency in manufacturing processes. As industries continue to seek innovative solutions to enhance product quality and production speed, laser plastic welding lines are poised to play a crucial role in meeting these evolving needs. The market's growth is further supported by the rising adoption of laser welding in emerging economies, where manufacturers are increasingly recognizing the benefits of this advanced technology.

Fiber Laser Welding System, Solid-State Laser Welding System, Semiconductor Laser Welding System, CO2 Laser Welding System in the Laser Plastic Welding Lines - Global Market:

The laser plastic welding market encompasses various systems, each with unique characteristics and applications. Fiber laser welding systems are renowned for their high efficiency and precision, utilizing a fiber optic cable to deliver the laser beam. This system is particularly effective for intricate welding tasks, offering excellent beam quality and energy efficiency. Solid-state laser welding systems, on the other hand, use a solid gain medium, such as a crystal or glass, to generate the laser beam. These systems are valued for their robustness and ability to handle high-power applications, making them suitable for heavy-duty industrial tasks. Semiconductor laser welding systems, also known as diode lasers, are compact and versatile, offering a cost-effective solution for a range of welding applications. They are particularly useful in scenarios where space is limited, and flexibility is required. CO2 laser welding systems utilize carbon dioxide gas to produce the laser beam, known for their ability to cut and weld a wide variety of materials, including plastics. These systems are favored for their high power output and ability to handle large-scale welding tasks. Each of these systems plays a vital role in the laser plastic welding market, catering to diverse industrial needs and contributing to the overall growth and innovation within the sector. As industries continue to evolve and demand more sophisticated welding solutions, these systems are expected to adapt and advance, offering even greater capabilities and efficiencies. The choice of system often depends on the specific requirements of the application, including the type of material, desired weld quality, and production speed. As technology continues to advance, the integration of features such as real-time monitoring and automation is becoming increasingly common, further enhancing the capabilities and appeal of laser plastic welding systems. This ongoing innovation is essential for meeting the ever-changing demands of industries and maintaining the competitiveness of laser plastic welding in the global market.

Automotive, Medical Device, Electrical & Electronics, Others in the Laser Plastic Welding Lines - Global Market:

Laser plastic welding lines have found significant applications across various industries, each benefiting from the unique advantages offered by this technology. In the automotive sector, laser plastic welding is used to join components such as fuel tanks, sensors, and interior parts, where precision and strength are paramount. The ability to produce clean and strong welds without damaging surrounding materials makes it an ideal choice for automotive manufacturers seeking to enhance vehicle performance and safety. In the medical device industry, laser plastic welding is employed to assemble products like catheters, filters, and diagnostic equipment, where hygiene and precision are critical. The non-contact nature of laser welding minimizes the risk of contamination, ensuring that medical devices meet stringent safety and quality standards. The electrical and electronics industry also benefits from laser plastic welding, particularly in the production of components such as connectors, sensors, and housings. The precision and reliability of laser welding ensure that electronic components are securely joined, enhancing their performance and longevity. Beyond these sectors, laser plastic welding is used in various other applications, including consumer goods, packaging, and textiles, where it offers advantages such as design flexibility, reduced material waste, and improved product aesthetics. As industries continue to innovate and seek more efficient manufacturing processes, the adoption of laser plastic welding lines is expected to grow, driven by the need for high-quality, reliable, and cost-effective solutions. The versatility and adaptability of laser plastic welding make it a valuable tool for manufacturers looking to stay competitive in an increasingly demanding market.

Laser Plastic Welding Lines - Global Market Outlook:

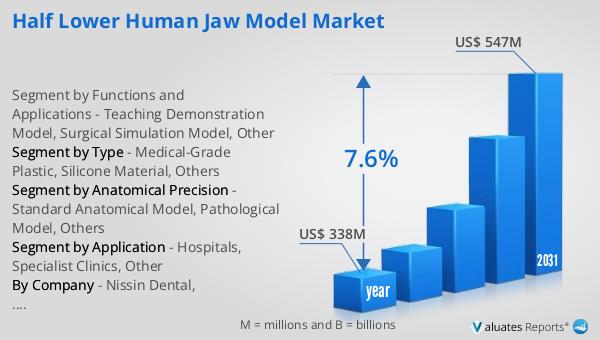

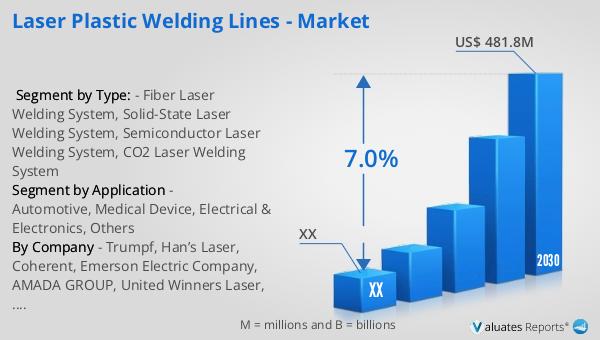

The global market for laser plastic welding lines was valued at approximately $296.2 million in 2023, with projections indicating a growth to around $481.8 million by 2030. This represents a compound annual growth rate (CAGR) of 7.0% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for advanced welding solutions across various industries, including automotive, medical devices, and electronics. In North America, the market for laser plastic welding lines is also expected to experience significant growth, although specific figures for this region were not provided. The anticipated expansion in this market is attributed to the rising adoption of laser welding technology, driven by the need for precision, efficiency, and cost-effectiveness in manufacturing processes. As industries continue to evolve and seek innovative solutions to enhance product quality and production speed, the demand for laser plastic welding lines is expected to increase, further supporting the market's growth. The ongoing advancements in laser technology, coupled with the growing emphasis on automation and efficiency, are likely to play a crucial role in shaping the future of the laser plastic welding market.

| Report Metric | Details |

| Report Name | Laser Plastic Welding Lines - Market |

| Forecasted market size in 2030 | US$ 481.8 million |

| CAGR | 7.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Trumpf, Han’s Laser, Coherent, Emerson Electric Company, AMADA GROUP, United Winners Laser, IPG Photonics, Chutian Laser, Jenoptik, LPKF Laser & Electronics, Dukane Corporatio, Panasonic, SONIMAT, Mecco, IPTE Factory Automation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |