What is Pipe Inspection System - Global Market?

Pipe inspection systems are essential tools used globally to ensure the integrity and functionality of pipelines across various industries. These systems are designed to detect and diagnose issues such as blockages, corrosion, leaks, and structural damage within pipes. The global market for pipe inspection systems is driven by the increasing need for regular maintenance and safety checks in industries like oil and gas, water and sewer, manufacturing, and aerospace. With the growing complexity of pipeline networks and the critical role they play in infrastructure, the demand for advanced inspection technologies has surged. These systems employ various methods, including CCTV, ultrasonic, and other advanced technologies, to provide accurate assessments of pipeline conditions. The market is characterized by continuous innovation, with companies investing in research and development to enhance the efficiency and accuracy of inspection tools. As industries strive to minimize downtime and prevent costly repairs, the adoption of pipe inspection systems is expected to rise, making them an indispensable component of modern infrastructure management. The global market for these systems is poised for growth, reflecting the increasing emphasis on safety, reliability, and environmental compliance in pipeline operations.

CCTV, Ultrasonic, Other in the Pipe Inspection System - Global Market:

CCTV, ultrasonic, and other technologies form the backbone of the pipe inspection system market, each offering unique advantages and applications. CCTV, or closed-circuit television, is one of the most widely used methods for pipe inspection. It involves inserting a camera into the pipeline to visually inspect the interior. This method is particularly effective for identifying blockages, cracks, and other visible defects. CCTV systems are favored for their ability to provide real-time video footage, allowing operators to make immediate assessments and decisions. The technology has evolved to include features like pan-and-tilt cameras, high-definition imaging, and remote control capabilities, enhancing its effectiveness in various inspection scenarios. Ultrasonic inspection, on the other hand, utilizes high-frequency sound waves to detect flaws within the pipe material. This non-destructive testing method is highly effective for identifying corrosion, wall thickness variations, and other subsurface anomalies. Ultrasonic inspection is particularly valuable in industries where maintaining the structural integrity of pipelines is critical, such as oil and gas and aerospace. The technology offers precise measurements and can be used on a wide range of materials, making it a versatile choice for many applications. Other technologies in the pipe inspection market include electromagnetic inspection, laser profiling, and infrared thermography. Electromagnetic inspection uses magnetic fields to detect metal loss and other defects in pipelines, while laser profiling provides detailed 3D models of the pipe interior, helping to identify deformations and other structural issues. Infrared thermography, meanwhile, detects temperature variations on the pipe surface, which can indicate leaks or insulation problems. Each of these technologies has its own set of advantages and limitations, and the choice of method often depends on the specific requirements of the inspection task. As the demand for more efficient and accurate inspection solutions grows, companies are increasingly integrating multiple technologies into their systems to provide comprehensive assessments. This trend is driving innovation in the market, with new products and solutions being developed to meet the evolving needs of industries. The integration of artificial intelligence and machine learning is also playing a significant role in enhancing the capabilities of pipe inspection systems, enabling more accurate data analysis and predictive maintenance. Overall, the diverse range of technologies available in the pipe inspection system market ensures that there is a solution for virtually every inspection challenge, making it a dynamic and rapidly evolving field.

Oil and Gas, Water and Sewer, Manufacturing, Aerospace in the Pipe Inspection System - Global Market:

Pipe inspection systems play a crucial role in several key industries, including oil and gas, water and sewer, manufacturing, and aerospace. In the oil and gas sector, pipelines are the lifelines that transport crude oil, natural gas, and refined products over vast distances. Ensuring the integrity of these pipelines is paramount to prevent leaks, spills, and other environmental hazards. Pipe inspection systems are used to regularly monitor the condition of pipelines, detecting corrosion, cracks, and other defects that could compromise their safety and efficiency. The use of advanced technologies like ultrasonic and electromagnetic inspection is common in this industry, providing precise data that helps operators make informed maintenance decisions. In the water and sewer industry, pipe inspection systems are essential for maintaining the infrastructure that delivers clean water and manages wastewater. CCTV inspection is widely used to identify blockages, leaks, and structural damage in water and sewer pipes. These systems help municipalities and utility companies ensure the reliability and safety of their services, preventing costly repairs and service disruptions. In the manufacturing sector, pipe inspection systems are used to monitor the condition of process pipelines that transport raw materials and finished products. Ensuring the integrity of these pipelines is critical to maintaining product quality and operational efficiency. Technologies like ultrasonic and laser profiling are often employed to detect wear and tear, corrosion, and other issues that could affect production. In the aerospace industry, pipe inspection systems are used to inspect the complex network of pipes and ducts that are integral to aircraft systems. Ensuring the integrity of these components is vital for the safety and performance of aircraft. Advanced inspection technologies, including ultrasonic and infrared thermography, are used to detect defects and ensure compliance with stringent safety standards. Overall, the use of pipe inspection systems in these industries highlights their importance in maintaining the safety, reliability, and efficiency of critical infrastructure.

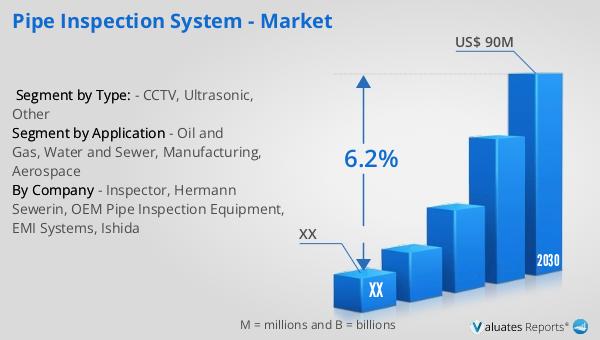

Pipe Inspection System - Global Market Outlook:

In 2023, the global pipe inspection system market was valued at approximately $61 million. It is projected to grow to around $90 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.2% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for reliable and efficient pipe inspection solutions across various industries. The North American market, a significant segment of the global market, also shows promising growth potential. Although specific figures for the North American market in 2023 and 2030 are not provided, it is expected to follow a similar growth trajectory as the global market. The rising need for infrastructure maintenance and the adoption of advanced inspection technologies are key drivers of this growth. As industries continue to prioritize safety, efficiency, and environmental compliance, the demand for pipe inspection systems is expected to rise, contributing to the market's expansion. The integration of innovative technologies, such as artificial intelligence and machine learning, is also anticipated to enhance the capabilities of pipe inspection systems, further fueling market growth. Overall, the pipe inspection system market is poised for significant development, driven by the increasing emphasis on maintaining the integrity and functionality of critical infrastructure.

| Report Metric | Details |

| Report Name | Pipe Inspection System - Market |

| Forecasted market size in 2030 | US$ 90 million |

| CAGR | 6.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Inspector, Hermann Sewerin, OEM Pipe Inspection Equipment, EMI Systems, Ishida |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |