What is Global Banding and Sealing Machines Market?

The Global Banding and Sealing Machines Market encompasses a wide array of equipment designed for wrapping or sealing products for secure shipment or storage. These machines play a crucial role in various industries, ensuring that goods are packaged in a manner that preserves their quality, prevents tampering, and facilitates easier transportation. Banding machines typically use materials like paper or plastic to tightly encircle a product or group of products, providing stability and sometimes even branding opportunities. Sealing machines, on the other hand, are used to seal containers like bags, pouches, or boxes, often with heat or adhesive, to protect the contents from external elements and contamination. This market's significance is underscored by its utility across numerous sectors, including food and beverage, pharmaceuticals, consumer goods, and logistics, among others. As businesses continue to prioritize efficiency and product safety, the demand for advanced banding and sealing solutions is expected to rise, driving market growth globally. This sector's evolution is marked by innovations aimed at enhancing speed, reliability, and environmental sustainability, reflecting the industry's response to the changing needs of modern commerce.

Fully Automatic Type, Semi-automatic Type in the Global Banding and Sealing Machines Market:

Diving into the Global Banding and Sealing Machines Market, we find it segmented into fully automatic and semi-automatic types, each catering to different operational scales and requirements. Fully automatic banding and sealing machines are designed for high-volume production environments where speed and consistency are paramount. These machines automate the entire process of packaging, from feeding the products to applying the band or seal, all the way to ejecting the finished product for further handling. This automation not only significantly increases production rates but also reduces labor costs and minimizes the risk of human error, ensuring a uniform output that meets stringent quality standards. On the other hand, semi-automatic machines require more human intervention but offer flexibility and adaptability for smaller production runs or products that demand a more hands-on approach. These machines are ideal for businesses that handle a wide variety of products or those that are scaling up operations and are not yet ready to invest in fully automated systems. Both types of machines incorporate modern technology to accommodate a range of materials and sealing methods, allowing for customization to meet specific packaging needs. Innovations in machine design focus on improving efficiency, reducing waste, and enhancing user safety, reflecting the industry's commitment to sustainable practices and workplace wellbeing. As the market evolves, the distinction between fully automatic and semi-automatic machines continues to blur, with manufacturers offering modular designs that can be upgraded from semi to fully automatic functionality, providing businesses with scalable solutions that grow with their needs.

Pharmaceutical Company, Biological Company, Other in the Global Banding and Sealing Machines Market:

In the realm of the Global Banding and Sealing Machines Market, their application within pharmaceutical companies, biological companies, and other sectors highlights their indispensable role in ensuring product integrity and compliance with stringent industry standards. For pharmaceutical companies, these machines are vital in packaging medications in a way that protects them from contamination, ensures dosage accuracy, and extends shelf life. The precision and reliability of banding and sealing machines are paramount in this sector, where the consequences of packaging failures can be severe. Biological companies, dealing with products like vaccines, specimens, and biological reagents, require packaging solutions that offer not only security but also temperature control and tamper evidence. The specialized needs of these companies have spurred innovations in banding and sealing technologies, including the integration of advanced materials and sealing methods that can withstand extreme conditions. Beyond these sectors, banding and sealing machines find applications in a myriad of industries, from food and beverage to electronics, where they contribute to product safety, brand presentation, and logistical efficiency. The versatility of these machines, capable of handling a wide range of product sizes, shapes, and types, underscores their importance in modern manufacturing and distribution processes. As companies across all sectors strive to meet the growing demands for sustainability, traceability, and consumer safety, the global banding and sealing machines market continues to evolve, offering solutions that not only meet these challenges but also drive operational excellence.

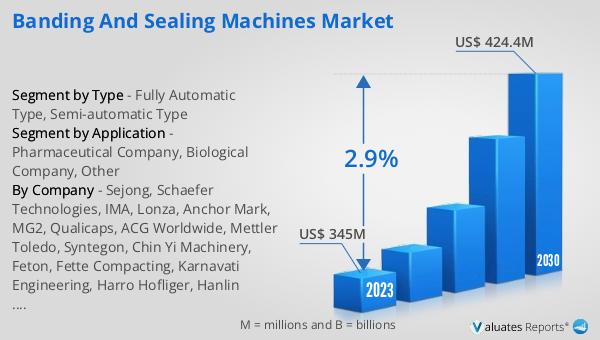

Global Banding and Sealing Machines Market Outlook:

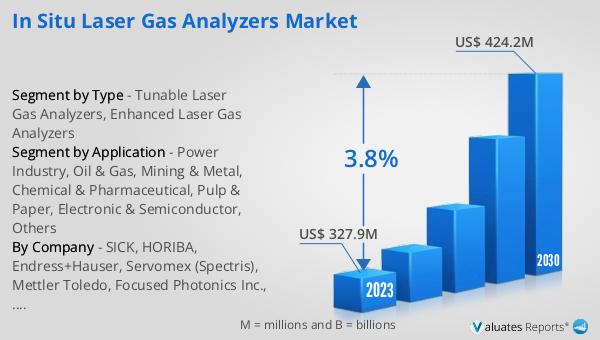

The market outlook for the Global Banding and Sealing Machines Market presents a promising future. In 2023, the market's value was recorded at US$ 345 million, with projections indicating a growth to US$ 424.4 million by 2030. This growth trajectory, representing a Compound Annual Growth Rate (CAGR) of 2.9% during the forecast period from 2024 to 2030, underscores the increasing demand and potential within this sector. The competitive landscape of this market is notably concentrated, with the top five manufacturers collectively holding a share of over 35%. This concentration highlights the presence of key players who are significantly influencing market dynamics through innovation, quality, and service. The anticipated growth is reflective of the expanding applications of banding and sealing machines across various industries, driven by the need for efficient, reliable, and secure packaging solutions. As businesses continue to seek ways to optimize their packaging processes, reduce waste, and enhance product safety, the demand for banding and sealing machines is expected to rise, further propelling the market forward. This outlook not only showcases the market's current state but also its potential for future growth, offering insights into the opportunities and challenges that lie ahead.

| Report Metric | Details |

| Report Name | Banding and Sealing Machines Market |

| Accounted market size in 2023 | US$ 345 million |

| Forecasted market size in 2030 | US$ 424.4 million |

| CAGR | 2.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sejong, Schaefer Technologies, IMA, Lonza, Anchor Mark, MG2, Qualicaps, ACG Worldwide, Mettler Toledo, Syntegon, Chin Yi Machinery, Feton, Fette Compacting, Karnavati Engineering, Harro Hofliger, Hanlin Hangyu Industrial, Zhejiang Fuchang Machinery, Adinath International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |