What is Global Automatic Hot Melt Welding Machines Market?

The Global Automatic Hot Melt Welding Machines Market refers to the worldwide industry focused on the production, distribution, and utilization of machines that use hot melt adhesives to join materials together. These machines are essential in various manufacturing processes where strong, durable bonds are required. Hot melt welding machines operate by heating a thermoplastic adhesive until it melts, then applying it to the materials to be joined. As the adhesive cools, it solidifies, creating a robust bond. This market encompasses a wide range of industries, including automotive, packaging, textiles, and electronics, where precision and efficiency in bonding are crucial. The market is driven by the increasing demand for automation in manufacturing processes, which enhances productivity and reduces labor costs. Additionally, advancements in adhesive technologies and the growing need for high-performance bonding solutions contribute to the market's expansion. The global reach of this market indicates its significance in modern manufacturing, where reliable and efficient bonding methods are essential for product quality and performance.

Fully Automatic Welding Machines, Semi Automatic Welding Machines in the Global Automatic Hot Melt Welding Machines Market:

Fully Automatic Welding Machines and Semi-Automatic Welding Machines are two primary categories within the Global Automatic Hot Melt Welding Machines Market. Fully Automatic Welding Machines are designed to perform welding operations with minimal human intervention. These machines are equipped with advanced sensors, control systems, and software that allow them to execute precise welding tasks autonomously. They are ideal for high-volume production environments where consistency and speed are paramount. Fully automatic machines can handle complex welding processes, ensuring uniformity and reducing the likelihood of human error. They are commonly used in industries such as automotive manufacturing, where precision and efficiency are critical. On the other hand, Semi-Automatic Welding Machines require some level of human involvement. While these machines automate certain aspects of the welding process, such as adhesive application and temperature control, an operator is needed to oversee the operation and make adjustments as necessary. Semi-automatic machines offer a balance between automation and manual control, making them suitable for smaller production runs or applications where flexibility is required. They are often used in industries like packaging and textiles, where the ability to adapt to different materials and product specifications is important. Both types of machines contribute to the overall efficiency and productivity of manufacturing processes, but the choice between fully automatic and semi-automatic depends on the specific needs and scale of the operation. The advancements in technology have led to the development of more sophisticated welding machines that can handle a wider range of materials and applications, further driving the growth of the Global Automatic Hot Melt Welding Machines Market.

Oil & Gas, Water Supply, Chemical Industry, Others in the Global Automatic Hot Melt Welding Machines Market:

The usage of Global Automatic Hot Melt Welding Machines Market spans across various industries, including Oil & Gas, Water Supply, Chemical Industry, and others. In the Oil & Gas sector, these machines are crucial for the construction and maintenance of pipelines. The strong, durable bonds created by hot melt welding ensure the integrity of pipelines, which is essential for the safe and efficient transport of oil and gas. The ability to automate the welding process also enhances productivity and reduces the risk of human error, which is critical in an industry where safety is paramount. In the Water Supply industry, hot melt welding machines are used to join pipes and fittings, ensuring leak-proof connections that are vital for the distribution of clean water. The reliability and efficiency of these machines help in maintaining the quality and safety of water supply systems. The Chemical Industry also benefits from the use of hot melt welding machines, particularly in the construction of chemical storage tanks and pipelines. The strong bonds created by these machines ensure the containment of hazardous materials, preventing leaks and spills that could have serious environmental and safety implications. Additionally, the automation of the welding process reduces the exposure of workers to hazardous chemicals, enhancing workplace safety. Other industries that utilize hot melt welding machines include automotive, packaging, textiles, and electronics. In the automotive industry, these machines are used for assembling various components, ensuring strong and durable bonds that contribute to the overall safety and performance of vehicles. In the packaging industry, hot melt welding machines are used to create secure seals on packaging materials, ensuring the integrity and safety of packaged goods. The textiles industry uses these machines for bonding fabrics and other materials, enhancing the durability and quality of textile products. In the electronics industry, hot melt welding machines are used to assemble electronic components, ensuring reliable connections that are essential for the performance of electronic devices. The versatility and efficiency of hot melt welding machines make them indispensable in a wide range of applications, driving the growth of the Global Automatic Hot Melt Welding Machines Market.

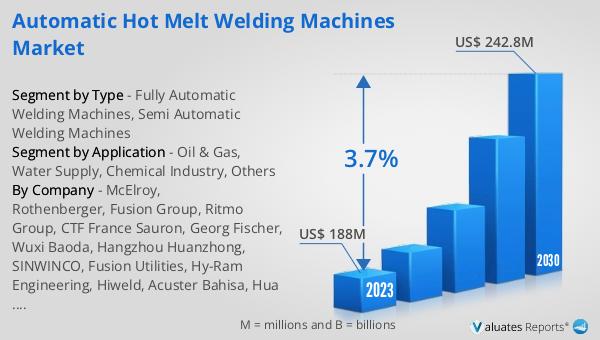

Global Automatic Hot Melt Welding Machines Market Outlook:

The global Automatic Hot Melt Welding Machines market was valued at US$ 188 million in 2023 and is anticipated to reach US$ 242.8 million by 2030, witnessing a CAGR of 3.7% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by increasing demand for automation in manufacturing processes and advancements in adhesive technologies. The projected growth reflects the expanding applications of hot melt welding machines across various industries, including automotive, packaging, textiles, and electronics. The market's valuation in 2023 underscores its significance in the global manufacturing landscape, where efficient and reliable bonding solutions are essential for product quality and performance. The anticipated growth to US$ 242.8 million by 2030 highlights the ongoing advancements in technology and the increasing adoption of automated welding solutions. The CAGR of 3.7% during the forecast period indicates a consistent and sustainable growth rate, driven by the need for high-performance bonding solutions and the benefits of automation in enhancing productivity and reducing labor costs. This market outlook provides valuable insights into the future trends and opportunities in the Global Automatic Hot Melt Welding Machines Market, emphasizing the importance of innovation and technological advancements in driving market growth.

| Report Metric | Details |

| Report Name | Automatic Hot Melt Welding Machines Market |

| Accounted market size in 2023 | US$ 188 million |

| Forecasted market size in 2030 | US$ 242.8 million |

| CAGR | 3.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | McElroy, Rothenberger, Fusion Group, Ritmo Group, CTF France Sauron, Georg Fischer, Wuxi Baoda, Hangzhou Huanzhong, SINWINCO, Fusion Utilities, Hy-Ram Engineering, Hiweld, Acuster Bahisa, Hua Jin Welder, Shandong Chuangming Machinery Equipment Co., LTD, Hebei Mingmai Technology Co., Ltd, Shandong Lechuang Machinery Equipment Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |