What is Pressure Vacuum Relief Valve - Global Market?

Pressure Vacuum Relief Valves (PVRVs) are essential components in various industrial applications, designed to protect storage tanks and process systems from excessive pressure and vacuum conditions. These valves ensure that tanks do not rupture due to overpressure or implode due to vacuum conditions, thereby maintaining the integrity and safety of the storage systems. The global market for PVRVs is driven by the increasing demand for safety and efficiency in industries such as oil and gas, chemicals, and pharmaceuticals. As industries continue to expand and modernize, the need for reliable pressure management solutions becomes more critical. PVRVs are available in various sizes and materials to cater to different industrial requirements, ensuring compatibility with a wide range of substances and environmental conditions. The market is characterized by technological advancements aimed at improving the performance and reliability of these valves, as well as regulatory standards that mandate their use in certain applications. As a result, the global market for Pressure Vacuum Relief Valves is poised for steady growth, driven by the ongoing industrialization and the need for enhanced safety measures in process industries.

Low Pressure Valve, Medium Pressure Valve, High Pressure Valve in the Pressure Vacuum Relief Valve - Global Market:

Pressure Vacuum Relief Valves are categorized based on the pressure levels they are designed to handle: low pressure, medium pressure, and high pressure. Low-pressure valves are typically used in applications where the pressure differential is minimal, such as in storage tanks for liquids that are not highly volatile. These valves are crucial in preventing the collapse of tanks due to vacuum conditions and ensuring that the pressure does not exceed safe limits. They are often made from materials that can withstand mild chemical exposure and are designed to operate efficiently at lower pressure ranges. Medium-pressure valves are used in more demanding applications where the pressure conditions are moderate. These valves are essential in industries where the stored substances may have a higher volatility or where the process conditions require a more robust pressure management solution. Medium-pressure valves are constructed from materials that offer greater resistance to chemical exposure and mechanical stress, ensuring durability and reliability in more challenging environments. High-pressure valves are designed for the most demanding applications, where the pressure conditions are extreme. These valves are critical in industries such as oil and gas, where the stored substances are highly volatile and the risk of overpressure is significant. High-pressure valves are made from high-strength materials that can withstand severe chemical exposure and mechanical stress, ensuring that they can operate reliably under the most challenging conditions. The global market for Pressure Vacuum Relief Valves is driven by the diverse needs of these different pressure categories, with each type of valve serving a specific purpose in maintaining the safety and integrity of industrial processes. As industries continue to evolve and the demand for more efficient and reliable pressure management solutions grows, the market for these valves is expected to expand, offering opportunities for innovation and development in valve technology.

Oil and Gas, Chemical, Power Generation, Paper Industry, Food and Beverages, Pharmaceuticals, Others in the Pressure Vacuum Relief Valve - Global Market:

Pressure Vacuum Relief Valves play a crucial role in various industries, ensuring the safety and efficiency of operations by preventing overpressure and vacuum conditions in storage tanks and process systems. In the oil and gas industry, these valves are essential for maintaining the integrity of storage tanks and pipelines, which are often subjected to extreme pressure conditions. They help prevent accidents and environmental hazards by ensuring that the pressure within the tanks remains within safe limits. In the chemical industry, PVRVs are used to protect storage tanks containing volatile chemicals, preventing the release of hazardous substances into the environment. These valves are designed to withstand the corrosive nature of many chemicals, ensuring long-term reliability and safety. In power generation, PVRVs are used to manage pressure in systems that store and transport fuels and other critical substances. They help maintain the efficiency and safety of power plants by preventing pressure-related incidents that could lead to downtime or equipment damage. The paper industry relies on PVRVs to manage pressure in storage tanks and process systems, ensuring the safe handling of chemicals and other substances used in paper production. In the food and beverages industry, these valves are used to maintain the quality and safety of products by preventing contamination and spoilage due to pressure fluctuations. PVRVs are designed to meet strict hygiene standards, ensuring that they do not compromise the quality of food and beverage products. In the pharmaceutical industry, PVRVs are used to protect storage tanks and process systems that handle sensitive and valuable substances. These valves help maintain the integrity of pharmaceutical products by preventing contamination and ensuring that the pressure conditions remain within safe limits. Other industries, such as water treatment and waste management, also rely on PVRVs to ensure the safe and efficient operation of their systems. The global market for Pressure Vacuum Relief Valves is driven by the diverse needs of these industries, with each sector requiring specific solutions to meet their unique pressure management challenges. As industries continue to grow and evolve, the demand for reliable and efficient PVRVs is expected to increase, driving innovation and development in valve technology.

Pressure Vacuum Relief Valve - Global Market Outlook:

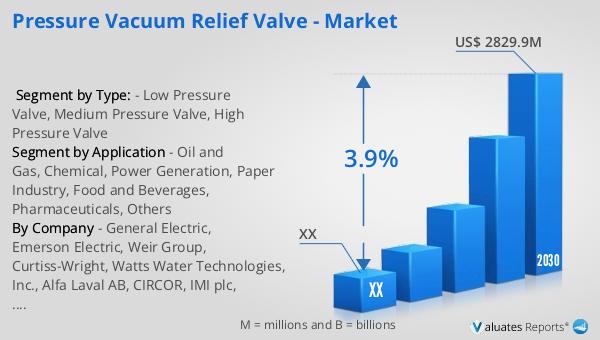

The global market for Pressure Vacuum Relief Valves was valued at approximately $2,150 million in 2023, with projections indicating a growth to around $2,829.9 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2024 to 2030. This steady growth is indicative of the increasing demand for safety and efficiency in various industrial applications, where these valves play a critical role. In North America, the market for Pressure Vacuum Relief Valves is also expected to experience growth, although specific figures for 2023 and 2030 are not provided. The growth in this region is driven by the ongoing industrialization and modernization of industries, as well as the stringent regulatory standards that mandate the use of these valves in certain applications. The market outlook for Pressure Vacuum Relief Valves highlights the importance of these components in ensuring the safety and efficiency of industrial processes, as well as the opportunities for innovation and development in valve technology. As industries continue to expand and evolve, the demand for reliable and efficient pressure management solutions is expected to drive the growth of the global market for Pressure Vacuum Relief Valves.

| Report Metric | Details |

| Report Name | Pressure Vacuum Relief Valve - Market |

| Forecasted market size in 2030 | US$ 2829.9 million |

| CAGR | 3.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | General Electric, Emerson Electric, Weir Group, Curtiss-Wright, Watts Water Technologies, Inc., Alfa Laval AB, CIRCOR, IMI plc, Aalberts, Parker Hannifin, Pentair, Gresswell Valves, LESER GmbH & Co. KG, Flow Safe, GEA AWP Valves, Mercury Manufacturing, Control Devices, AGF Manufacturing, Goetze KG Armaturen, Aquatrol, Wenzhou Sansun Stainless Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |