What is Cemented Carbide Ball - Global Market?

Cemented carbide balls are a crucial component in various industrial applications due to their exceptional hardness, wear resistance, and ability to withstand extreme conditions. These balls are made from a composite material consisting of tungsten carbide particles bonded together with a metallic binder, typically cobalt. The global market for cemented carbide balls is driven by their extensive use in industries such as automotive, aerospace, oil and gas, and manufacturing. These balls are essential in applications where high precision and durability are required, such as in bearings, ball screws, valves, and flowmeters. The demand for cemented carbide balls is expected to grow as industries continue to seek materials that offer superior performance and longevity. The market is characterized by a diverse range of products, catering to different industrial needs, and is supported by advancements in manufacturing technologies that enhance the quality and performance of these balls. As industries evolve and new applications emerge, the cemented carbide ball market is poised for continued growth, driven by the need for reliable and efficient components in high-stress environments.

84.0-85.5, 86.0-87.5, 88.0-89.5, 90.0-91.5, ≥92.0 in the Cemented Carbide Ball - Global Market:

The cemented carbide ball market is segmented based on the hardness levels of the balls, which are typically measured on the Rockwell scale. The categories include 84.0-85.5, 86.0-87.5, 88.0-89.5, 90.0-91.5, and ≥92.0. Each of these hardness levels corresponds to specific applications and performance requirements. Balls with a hardness of 84.0-85.5 are generally used in applications where moderate wear resistance is sufficient, such as in less demanding environments or where cost considerations are a priority. As the hardness increases to 86.0-87.5, the balls offer better wear resistance and are suitable for more demanding applications, such as in certain types of bearings and mechanical components that experience moderate stress. The 88.0-89.5 hardness range is ideal for applications requiring a balance between toughness and wear resistance, making them suitable for use in ball screws and other precision components. Balls with a hardness of 90.0-91.5 are designed for high-stress applications where superior wear resistance is critical, such as in valves and flowmeters that operate under high pressure and temperature conditions. Finally, balls with a hardness of ≥92.0 represent the pinnacle of performance, offering exceptional wear resistance and durability for the most demanding applications, such as in aerospace and high-performance automotive components. These balls are often used in environments where failure is not an option, and the cost of downtime or maintenance is prohibitively high. The choice of hardness level depends on the specific requirements of the application, including factors such as load, speed, temperature, and environmental conditions. Manufacturers continue to innovate in this space, developing new materials and processes to enhance the performance of cemented carbide balls across all hardness levels. This ongoing innovation is crucial to meeting the evolving needs of industries that rely on these components for critical applications.

Bearings, Ball Screws, Valves, Flowmeters, Other in the Cemented Carbide Ball - Global Market:

Cemented carbide balls are used extensively in various applications due to their unique properties. In bearings, these balls provide exceptional wear resistance and durability, which are critical for maintaining the smooth operation of machinery. Bearings are used in a wide range of industries, including automotive, aerospace, and manufacturing, where they play a vital role in reducing friction and supporting rotational or linear movement. The use of cemented carbide balls in bearings ensures long service life and reliable performance, even under high loads and speeds. In ball screws, cemented carbide balls are used to convert rotational motion into linear motion with high precision and efficiency. These components are essential in applications such as CNC machines, robotics, and other automated systems where accuracy and repeatability are paramount. The hardness and wear resistance of cemented carbide balls make them ideal for use in ball screws, where they can withstand the high forces and repetitive motion involved. Valves are another critical application for cemented carbide balls, particularly in industries such as oil and gas, chemical processing, and power generation. These balls are used in ball valves, which control the flow of fluids through a system. The ability of cemented carbide balls to resist wear and corrosion ensures reliable operation and long service life, even in harsh environments. Flowmeters, which measure the flow rate of liquids or gases, also benefit from the use of cemented carbide balls. These balls are used in the moving parts of flowmeters, where their durability and precision contribute to accurate measurements and reliable performance. Other applications for cemented carbide balls include use in precision instruments, cutting tools, and various industrial machinery where high performance and reliability are required. The versatility and superior properties of cemented carbide balls make them an indispensable component in many industries, driving demand and innovation in the global market.

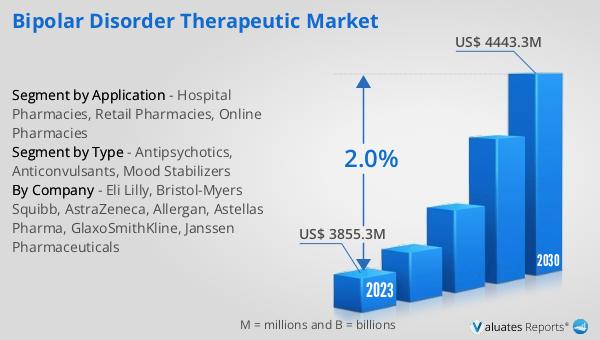

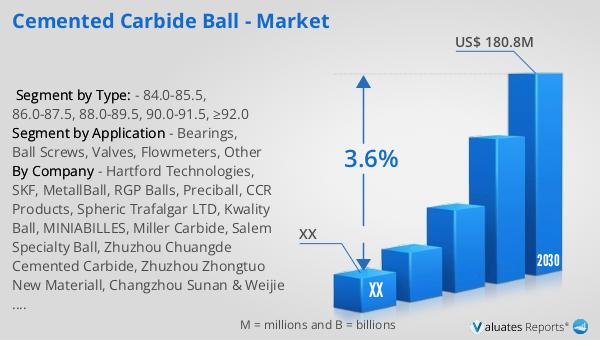

Cemented Carbide Ball - Global Market Outlook:

The global market for cemented carbide balls was valued at approximately $143.6 million in 2023. It is projected to grow to a revised size of $180.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-performance materials in various industrial applications, as well as advancements in manufacturing technologies that enhance the quality and performance of cemented carbide balls. The North American market for cemented carbide balls was valued at $ million in 2023 and is expected to reach $ million by 2030, with a CAGR of % during the forecast period from 2024 through 2030. This growth is supported by the strong presence of key industries such as automotive, aerospace, and oil and gas in the region, which rely heavily on cemented carbide balls for critical applications. The market outlook for cemented carbide balls is positive, with continued growth expected as industries seek materials that offer superior performance and longevity. The ongoing development of new materials and processes will further enhance the capabilities of cemented carbide balls, driving demand and innovation in the global market.

| Report Metric | Details |

| Report Name | Cemented Carbide Ball - Market |

| Forecasted market size in 2030 | US$ 180.8 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hartford Technologies, SKF, MetallBall, RGP Balls, Preciball, CCR Products, Spheric Trafalgar LTD, Kwality Ball, MINIABILLES, Miller Carbide, Salem Specialty Ball, Zhuzhou Chuangde Cemented Carbide, Zhuzhou Zhongtuo New Materiall, Changzhou Sunan & Weijie Steel Balls, Zhuzhou Jat cemented carbide |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |